Pre-ash bucket sealing method

A technology of pre-ash barrels and sealing flanges is applied in the directions of engine sealing, chemical instruments and methods, chemical/physical/physical-chemical processes, etc. The effect of good sealing effect, simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

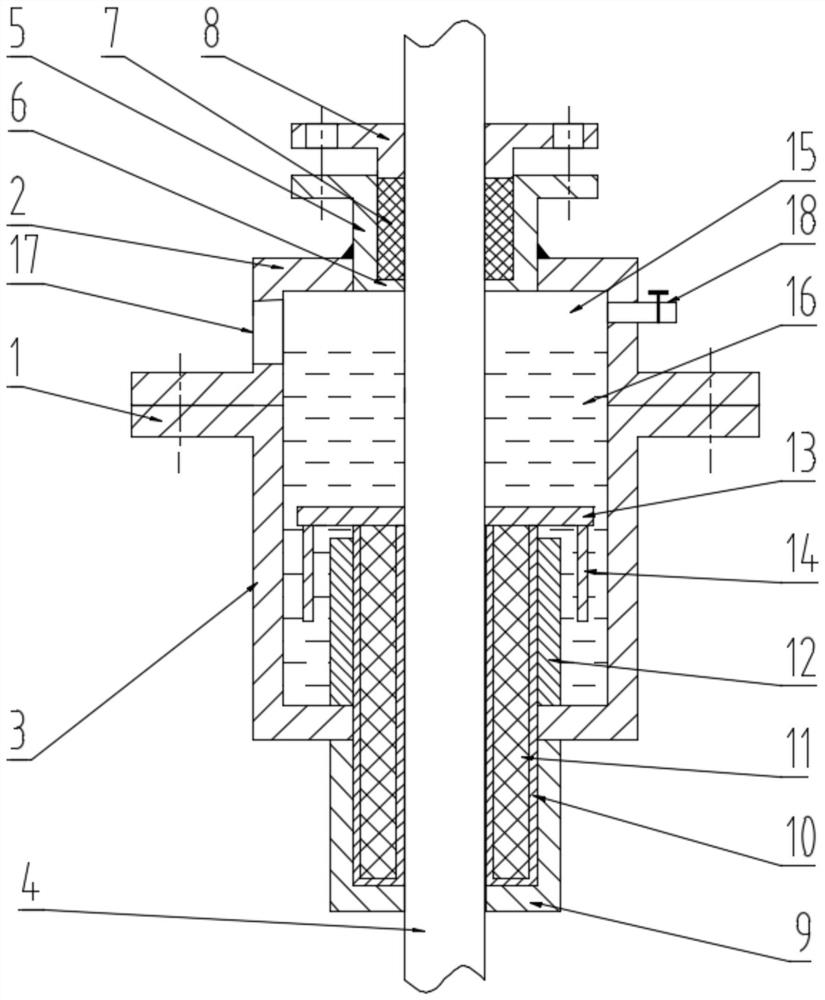

[0023] Embodiment 1, with reference to figure 1 , a method for sealing a pre-ash bucket, comprising a pre-ash bucket sealing device arranged on a cover of the pre-ash bucket, the sealing device of the pre-ash bucket includes a sealing flange 1 connected with the cover of the pre-ash bucket, and the sealing flange 1 is fixed with an upper sealing cylinder 2 and a lower sealing cylinder 3 respectively located on the top and bottom of the sealing flange 1, the upper sealing cylinder 2 is installed above the lid of the pre-ash bucket, and the lower sealing cylinder 3 extends into the pre-ash Inside the bucket; the stirring shaft 4 in the pre-ash bucket runs through the upper and lower sealing cylinders 3;

[0024] A stuffing box 5 is provided between the upper sealing cylinder 2 and the stirring shaft 4, and an annular upper sealing chamber is provided between the stuffing box 5 and the stirring shaft 4, and packing 7 is filled in the upper sealing chamber, and the stuffing box 5 ...

Embodiment 2

[0035] Example 2. In Example 1, the sealing liquid 16 is a mixed solution of butter and crushed fillers with a total mass of 4 kg, wherein the mass percentage of butter and crushed fillers is 2:1.

Embodiment 3

[0036] In Example 3, in Example 1, the sealing liquid 16 is a mixed solution of butter and crushed filler with a total mass of 5 kg, wherein the mass percentage of butter and crushed filler is 3:1.

[0037] The following are sealing performance comparison experiments and experimental data:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com