Novel tobacco product containing tobacco particles and manufacturing method thereof

A technology of tobacco products and tobacco particles, which is applied in the field of tobacco, can solve the problems of complex manufacturing process, low matching degree, and expensive equipment cost, and achieve the effects of prolonging storage time, simplifying the production process, and improving sensory experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

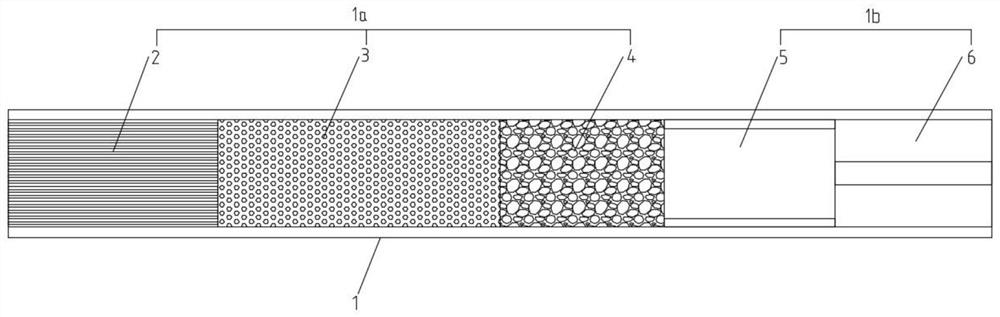

[0026] Reference attached figure 1 As shown, the present invention provides a novel tobacco product containing tobacco particles, comprising a tobacco paper tube 1, in which an aroma producing segment 2, a particle segment 3, a particle rod 4, an empty tube segment 5, The filter section 6, the aroma producing section 2, the granule section 3 and the granule rod 4 are compositely rolled into the first forming section 1a, and the empty pipe section 5 and the filtering section 6 are compositely rolled into the second forming section 1b, the first forming section 1a and the second forming section 1b are rubbed and formed.

[0027] Further, the aroma-producing section 2 is filled with orderly rolled recombined filamentous materials, and the recombined filamentous materials are rolled flakes, thick paddle flakes, papermaking flakes, dry flakes, and coating flakes The aroma-producing section 2 has played a blocking and aroma-producing function. Particle section 3 is loosely filled ...

Embodiment 2

[0034] On the basis of the above embodiments, the present invention also provides a method for making a novel tobacco product containing tobacco particles, comprising the following steps:

[0035] S1, granule pretreatment: according to every 100 parts of flavoring granules as a benchmark, add 5 parts of solidified liquid and 3 parts of PLA ultrafine powder to the flavoring granules, fully mix to obtain pretreatment granules, and the flavoring granules are cooling, The granule of fragrance-increasing compensation function selects tangerine peel for use in the present invention, and the composition of described solidification liquid is: the mixed solution of 1% adhesive, 0.1% weak acid, 95% water, and solidification liquid is in the mixing process, first in water once Add adhesive and weak acid, stir for 10 minutes and let it stand overnight. Further, the adhesive is sodium carboxymethyl cellulose, and the weak acid is phosphoric acid;

[0036] S2, filling: one end of the empty ...

Embodiment 3

[0040] On the basis of the above embodiments, another embodiment of the present invention is a method for making a novel tobacco product containing tobacco particles, comprising the following steps:

[0041]S1, particle pretreatment: according to every 100 parts of fragrance-enhancing granules as a benchmark, add 8 parts of solidified liquid and 6 parts of PLA superfine powder to the fragrance-enhancing granules, fully mix to obtain pretreatment granules, and the fragrance-enhancing particles are cooling, The granule of fragrance-increasing compensation function selects tangerine peel for use in the present invention, and the composition of described solidification liquid is: the mixed solution of 2% adhesive, 0.5% weak acid, 97.5% water, and solidification liquid is in the mixing process, first in water once Add adhesive and weak acid, stir for 20 minutes and let it stand overnight. Further, the adhesive is sodium carboxymethyl cellulose, and the weak acid is phosphoric acid; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com