Novel p-type crystalline silicon cell emitter contact passivation preparation process

A technology of crystalline silicon cells and preparation process, which is applied in the direction of sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems such as bottlenecks in the improvement of conversion efficiency of PERC cells, and achieve reduction of recombination current, reduction of contact resistance, and improvement of conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

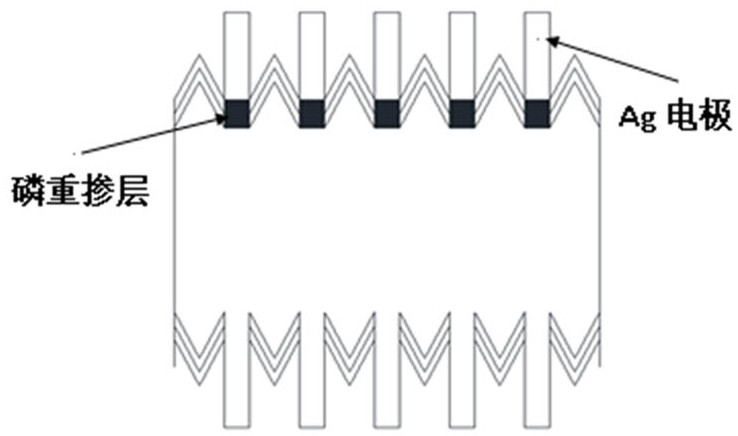

[0009] The present invention proposes a novel crystalline silicon battery emitter contact passivation preparation process, such as figure 1 , by preparing a phosphorus re-doped layer on the emitter, not only reduces the contact resistance of the metal region, but also passivates the emitter. Concrete preparation process is as follows:

[0010] 1. Clean the velvet. Alkali texturing is used for texturing, the etching amount is controlled at 0.4-0.6g, and the reflectivity is 7%-12%.

[0011] 2. Diffusion knots.

[0012] 3. Remove PSG and back etch. Clean the edge and back part of BSG, use alkali etching, control the etching amount at 0.14-0.17g, and reflectivity 35%-45%.

[0013] 4. High temperature oxidation.

[0014] 5. Front anti-reflection film. A silicon nitride film with a refractive index of 2.03-2.10 and a film thickness of 75-80nm is prepared in tubular PECVD.

[0015] 6. Back passivation and anti-reflection coating.

[0016] 7. Front laser groove. Green light w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com