Refrigerator car

A technology for refrigerated trucks and carriages, which is applied to vehicle components, heating/cooling equipment, and the superstructure of trucks, etc., can solve the problems of easy cavitation, complicated construction, and difficult positioning of finished products, and is not easy to leak cold. And water leakage, ensure product quality, improve the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

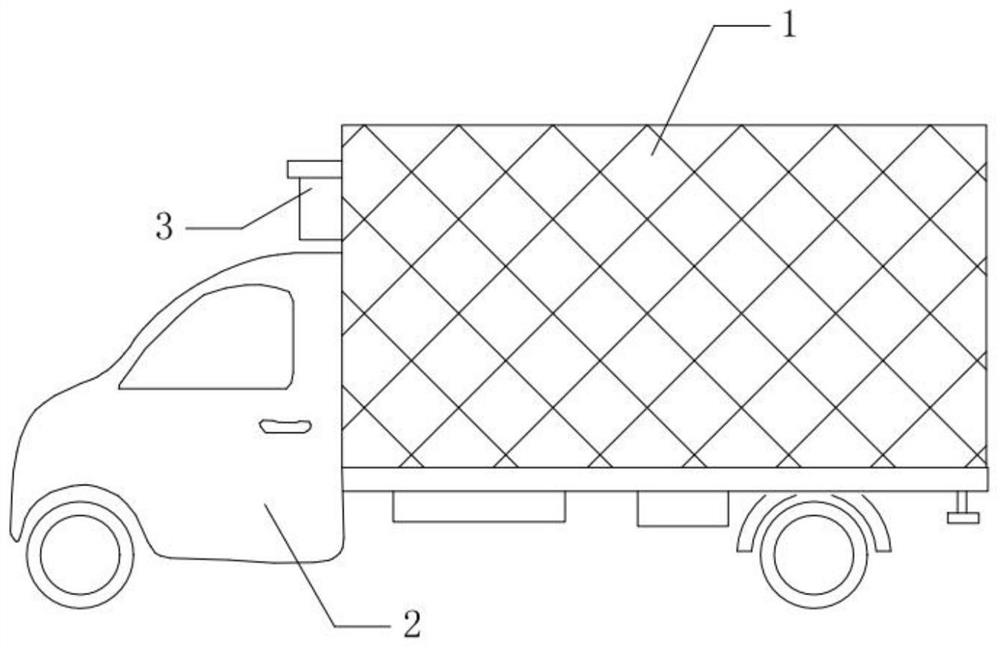

[0067] A refrigerated vehicle such as figure 1 As shown, including car body 2, heat-insulated compartment 1 and refrigeration unit 3, car body 2 and refrigeration unit 3 are all realized by existing technology, heat-insulated compartment 1 is arranged on the vehicle frame of car body 2, and refrigeration unit 3 is set In the insulated compartment 1 , the refrigerating unit 3 is used to discharge the heat in the insulated compartment 1 .

