Method for producing silane modified polyurethane sealant by using secondary amino alpha-silane

A technology of polyurethane sealant and silane modification, applied in the directions of polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve the problem of slow curing speed of silane-modified polyurethane sealants and hydrolysis of silane-terminated prepolymers Problems such as low reactivity and difficulty in capping end-capped silanes to achieve the effect of fast curing speed, simple end-capping and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

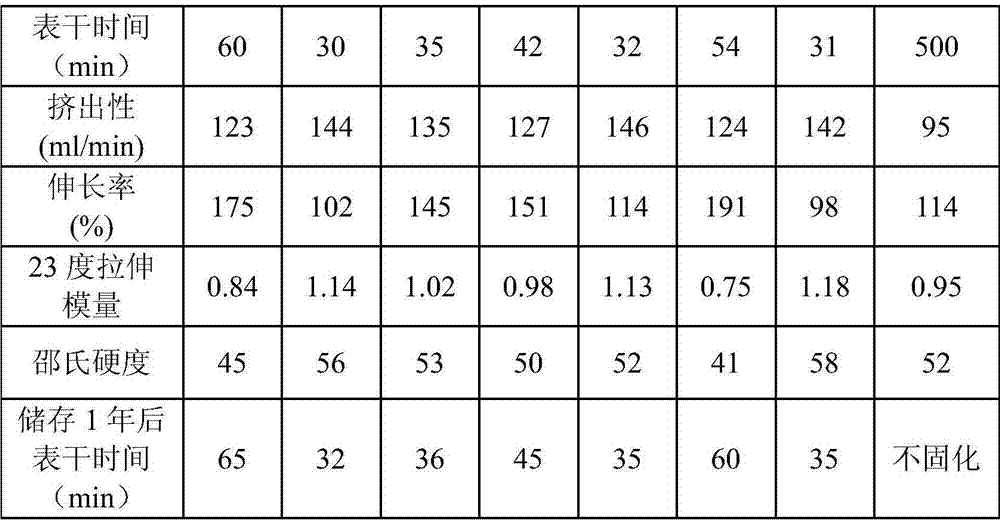

Examples

Embodiment 1

[0045] Put 1500kg of polyoxypropylene glycol with a molecular weight of 8000 into a 2000kg dehydration kettle, dehydrate for 120min at a temperature of 115°C and a negative pressure of -0.08MPa, and detect that the moisture in the polyoxypropylene glycol is 150ppm.

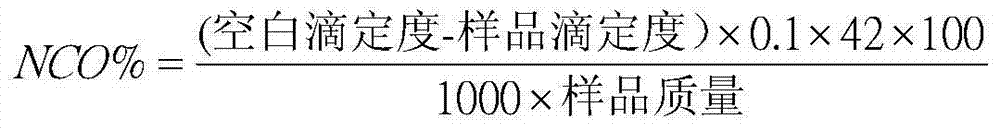

[0046] Pour the dehydrated polyoxypropylene diol into the reactor and cool it down to 60°C, add 41kg of 1,6 hexamethylene diisocyanate and 1kg of dibutyltin dilaurate catalyst into the reactor, at a pressure of -0.08MPa~- Stir polyoxypropylene diol, 1,6 hexamethylene diisocyanate and dibutyltin dilaurate at 0.09MPa and 60°C for 120 minutes to form a polyurethane prepolymer, which is obtained by chemical titration of NCO value The NCO value of the polyurethane prepolymer is 1.2.

[0047] Add 35kg of anilinomethyltriethoxysilane to the reaction kettle, and under the condition of pressure of -0.08MPa~-0.09MPa and temperature of 80°C, anilinomethyltriethoxysilane and polyurethane in the reaction kettle The prepolymer...

Embodiment 2

[0051] Put 1300kg of polyoxypropylene diol with a molecular weight of 8000 and 200kg of polyoxypropylene triol with a molecular weight of 5500 into a 2000kg dehydration kettle, dehydrate for 180min at a temperature of 110°C and a negative pressure of -0.09MPa, and detect the polyoxypropylene diol The moisture in the alcohol and polyoxypropylene triol was 160 ppm.

[0052] Pour the dehydrated polyoxypropylene diol and polyoxypropylene triol into the reactor and cool to 70°C, add 55kg of 1,6 hexamethylene diisocyanate and 1kg of dibutyltin dilaurate into the reactor. 0.08MPa~-0.09MPa, at a temperature of 80°C, stir polyoxypropylene diol, polyoxypropylene triol, hexamethylene diisocyanate and dibutyltin dilaurate for 180 minutes to form a polyurethane prepolymer. The chemical titration method of NCO value obtained the NCO value of polyurethane prepolymer as 1.

[0053] Add 48kg of anilinomethyltriethoxysilane to the reaction kettle, and under the condition of pressure of -0.08MP...

Embodiment 3

[0057] Put 1000kg of polyoxypropylene diol with a molecular weight of 2000 and 500kg of polyoxypropylene triol with a molecular weight of 4000 into a 2000kg dehydration kettle, dehydrate for 150min at a temperature of 120°C and a negative pressure of -0.0085MPa, and detect the polyoxypropylene diol The moisture in the alcohol and polyoxypropylene triol was 155 ppm.

[0058] Pour the dehydrated polyoxypropylene diol and polyoxypropylene triol into the reactor and cool it to 65°C, add 283kg of isophorone diisocyanate and 1kg of dibutyltin dilaurate into the reactor at a pressure of -0.08MPa ~-0.09MPa, under the condition of temperature of 65℃, stir polyoxypropylene diol, polyoxypropylene triol, isophorone diisocyanate and dibutyltin dilaurate for 150min to form polyurethane prepolymer, adopt NCO value The NCO value of the polyurethane prepolymer is 2 by the chemical titration method.

[0059] Add 200kg of carbamic acid methylmethyldimethoxysilane to the reaction kettle, and und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com