Ammonia release adsorption device in the hydration reaction process of coal ash-based filling paste, adsorption method and detection method

A hydration reaction and adsorption device technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve problems such as residual ammonia escape, and achieve the effects of accurate detection, easy operation, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

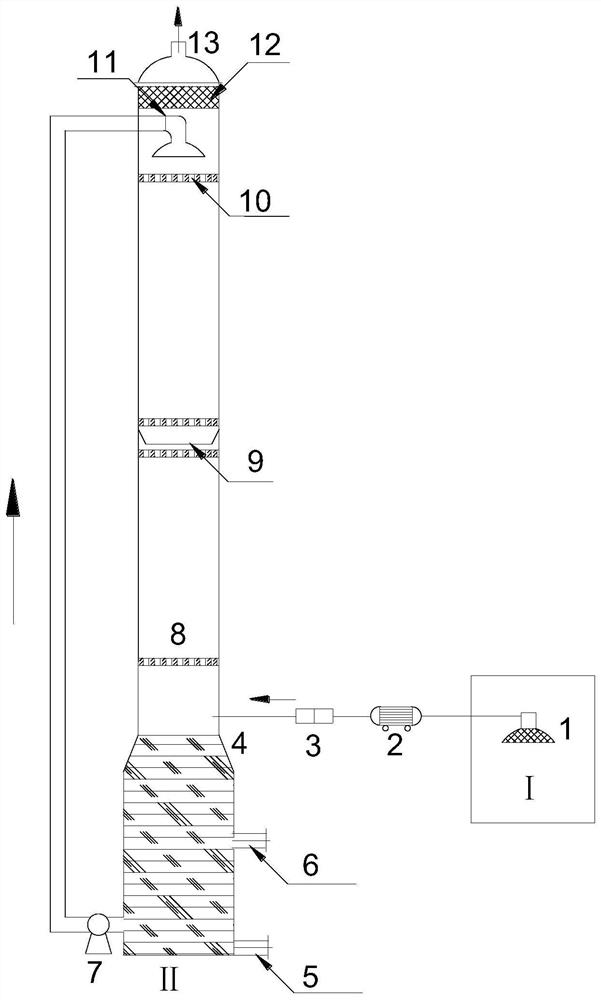

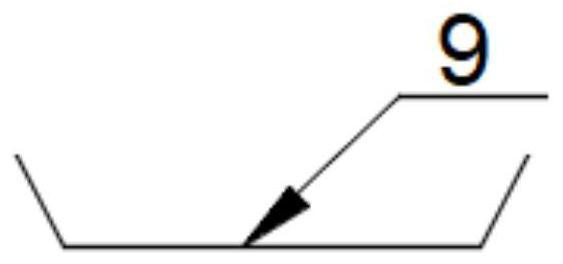

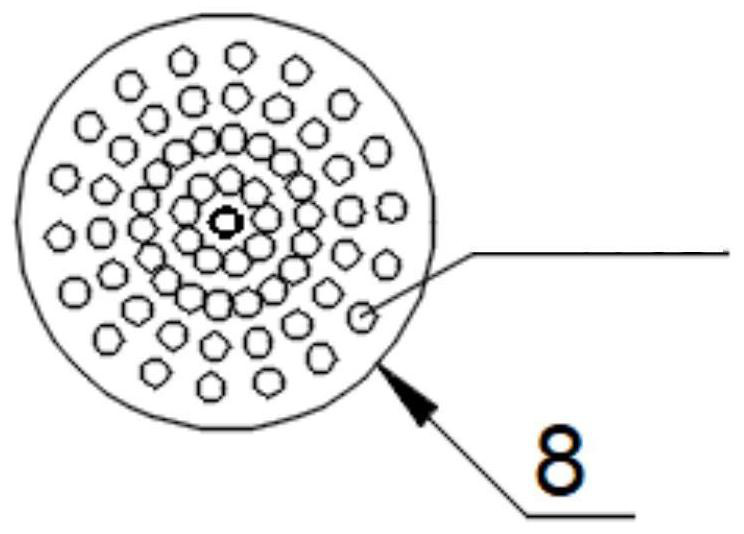

[0034] Such as figure 1 As shown, a fly ash-based filling paste hydration reaction process ammonia release adsorption device, the device is suitable for detection of denitrification fly ash-based filling mining paste in the maintenance process of simulated mine environment ammonia release , mainly including curing room I and ammonia adsorption tower II, and the fly ash-based filling paste is placed in curing room I. A gas collection hood 1 with a single outlet for air and gas is arranged above the curing room I, and the outlet is connected to the inlet 4 of the ammonia adsorption tower II through a pipeline with an air pump 2 and a gas flow meter 3 . In the ammonia adsorption tower II, the lower part of the gas inlet 4 is the bottom part of the tower, which stores the absorption liquid. The absorption liquid vent pipe 5 is arranged at the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com