Preparation device and preparation method of large-diameter diamond wafer

A diamond sheet and preparation device technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve the problems of expensive equipment, difficult peeling, difficult splicing, etc., to achieve good quality and high production efficiency High, simple process and equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

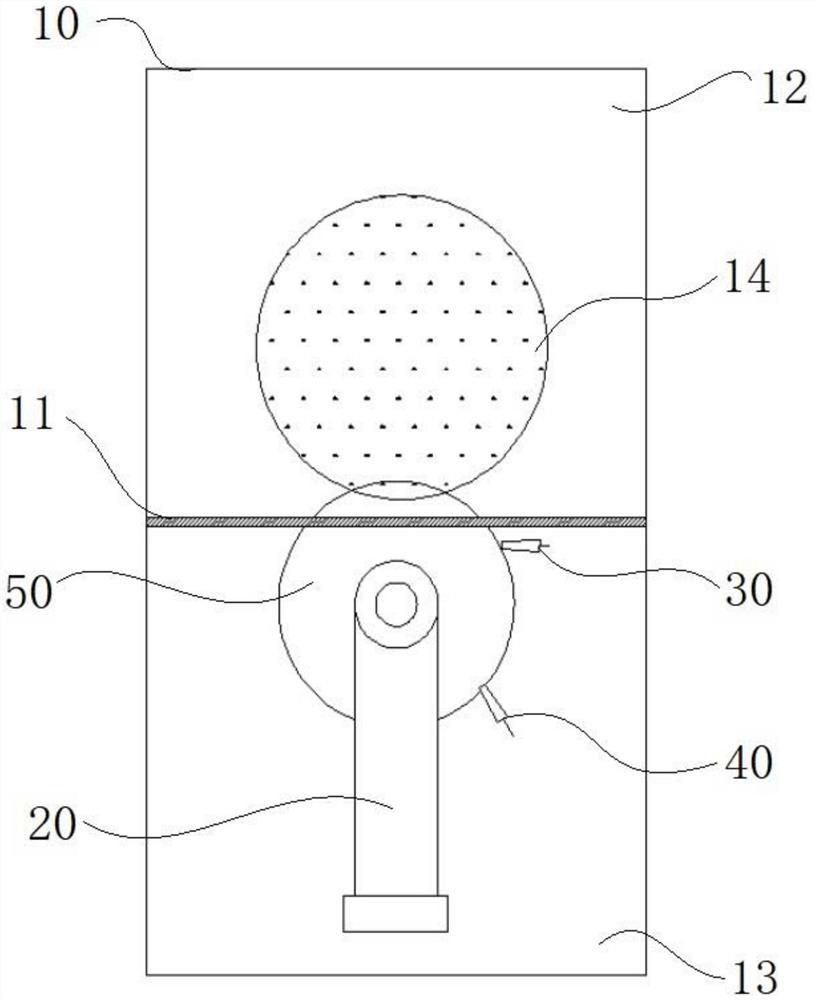

[0047] This embodiment provides a large-diameter diamond sheet preparation device with a simple foundation, including a housing 10, a slit partition 11, an elevating rotating support 20, a diameter detection unit 30 and a mask unit 40, the slit partition The plate 11 is provided with a through hole 15 that can pass through the diamond disc 50. The lifting type rotating bracket 20 includes a lifting rod device 21, a rotating motor 22 and a rotating shaft 23. The rotating shaft 23 is provided with a mounting position. The diamond disc 50 Adhered to the mounting position, the mask unit 40 includes a set of graphite masks, which are clamped on both sides of the diamond wafer 50 .

