Method for producing acid whey by using whey water

A technology for whey water and yogurt, applied in the directions of bacteria, whey, and application used in food preparation, can solve the problem of research on standardized production methods of unseen acid water, affecting the edible safety of milk fans and milk cakes, affecting milk fans and problems such as milk cake output, to achieve the effect of good resource reuse, reduction of fermentation cycle, and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

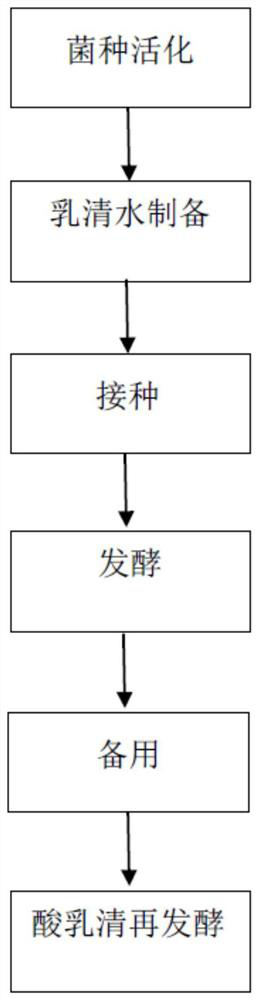

[0027] 1. Activation of strains

[0028] Inoculate the acid whey fermentation strain into the MRS medium, the inoculum amount is 10% of the MRS medium, activate to the third generation, the activation temperature is 35°C, the first generation is activated for 22 hours, the second generation is activated for 24 hours, and the second generation is activated for 24 hours. The third generation was activated for 24 hours, and the total activation was 70 hours. The MRS medium was purchased from: Sigma Company. The acid whey fermentation strains are Lactobacillus fermentum and Lactobacillus bulgaricus: the two acid whey fermentation strains are activated respectively.

[0029] Lactobacillus fermentum and Lactobacillus bulgaricus were purchased from Yunnan Huangshi Laisier Dairy Co., Ltd. respectively.

[0030] 2. Preparation of whey water

[0031] Sterilize the remaining whey after making the milk fan or milk cake. The specific operation is to boil the whey for 5 minutes, filter, ...

Embodiment 2

[0042] 1. Activation of strains

[0043] Inoculate the acid whey fermentation strains into the MRS medium, the inoculum amount is 10% of the MRS medium, activate to the third generation, the activation temperature is 37°C, the first generation is activated for 24 hours, the second generation is activated for 24 hours, and the third generation is activated for 24 hours. Generation activation for 24 hours, co-activation for 72 hours. The MRS medium was purchased from: Sigma Company. The acid whey fermentation strains were Lactobacillus fermentum and Lactobacillus bulgaricus purchased from Yunnan Huangshi Laisier Dairy Co., Ltd. respectively, and the two acid whey fermentation strains were respectively activated.

[0044] 2. Preparation of whey water

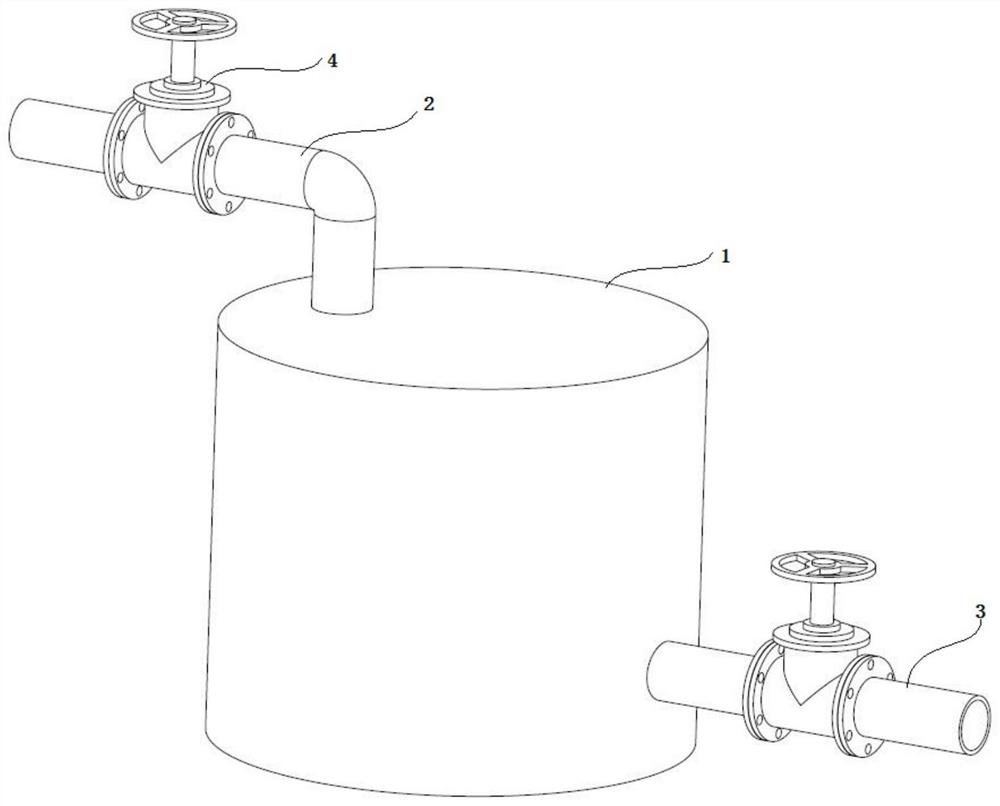

[0045] Sterilize the remaining whey after making the milk fan or milk cake. The specific operation is to boil the whey for 8 minutes, filter, and put it into the sterilized fermenter 1 to cool to room temperature. The fermenter ...

experiment example 3

[0056] 1. Activation of strains

[0057] Inoculate the acid whey fermentation strain into the MRS medium, the inoculum amount is 10% of the MRS medium, activate to the third generation, the activation temperature is 36°C, the first generation is activated for 23 hours, the second generation is activated for 24 hours, and the third generation is activated for 24 hours. Generation activation for 24h, co-activation for 71h. The MRS medium was purchased from: Sigma Company. The acid whey fermentation strains are Lactobacillus fermentum and Lactobacillus bulgaricus: the two acid whey fermentation strains are activated respectively.

[0058] Lactobacillus fermentum and Lactobacillus bulgaricus were purchased from Yunnan Huangshi Laisier Dairy Co., Ltd. respectively.

[0059] 2. Preparation of whey water

[0060] Sterilize the remaining whey after making the milk fans or milk cakes. The specific operation is to boil the whey for 6 minutes, filter, and put it into the sterilized fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com