Low-temperature plasma multi-processing-object experiment platform and processing method thereof

A technology of low-temperature plasma and experimental platform, which is applied in the field of plasma processing platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

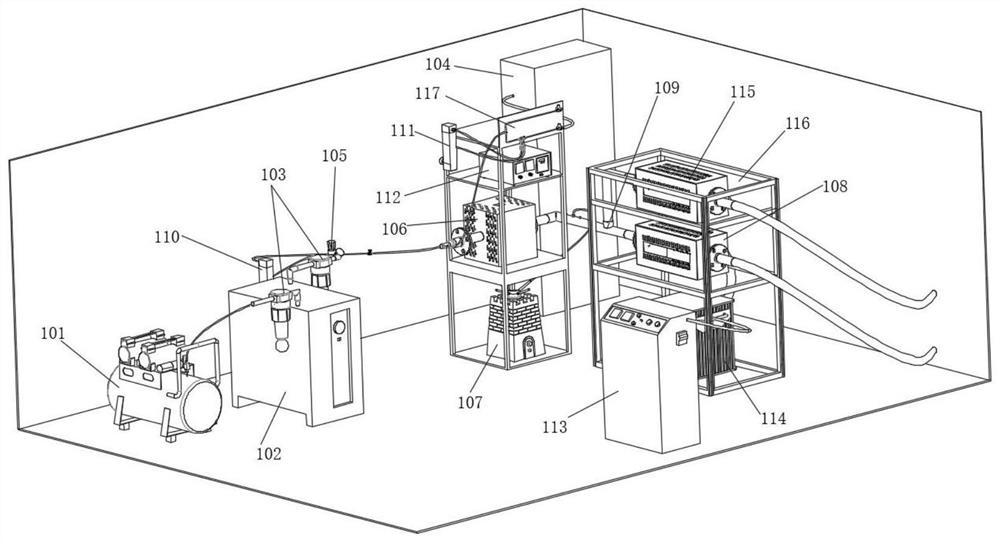

[0044] Embodiment 1: Low-temperature plasma multi-processing object experiment platform, such as figure 1 As shown, it includes an air compressor 101, a condensation dryer 102, a plurality of filters 103, an explosion-proof gas cylinder cabinet 104, a high pressure pressure reducing valve 105, a tube furnace 106, a humidifier 107, a gas treatment DBD reactor 108, and a plate DBD Reactor 115, high-voltage power supply 113 and step-up transformer 114, the specification of the air compressor 101 is 750*2-50L, voltage 220V, power 1500W, 4 cylinders, speed 1400r / min, production period volume 120L / min, The working pressure is 0.5-0.8MPa; the model of the condensation dryer 102 is 7.5AC, the specification is HF-1, the inlet pressure is ≤1.02Mpa, the type of refrigerant is R-12, the overall size is 700*400*595, and the gas handling capacity is 1.5m3 / min, supporting air compressor 101 power 1.5KW-7.5KW; the model of the filter 103 is 001-CAT, the inlet and outlet are 1 inch, the inlet...

Embodiment 2

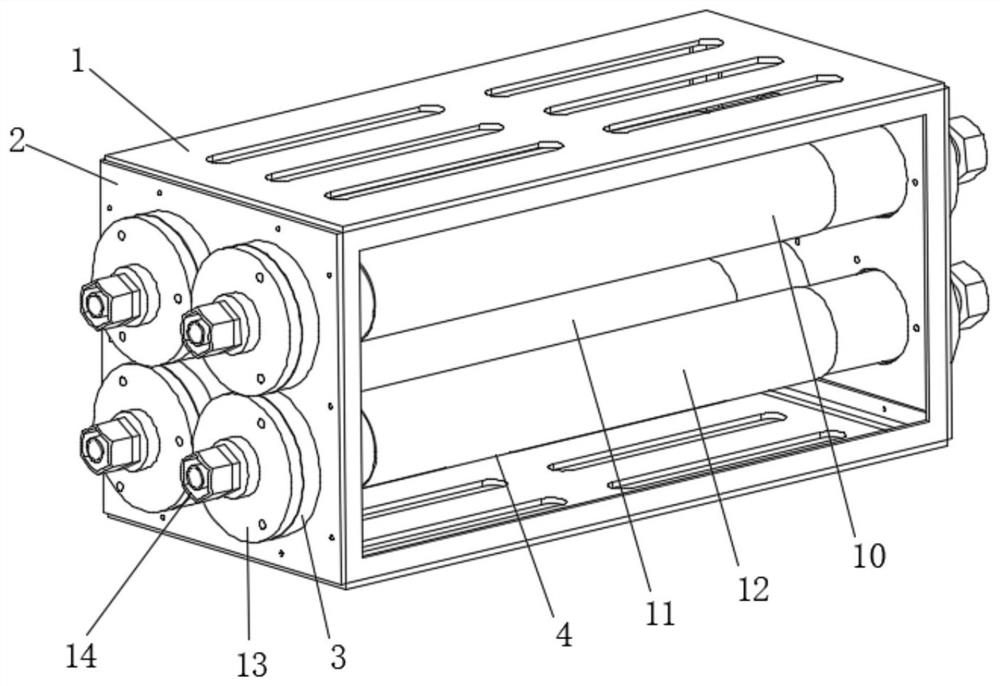

[0046] Embodiment 2: on the basis of embodiment 1, as Figure 3-4 As shown, including frame body 1, frame body 1 two ends are symmetrically provided with fixed plate 2, and described fixed plate 2 is provided with a plurality of fixed covers 3; Frame body 1 of the present invention, fixed plate 2, fixed cover 3 are all Metal material, a DBD single tube 4 is arranged between the fixed covers 3 corresponding to the two ends of the frame body 1, such as Figure 5As shown, the DBD single tube 4 includes a sleeve-shaped barrier medium layer 5 arranged between the fixed covers 3, the outer wall of the barrier medium layer 5 is sleeved with an external electrode 6, and the middle part of the barrier medium layer 5 is provided with The end is fixed on the inner electrode 7 on the fixed cover 3, and the gap between the inner electrode 7 and the barrier medium layer 5 forms a flow channel 8, and the gas in the flow channel 8 is purified under the negative ions generated by the blocking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com