no. 2 example

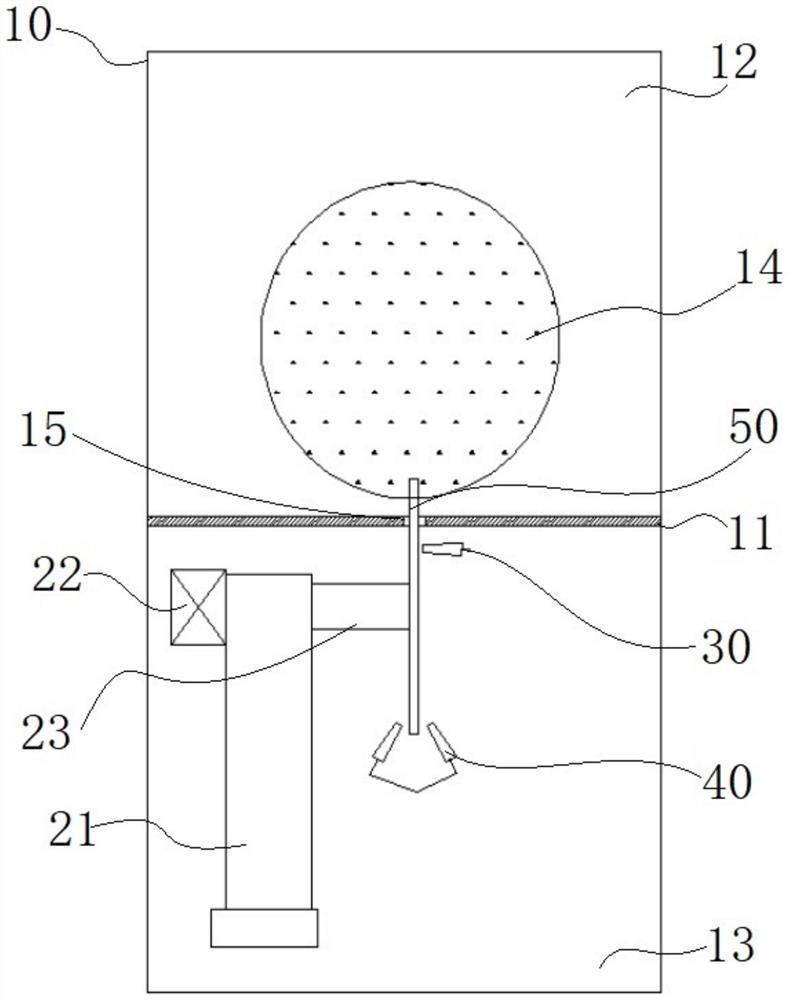

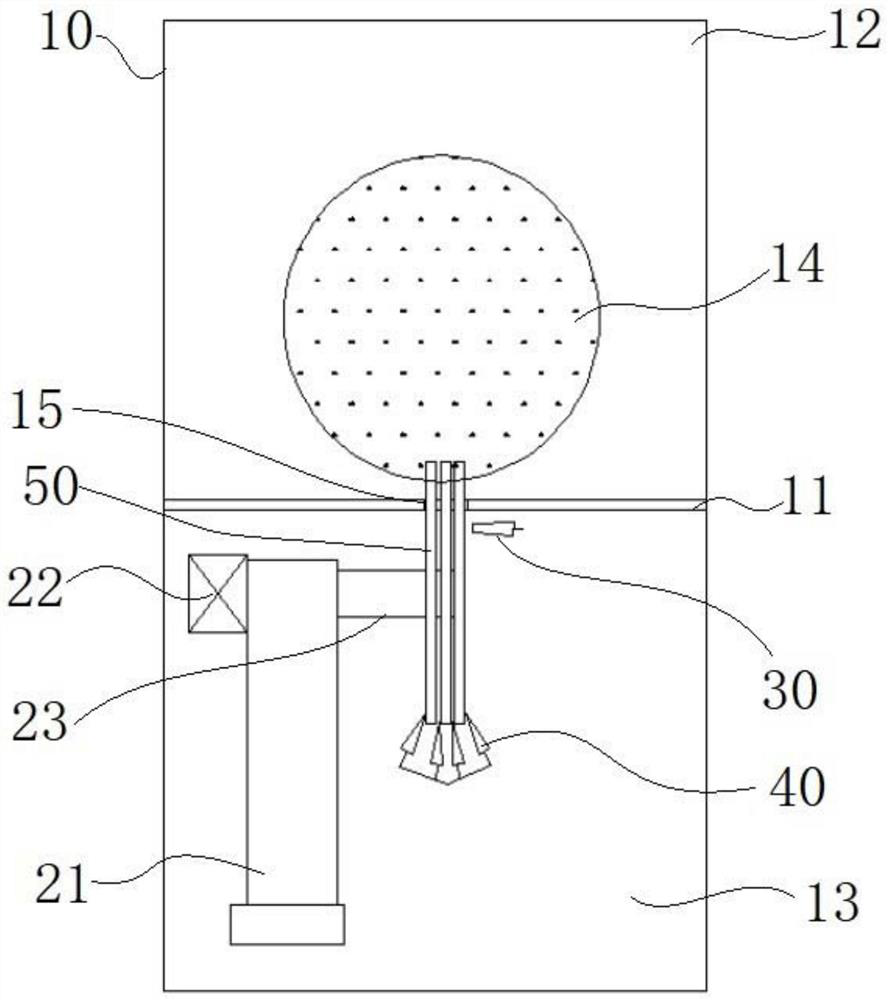

[0049] This embodiment provides a preparation device capable of producing multiple large-diameter diamond sheets at the same time, including a housing 10, a slit partition 11, an elevating rotating support 20, a diameter detection unit 30 and a mask unit 40, narrowly The slit partition 11 is provided with three through holes 15 through which the diamond disc 50 can pass. The lifting type rotating bracket 20 includes a lifting rod device 21, a rotating motor 22 and a rotating shaft 23. The rotating shaft 23 is provided with three installation positions, three The diamond discs 50 are bonded to corresponding installation positions respectively. The mask unit 40 includes three sets of graphite masks, and the three sets of graphite masks are respectively clamped on both sides of the corresponding diamond discs 50 . In this embodiment, the number of growths is increased by increasing the installation positions of the rotating shaft 23 .

[0050] see Figure 4 Shown, the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com