A new self-stabilizing valve

A self-stabilizing and valve technology, which is applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve the problems of grease injection port blockage, grease injection port sealing, and pressure control, etc., to achieve convenient rotation and buffer grease injection The pressure and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

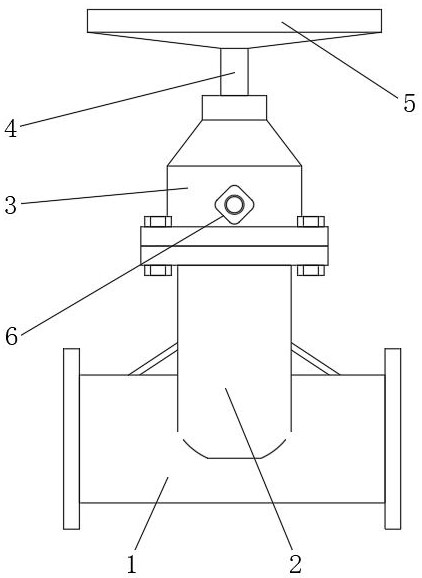

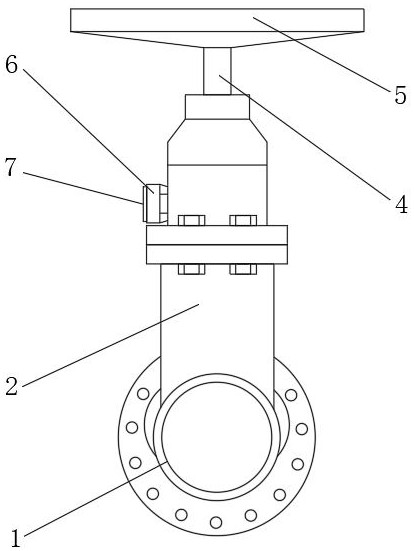

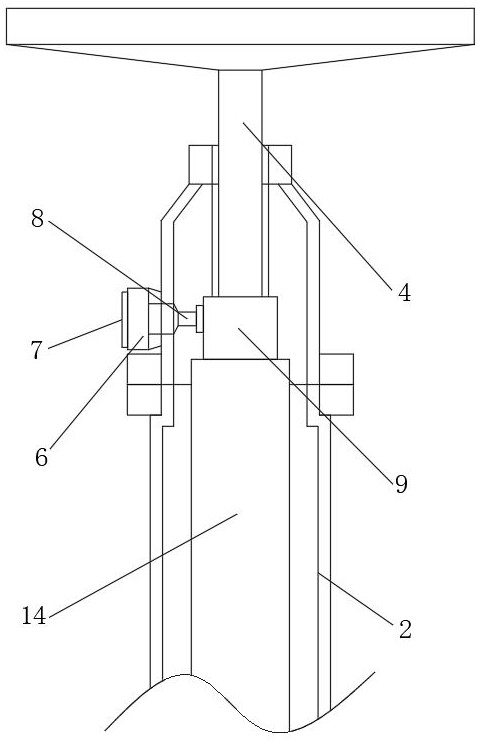

[0041] see Figure 1-8, a new type of self-stabilizing valve, including a valve body 1, a flow control box 2 is fixedly installed on the top of the center of the valve body 1, the upper end of the flow control box 2 is fixedly connected to a valve cover 3, and the internal rotation of the valve cover 3 is connected to There is a valve stem 4, a handle 5 is fixedly installed on the top of the valve stem 4, a grease injection port 6 is fixedly installed on the front end of the valve cover 3, a seal block 7 is connected to the inside of the grease injection port 6, and the rear end of the grease injection port 6 is fixed A control pipeline 8 is connected, and a buffer sleeve 9 is fixedly installed on the rear side of the control pipeline 8, and a positioning shaft 14 is fixedly installed on the bottom of the buffer sleeve 9. The inner side wall of the buffer sleeve 9 is provided with a positioning groove 13, and the positioning groove 13 A binding piece 10 is connected inside, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com