Gas pipeline leakage detection device and method based on infrasonic waves

A technology for leak detection device and gas pipeline, which is applied to measuring device, can solve the problems of false alarm of operation status, missed detection of small leaks, pipeline leakage, etc. by detecting the appearance of fluid at the leak point, pipeline system, etc. The effect of increased performance, strong operability, and small observation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

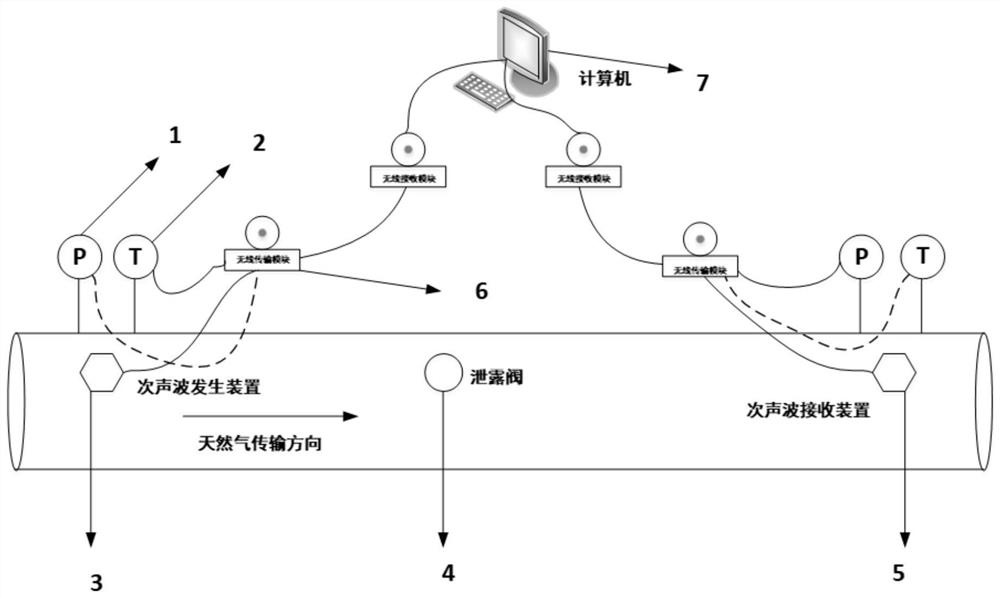

[0064] Embodiment 1: as figure 1 As shown, a gas pipeline leakage detection device based on infrasonic waves includes a pressure sensing component, a temperature sensing component, an infrasonic wave generating device 3, an infrasonic wave receiving device 5, a leakage valve 4 and a computer, a pressure sensing component 1, a temperature sensor The sensing member 2, the infrasonic wave generating device 3, and the infrasonic wave receiving device 5 are all arranged on the gas transmission pipeline, the infrasonic wave generating device 3 is located upstream of the infrasonic wave receiving device 5, and the leakage valve 4 is arranged on the gas transmission pipeline and located between the infrasonic wave generating device 3 and the infrasonic wave receiving device. Between the devices 5, the pressure sensing component, the temperature sensing component, the infrasonic wave generating device 3, the infrasonic wave receiving device 5, and the leakage valve 4 are all connected t...

Embodiment 2

[0070] Embodiment 2: The gas pipeline leakage detection method based on infrasonic waves adopts the gas pipeline leakage detection device based on infrasonic waves in Embodiment 1, and the specific steps are as follows:

[0071] (1) The leakage valve of the computer is closed, and the upstream infrasonic wave generating device is controlled to emit infrasonic waves with a fixed frequency. The downstream infrasonic wave receiving device receives and collects the infrasonic waves transmitted through the gas pipeline and transmits the collected infrasonic waves to the computer. The computer filters the collected infrasonic waves to obtain Under normal working conditions, the attenuation diagram of the infrasonic amplitude without leakage;

[0072] (2) The computer controls the leakage valve to open to the preset caliber, controls the upstream infrasonic wave generating device to emit the same fixed frequency infrasonic wave as in step (1), and the downstream infrasonic wave receiv...

Embodiment 3

[0080] Embodiment 3: A gas pipeline leakage detection method based on infrasonic waves, using the gas pipeline leakage detection device based on infrasonic waves in Embodiment 1, the specific steps are as follows:

[0081] (1) The leakage valve of the computer is closed, and the upstream infrasonic wave generating device is controlled to emit infrasonic waves with a fixed frequency. The downstream infrasonic wave receiving device receives and collects the infrasonic waves transmitted through the gas pipeline and transmits the collected infrasonic waves to the computer. The computer filters the collected infrasonic waves to obtain Under normal working conditions, the attenuation diagram of the infrasonic amplitude without leakage;

[0082] The computer performs filtering processing on the collected infrasound wave, and the computer performs denoising processing on the infrasound wave signal. The denoising process is as follows:

[0083] 1) Perform preprocessing operations such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com