Ultrahigh-reflectivity composite material and preparation method thereof

A composite material and ultra-high technology, applied in the field of ultra-high reflection composite materials and their preparation, to achieve good corrosion resistance and weather resistance, improve total reflectivity, and protect metal coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

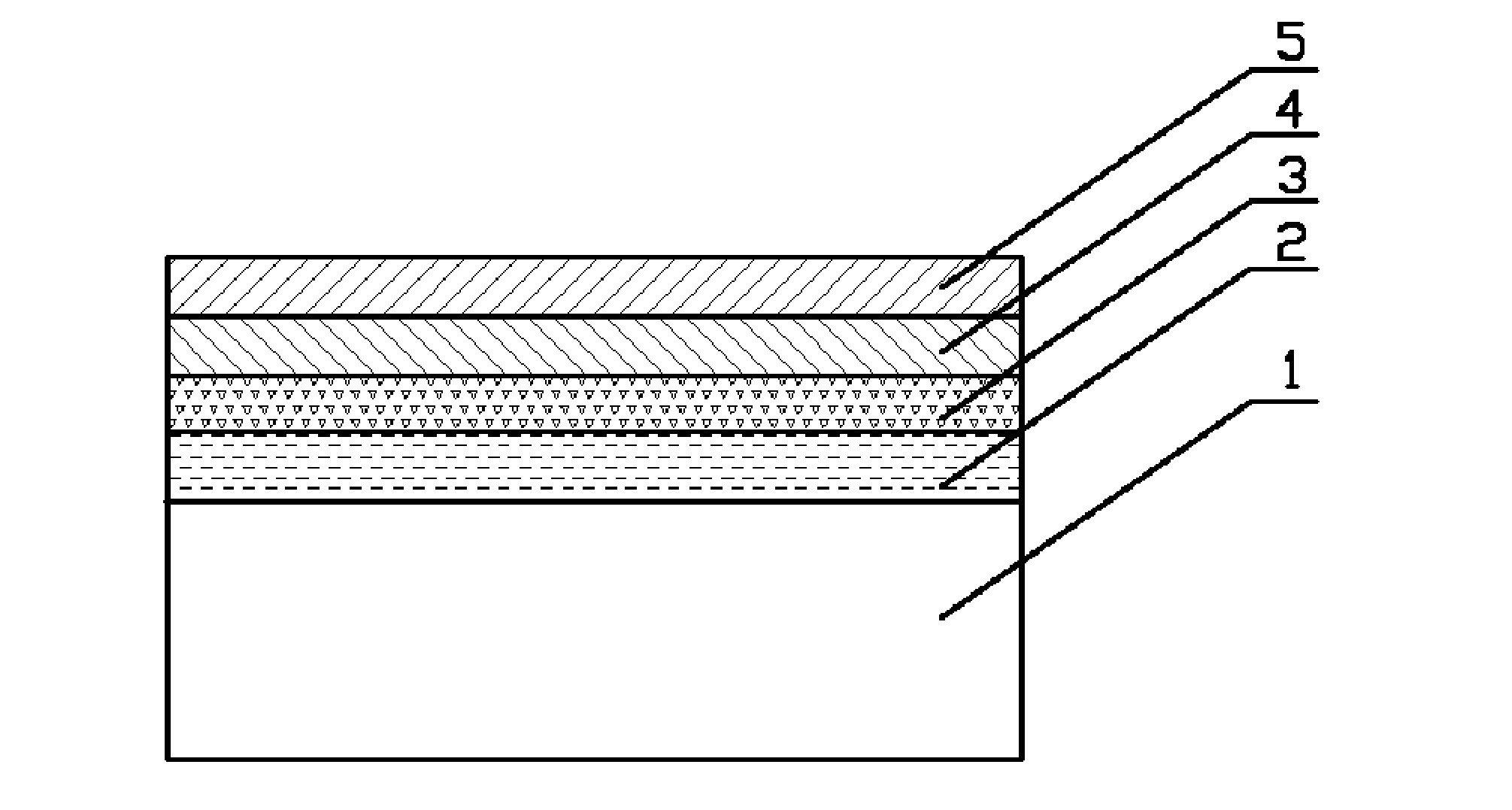

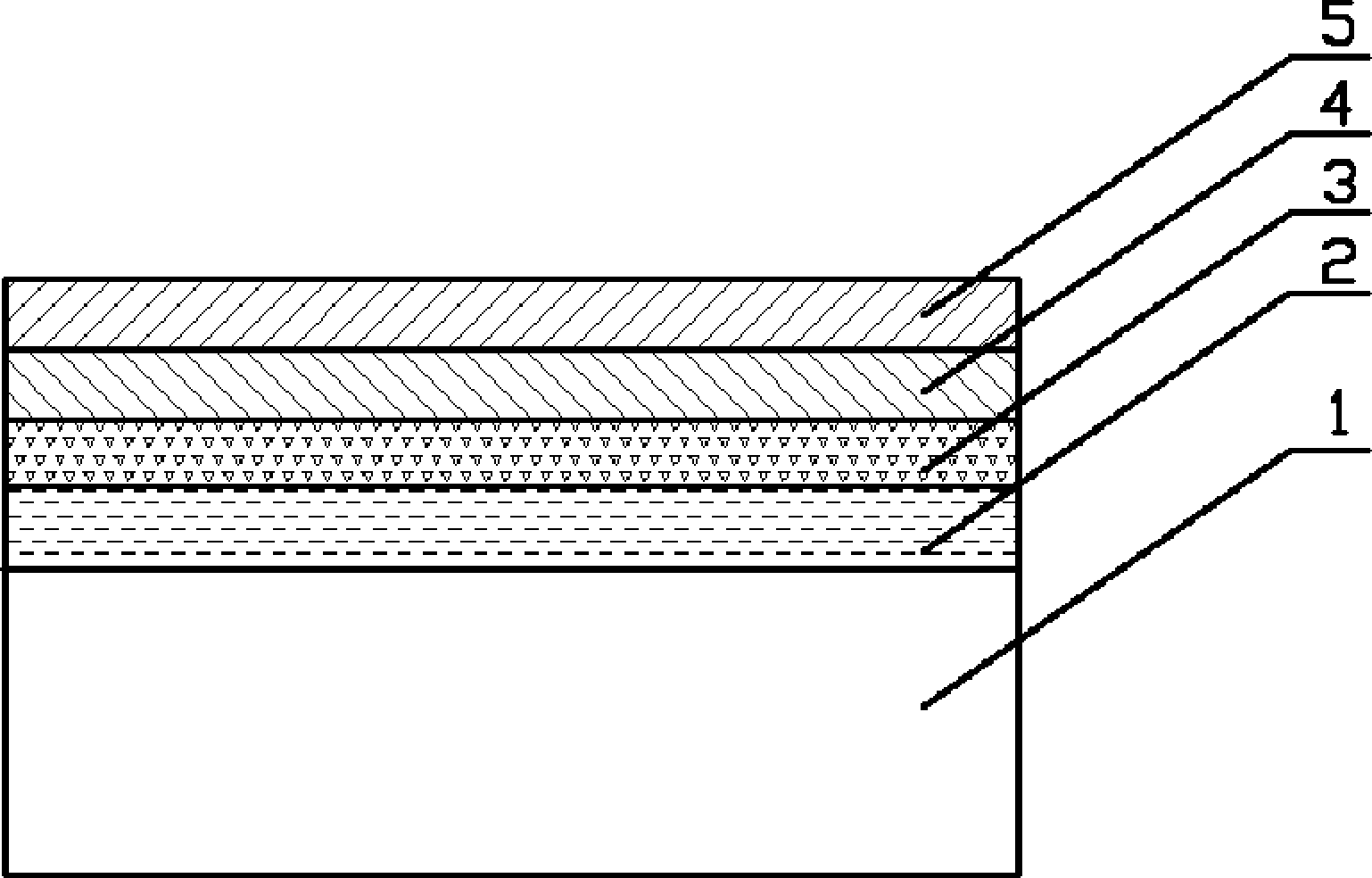

[0024] Such as figure 1 As shown, the ultra-high reflection composite material of this embodiment includes a substrate 1, an affinity layer 2, a metal coating 3 and a protective layer. The protective layer includes a first protective layer 5 and a second protective layer 4. The substrate 1, the affinity layer And layer 2, metal plating layer 3, second protective layer 4 and first protective layer 5 are covered sequentially from bottom to top. The substrate 1 is a metal material, including aluminum, iron, copper, etc.; the affinity layer 2 is a porous layer with a thickness of 1 μm-4 μm; the metal plating layer is an aluminum-coated layer with a purity of 99.99%, and its thickness is 0.05 μm-1 μm; The second protective layer is a fluoride coating with a thickness of 0.03 μm-3 μm; the first protective layer is an oxide coating with a thickness of 0.03 μm-3 μm.

Embodiment 2

[0026] The ultra-high reflection composite material in the above embodiment is prepared by the preparation method in this embodiment.

[0027] A method for preparing an ultra-high reflection composite material, comprising the following steps:

[0028] In the first step, an aluminum plate is selected as the substrate 1, and then a 1.5 μm porous oxide film is prepared on the aluminum plate by anodizing, which is the affinity layer 2;

[0029] In the second step, a 0.05 μm aluminum coating with a purity of 99.99% is obtained on the affinity layer 2 by magnetron sputtering, which is the metal coating 3;

[0030] The third step is to attach a 0.06 μm magnesium fluoride coating on the metal coating 3 by thermal evaporation method, that is, the second protective layer 4;

[0031] The fourth step is to prepare a 0.1 μm titanium dioxide coating on the second protective layer 4 by sputtering, that is, the first protective layer 5 , so as to prepare a composite material with super high ...

Embodiment 3

[0035] This embodiment is a modification of Embodiment 2, and the difference lies in that different metal materials are used as the base materials.

[0036] In the present invention, the reflectivity structure comparison of different material substrates is as follows:

[0037] Substrate

[0038] From the above results, it can be seen that substrates of different materials have different reflectivity, and relatively speaking, copper and aluminum have better reflection effects when used as substrates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com