Preparation method of wear-resistant, high-viscosity and anti-corona paint

An anti-corona paint and high-viscosity technology, which is applied in the direction of fireproof coatings, coatings, epoxy resin coatings, etc., can solve the problems of low wear resistance, poor high temperature resistance, and easy peeling of the paint layer, so as to promote cohesion enhancement, Improve the bonding strength, the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

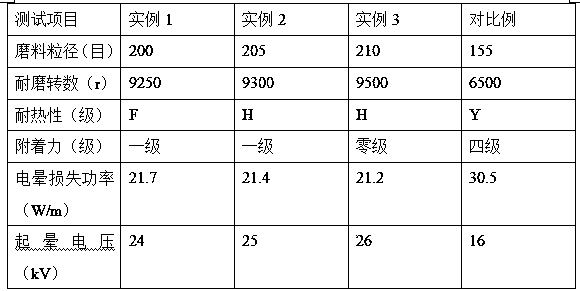

Examples

Embodiment Construction

[0024] Weigh the rice husks, clean them, and dry them. Mix the dried rice husks and biogas slurry at a mass ratio of 1:2 and spread them in ceramic tanks. Put the ceramic tanks open at a temperature of 28-35°C. In a greenhouse with a humidity of 60-70%, let it stand for 3-5 days for mildew treatment, seal the ceramic tank after the mold is over, and continue to stand for fermentation for 3-5 days; after the fermentation is completed, take out the fermentation product, filter and separate to obtain the fermentation filter residue, Put the obtained fermentation filter residue into a vacuum furnace, carbonize at a temperature of 200-400°C for 1-2 hours to obtain carbides, then mix carbides and sodium fluoride at a mass ratio of 50:1 and put them into a vacuum furnace. Under the protection of argon, the temperature was raised to 1100-1200°C, and the transformation was carried out for 3-4 hours, and the transformation was obtained; the transformation was transferred to a high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com