A kind of non-fire concrete and preparation method thereof

A technology of concrete and refractory filler, which is applied in the field of non-fired concrete and its preparation, can solve the problems of internal structure damage of concrete, high temperature, and shorten the service life of non-fired concrete, so as to improve settlement resistance, prolong service life, and improve non-fire The effect of pyrophoric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

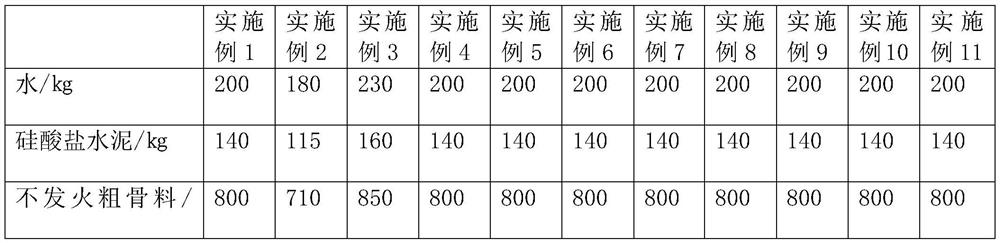

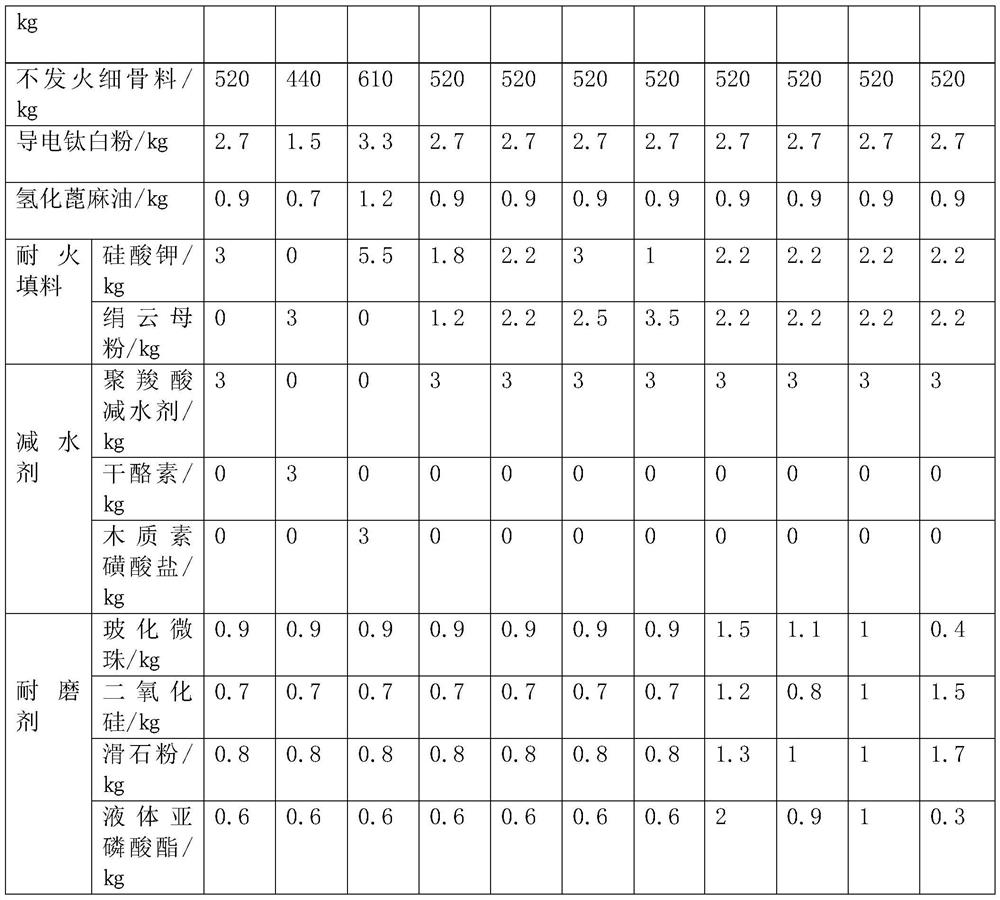

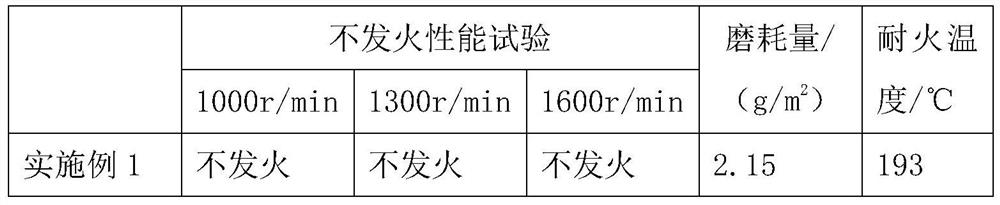

Embodiment 1

[0048] A kind of non-fire concrete, including the following components by weight: 200kg of water, 140kg of Portland cement, 800kg of dolomite-made crushed stone, 520kg of dolomite-made sand, 2.7kg of conductive titanium dioxide, and 0.9kg of hydrogenated castor oil ; The refractory filler is composed of potassium silicate 3kg, the water reducer is polycarboxylate water reducer 5kg, the wear agent is made of 90 mesh vitrified microbeads 0.9kg, silicon dioxide 0.7kg, talc powder 0.8kg and liquid sub Phosphate ester 0.6kg composition;

[0049] The preparation method of non-fire concrete comprises the following steps:

[0050] Step 1: Mix 200kg of water, 2.7kg of conductive titanium dioxide, 0.9kg of hydrogenated castor oil, and 3kg of potassium silicate, and stir at a speed of 850r / min for 35 minutes to form a suspension;

[0051]Step 2: the preparation method of wear-resisting agent, comprises the following steps:

[0052] Step 1: Mix evenly 0.9 kg of vitrified microbeads, 0.7...

Embodiment 12

[0060] The difference with Example 1 is that the preparation method of non-fired concrete comprises the following steps:

[0061] Step 1: Mix 200kg of water, 2.7kg of conductive titanium dioxide, 0.9kg of hydrogenated castor oil and 3kg of potassium silicate, and stir at a speed of 900r / min for 30 minutes to form a suspension;

[0062] Step 2: the preparation method of wear-resisting agent, comprises the following steps:

[0063] Step 1: Mix evenly 0.9 kg of vitrified microbeads, 0.7 kg of silicon dioxide, 0.8 kg of talc powder and 0.6 kg of liquid phosphite to obtain a mixture;

[0064] Step 2: Heat 0.6kg of liquid phosphite to 60°C and keep it warm. At a speed of 610r / min, add the mixture while stirring, and stir for 50 minutes to obtain an anti-wear agent.

[0065] Step 3: Add 140 kg of Portland cement, 800 kg of dolomite machine-made gravel, 520 kg of dolomite machine-made sand, 5 kg of polycarboxylate superplasticizer and the durable Abrasives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com