Preparation method of high-viscosity sliced paraffin

A production method and high-viscosity technology, applied in the field of biomedicine, can solve the problems of easy loose tablets, high scrap rate of slices, no way to increase the viscosity of paraffin wax, etc., and achieve the effect of good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

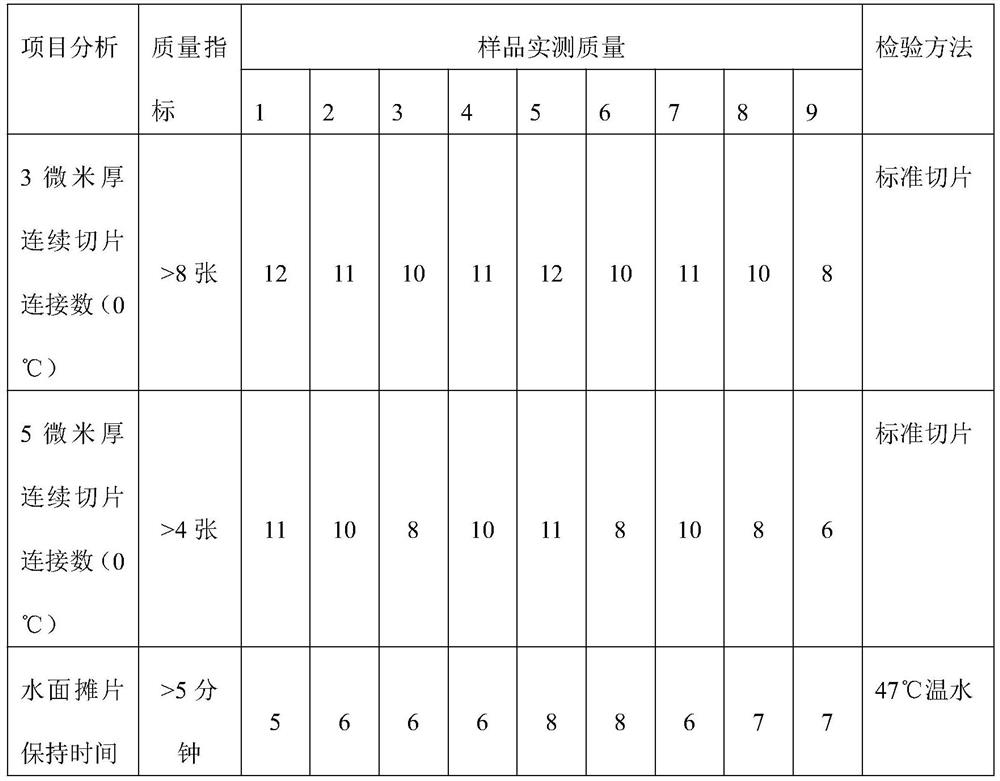

Examples

Embodiment 1

[0033] Get No. 58 fully refined paraffin wax of 750kg, add No. 70 microcrystalline wax of 100kg, obtain high-purity paraffin wax filtrate after mixing, emulsifying, precipitating, filtering through the aforementioned steps; Get No. 58 fully refined paraffin wax of 100kg, add 3kg of butyl rubber , 3g of antioxidant and 3g of activator were added to the filtrate after infrared high-temperature heating, and the temperature was lowered to 75°C for granulation and solidification to obtain high-viscosity sliced paraffin sample 1.

Embodiment 2

[0035] Get No. 58 fully refined paraffin wax of 750kg, add No. 70 microcrystalline wax of 150kg, obtain high-purity paraffin wax filtrate after mixing, emulsifying, precipitating, filtering through the aforementioned steps; Get No. 58 fully refined paraffin wax of 100kg, add 3kg of butyl rubber , 3g of antioxidant and 3g of activator were added to the filtrate after infrared high-temperature heating, and the temperature was lowered to 75°C for granulation and solidification to obtain high-viscosity section paraffin sample 2.

Embodiment 3

[0037] Get No. 58 fully refined paraffin wax of 750kg, add No. 70 microcrystalline wax of 200kg, obtain high-purity paraffin wax filtrate after mixing, emulsifying, precipitating, filtering through the aforementioned steps; Get No. 58 fully refined paraffin wax of 100kg, add 3kg of butyl rubber , 3g of antioxidant and 3g of activator were added to the filtrate after infrared high-temperature heating, and the temperature was lowered to 75°C for granulation and solidification to obtain high-viscosity sliced paraffin sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com