dry toilet

A technology for toilets and dry toilets, which can be used in home appliances, sanitary equipment, applications, etc. It can solve the problems of easy accumulation of fermentation products and filling of fermentation tanks, slow fermentation speed of natural composting, incomplete fermentation of feces, etc., to reduce pollution and Spread of disease, compact structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

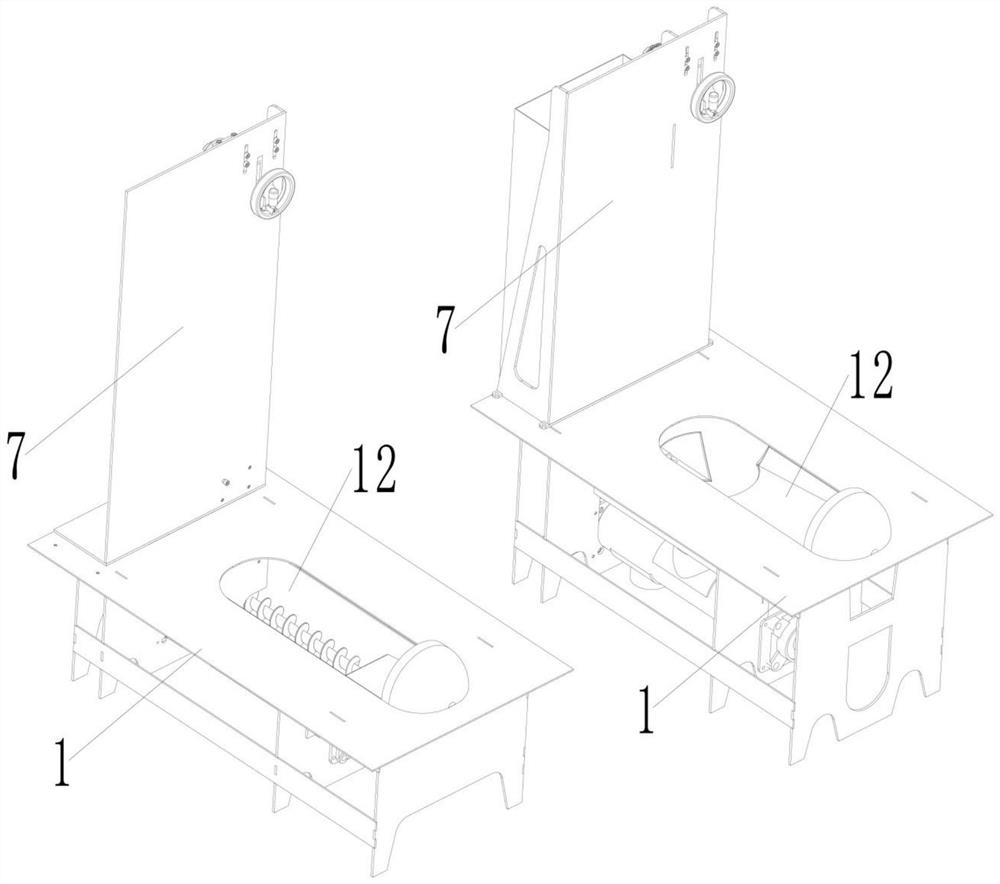

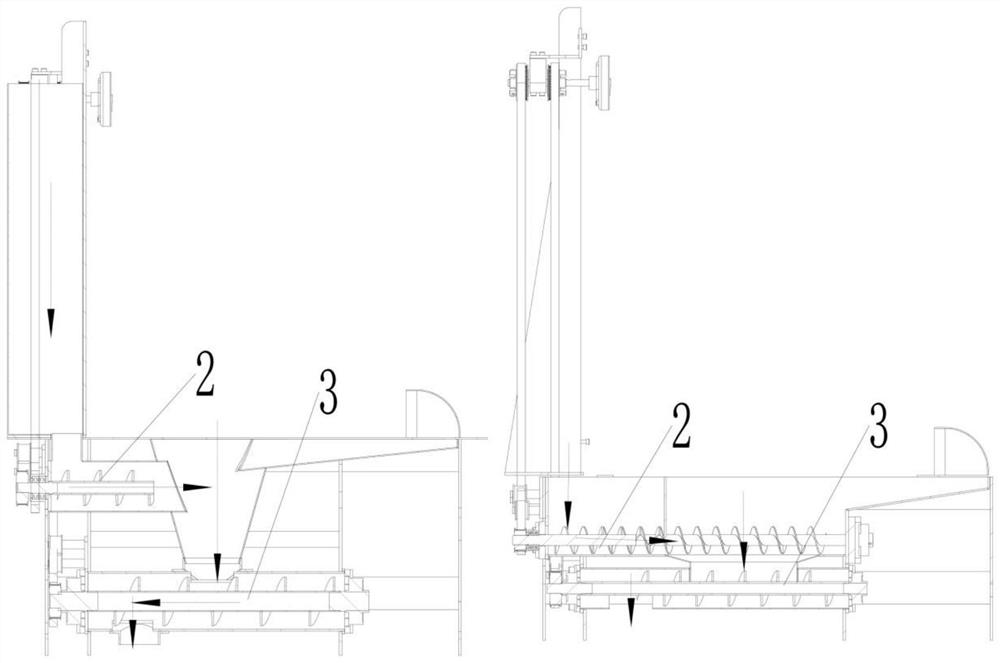

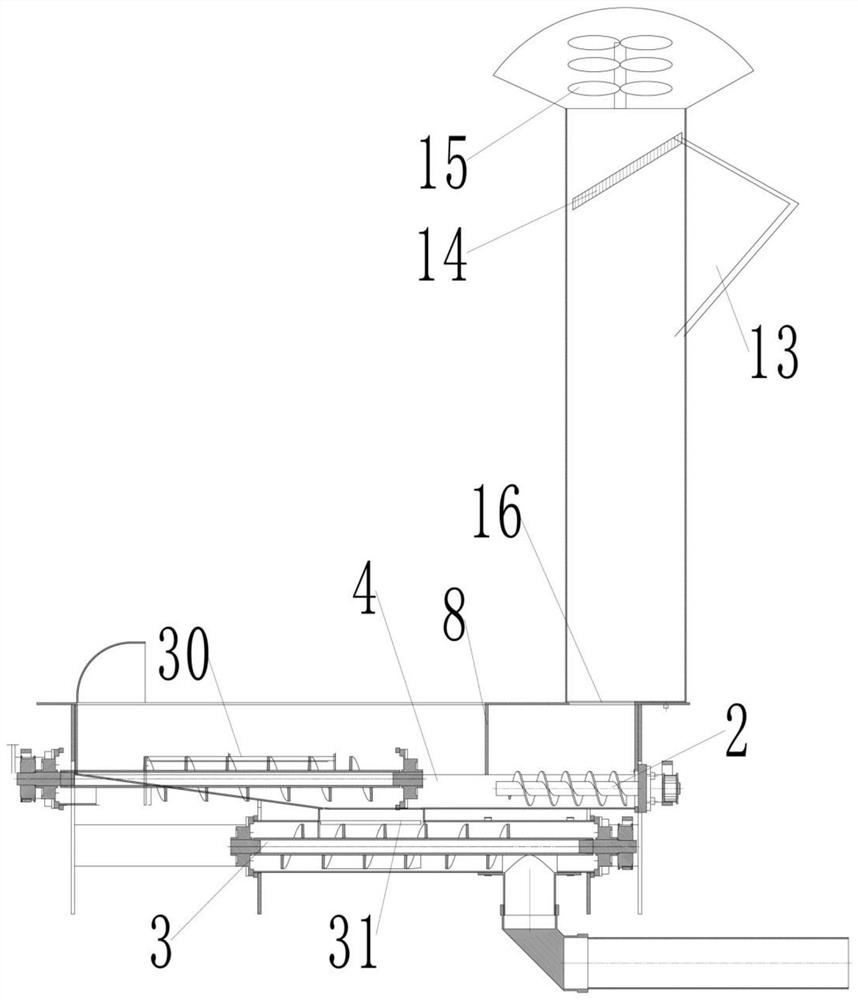

[0061] Such as Figure 1-10 Shown, the dry toilet closet of the present embodiment includes

[0062] The supporting frame 1, as a carrier, adopts a welding mechanism, including an upper platen 11 arranged on the ground;

[0063] The cushioning material buffer warehouse 7 is arranged on the rear side of the upper end of the upper platen 11, and the cushioning material is stored in advance;

[0064] The cushion material feeding screw part 2 is located under the upper platen 11 and the inlet is set at the outlet of the lower end of the cushion material buffer warehouse 7, which is used for horizontally pushing the cushion material;

[0065] The collection tank 4 is arranged on the dunnage feeding spiral part 2 to accept the dunnage output from the dunnage feeding spiral part 2;

[0066] The urinal 12 is arranged on the upper platen 11, and the lower end of the feeding slot 17 at the upper end of the middle part communicates with the collection tank bucket 4;

[0067] Material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com