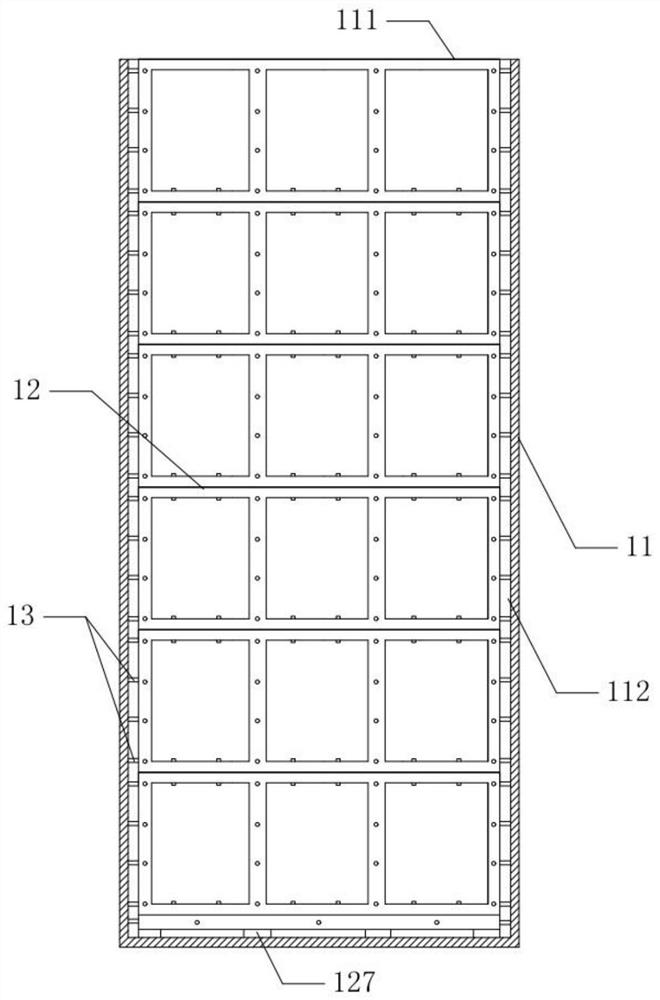

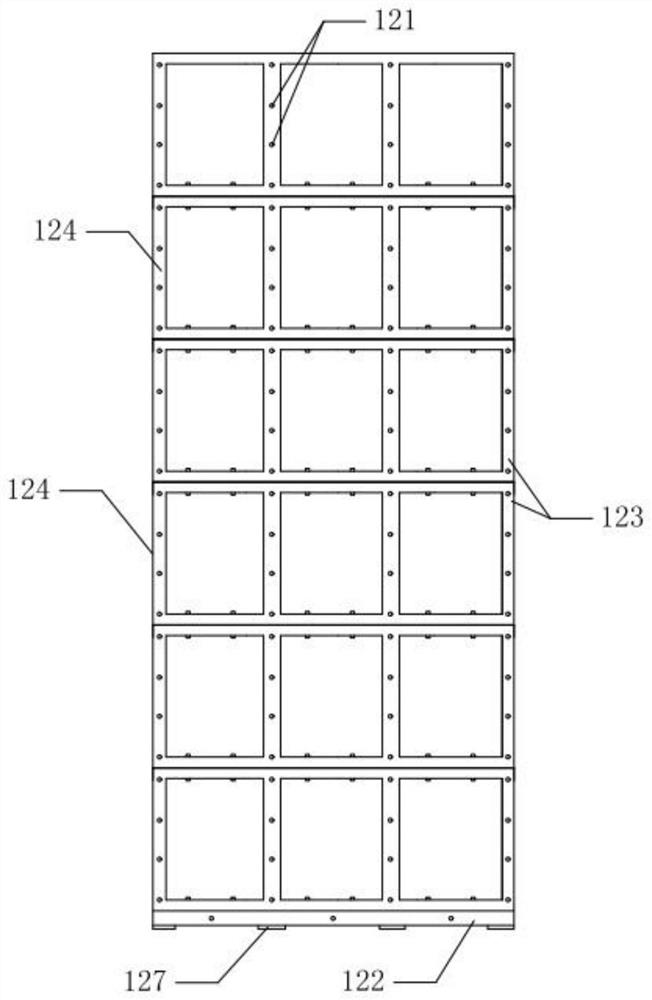

[0068] Please refer to figure 2 and image 3 , the insulated compartment 1 includes an outer compartment 11, a frame 12, connecting bolts 13 and an annular end plate 14 (such as Figure 9 shown); the outer box body 11 and the skeleton 12 are cuboid structures, and one end of the outer box body 11 is provided with an opening 111, and the inner peripheral wall of the outer box body 11 is provided with a fastening mechanism 4. The outer box body 11 is integrally formed, and the material of the outer box body 11 is fiberglass.

[0069] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com