Air compressor crank double-end synchronous positioning and clamping device

A technology of synchronous positioning and clamping devices, which is applied in the direction of positioning devices, clamping, metal processing machinery parts, etc., can solve the problems of difficult synchronization of position adjustment, low precision of parts processing, and inability to meet processing requirements, etc., to increase the adjustment stroke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

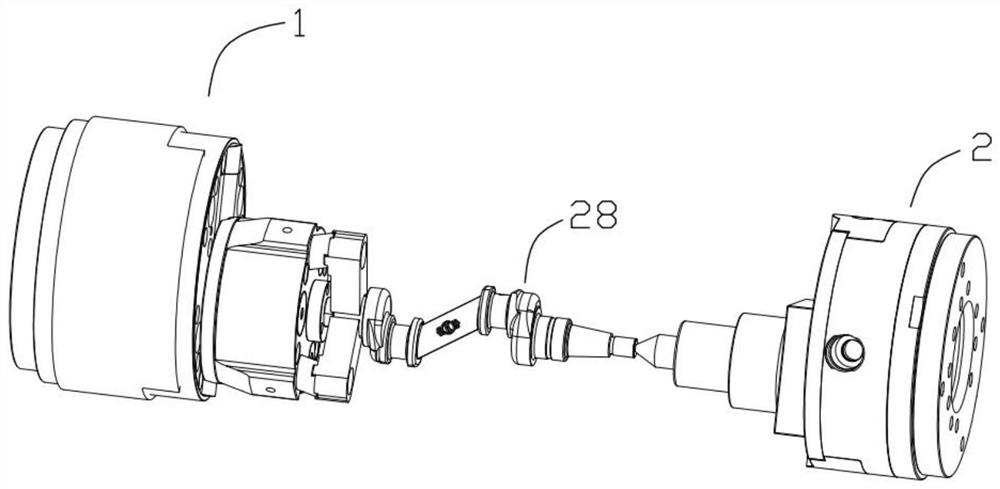

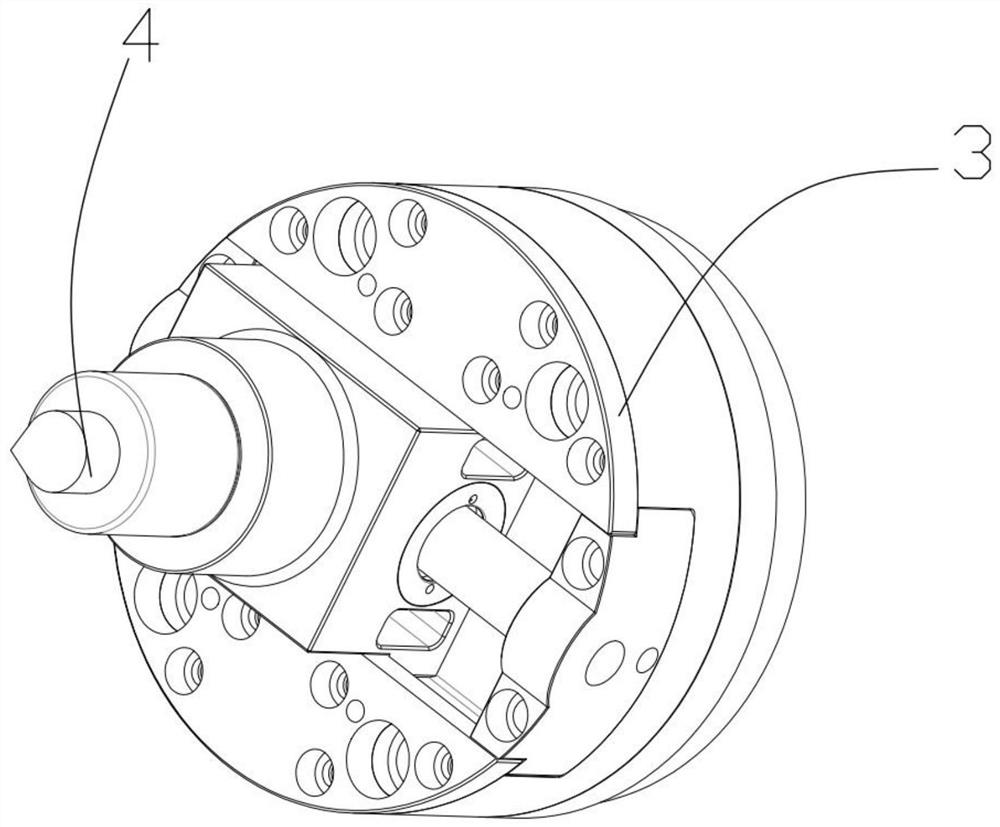

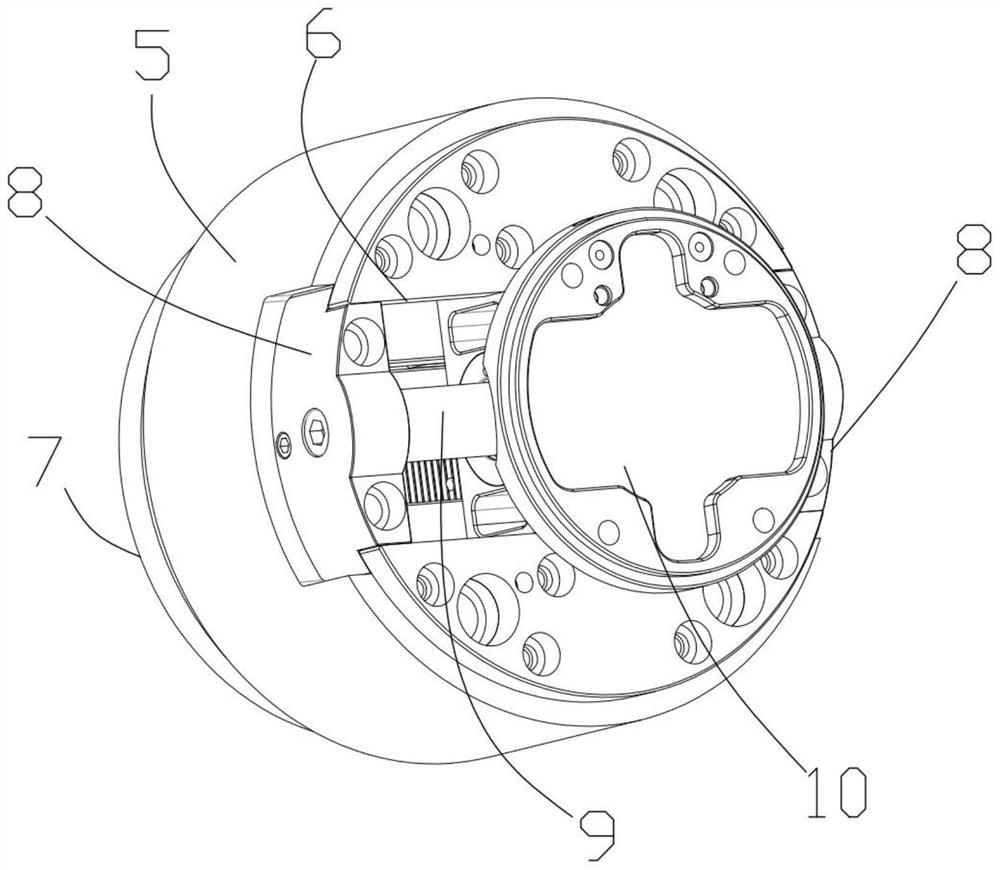

[0027] Such as figure 1 , figure 2 As shown, the present invention proposes an air compressor crank dual-head synchronous positioning and clamping device, which includes a clamping mechanism 1 and a positioning mechanism 2 that are oppositely arranged. The clamping mechanism 1 and the positioning mechanism 2 include hydraulically driven Mobile components 3, such as image 3 As shown, the function of the clamping mechanism 1 is to fix one end of the crank 28, and adjust the center position of the crank 28 according to the center of the disc to be processed. The function of the positioning mechanism 2 is to position the other end of the crank 28, and follow this The adjustment of the position of the clamping mechanism 1 is adjusted, so the clamping mechanism 1 and the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com