Polylactic acid modified material for food contact injection molding products and preparation method thereof

A modified material and food contact technology, applied in the field of polymer materials, can solve the problems of expensive, limited polylactic acid industrial application and large-scale development, and achieve the effect of simple and efficient cost and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

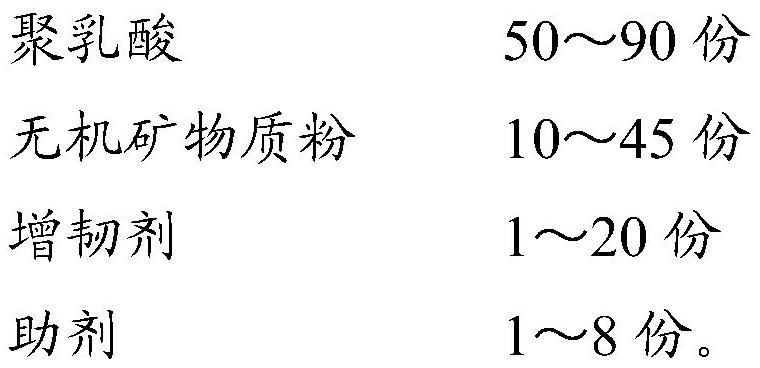

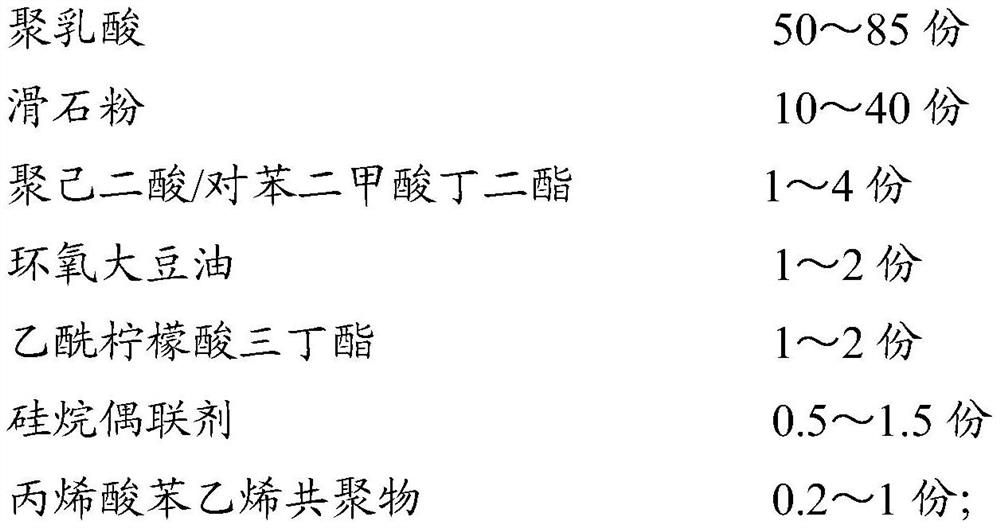

Method used

Image

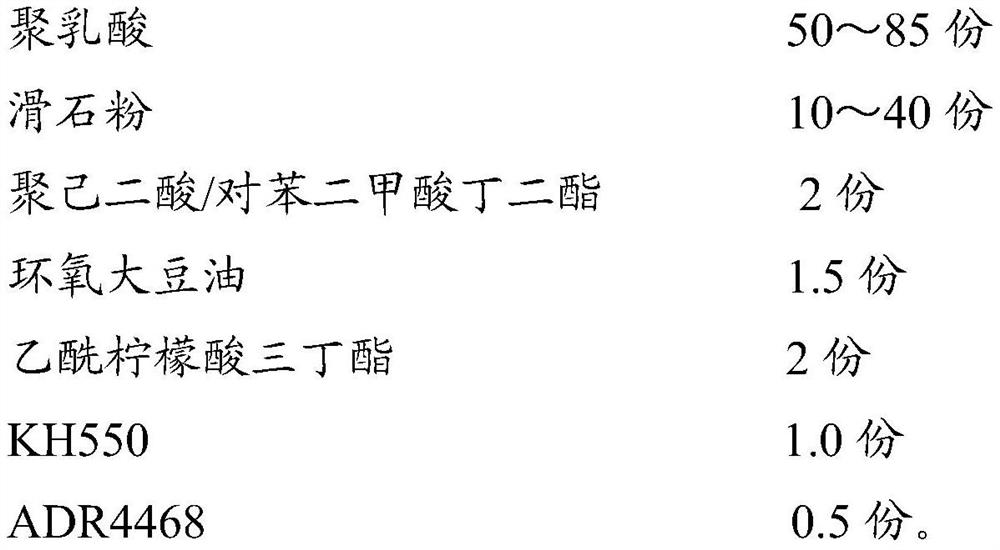

Examples

preparation example Construction

[0057] The preparation method of above each embodiment polylactic acid modified material comprises the following steps:

[0058] (1) Mix polylactic acid PLLA with a toughening agent and an auxiliary agent to obtain component A, and component A is extruded through the first twin-screw unit to obtain molten component A;

[0059] The molten component A is mixed with the inorganic mineral powder in the second twin-screw unit, and then extruded, cooled, and pelletized to obtain the polylactic acid modified granular material.

[0060] Among them, the first twin-screw unit is divided into 10 zones, and the temperature of each zone is 155-160°C, 160-165°C, 165-170°C, 170-175°C, 175-180°C, 175-180°C, 180-185°C ℃, 185~190℃, 190~195℃, 195~200℃;

[0061] The second twin-screw unit is divided into 10 zones, and the temperature of each zone is 195-200°C, 190-195°C, 185-190°C, 180-185°C, 175-180°C, 170-175°C, 175-180°C, 165~170℃, 160~165℃, 160~165℃.

[0062] Afterwards, the properties of ...

Embodiment 11

[0075] Example 11 The raw materials of polylactic acid were mixed at a weight ratio of PLLA:PDLA=60:40 to establish a blended stereosystem of PDLA / PLLA.

Embodiment 12

[0076] Embodiment 12 uses high-purity PDLA.

[0077] Afterwards, the properties of the prepared polylactic acid modified materials were tested. The polylactic acid modified granular material prepared in each example was made into a sample strip, and crystallized in the mold for 20 s in the preparation of the sample strip, and the mold temperature was 105°C. The test results are shown in Table 5.

[0078] table 5

[0079]

[0080] Compared with Example 4 in which L-polylactic acid (PLLA) was used alone, the performance data of Example 11 showed that the physical properties of the polylactic acid modified granular products prepared by the blended stereosystem of PDLA / PLLA were enhanced, and the impact strength Improve; the system has the characteristics of high crystallinity and high heat deformation resistance.

[0081] The performance test results of Example 11 and Example 12 also show that with the increase of PDLA content, the heat resistance of the product is greatly i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com