Preparation method of gradually-varied PET film

A kind of equipment and optical thin film technology, applied in the field of gradient PET film preparation, can solve the problems of natural transition, convex change, and inability to form gradient film effects, etc., and achieve multifunctional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

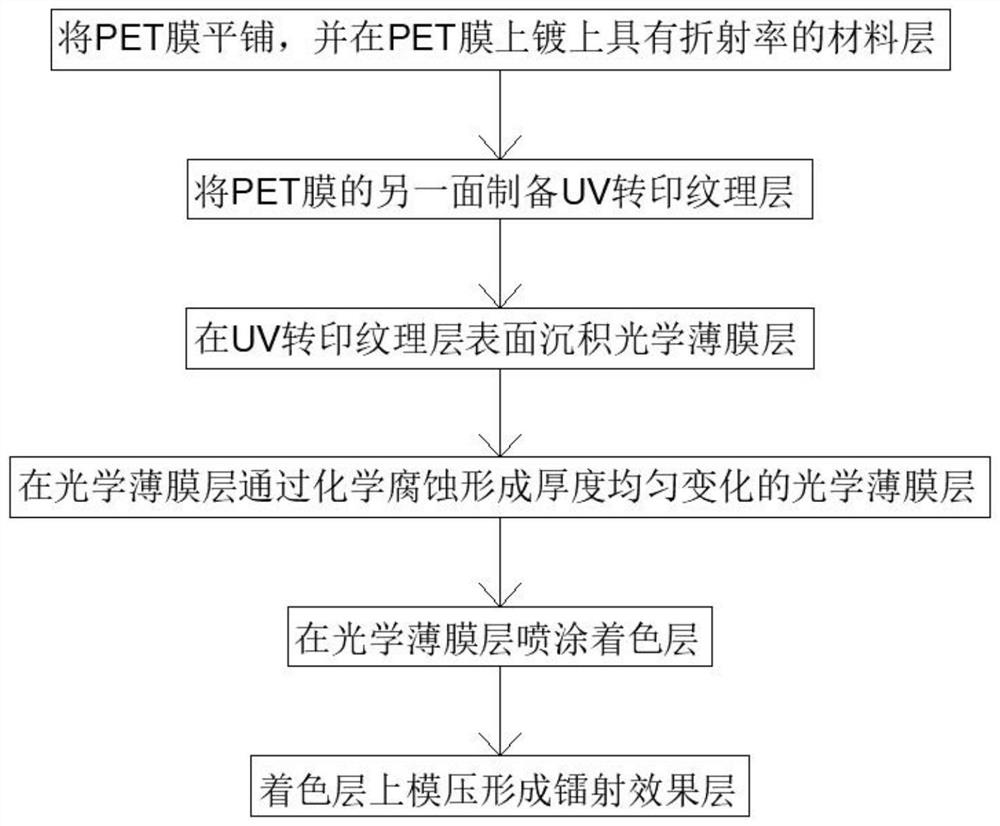

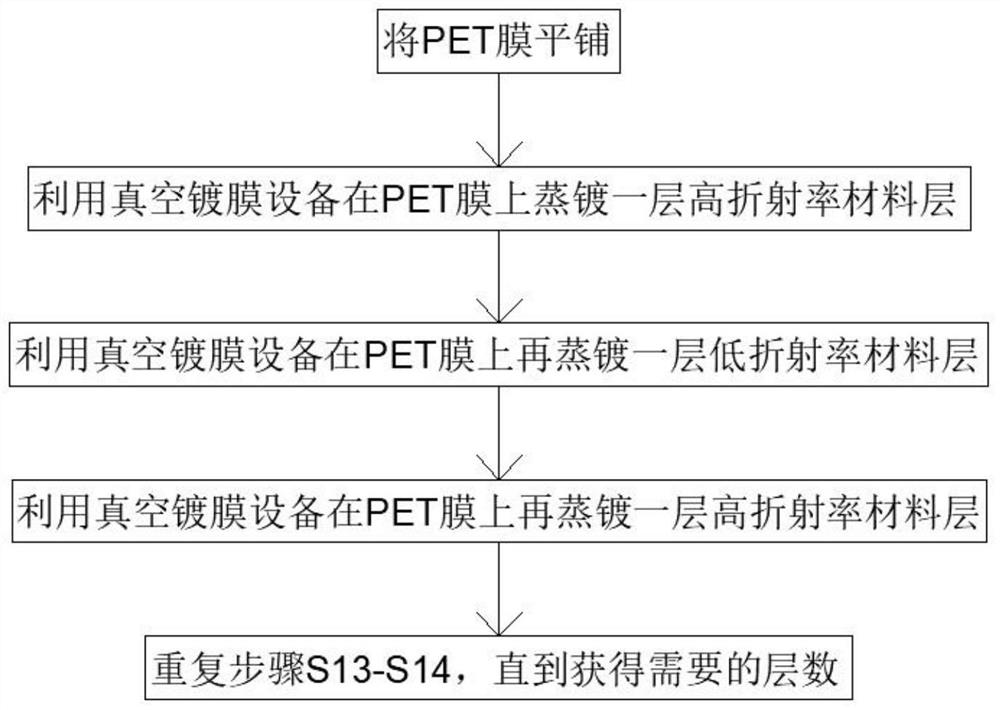

[0036] see Figure 1-3 , in an embodiment of the present invention, a method for preparing a graded PET film, comprising the following steps: S1: flatten the PET film, and coat the PET film with a material layer having a refractive index;

[0037] S2: Prepare a UV transfer printing texture layer on the other side of the PET film;

[0038] S3: Depositing an optical film layer on the surface of the UV transfer texture layer;

[0039] S4: forming an optical film layer with a uniform thickness by chemical etching on the optical film layer;

[0040] S5: Spraying the coloring layer on the optical film layer;

[0041] S6: forming a laser effect layer by molding on the colored layer.

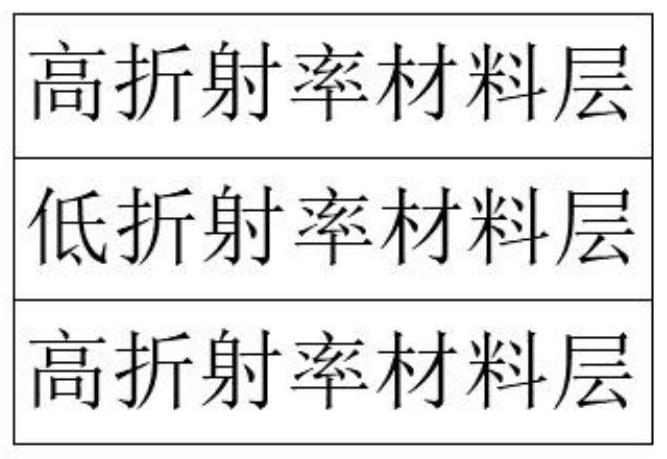

[0042] Preferably, in the step S1, the layer of material having a refractive index coated on the PET film is composed of alternating high refractive index material layers and low refractive index material layers.

[0043] Preferably, the high refractive index material layer and the low refractive in...

Embodiment 2

[0057] see figure 1 , figure 2 with Figure 4 , in an embodiment of the present invention, a method for preparing a graded PET film, comprising the following steps: S1: flatten the PET film, and coat the PET film with a material layer having a refractive index;

[0058] S2: Prepare a UV transfer printing texture layer on the other side of the PET film;

[0059] S3: Depositing an optical film layer on the surface of the UV transfer texture layer;

[0060] S4: forming an optical film layer with a uniform thickness by chemical etching on the optical film layer;

[0061] S5: Spraying the coloring layer on the optical film layer;

[0062] S6: forming a laser effect layer by molding on the colored layer.

[0063] Preferably, in the step S1, the layer of material having a refractive index coated on the PET film is composed of alternating high refractive index material layers and low refractive index material layers.

[0064] Preferably, the high refractive index material layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com