Welding head for deep hole surfacing

A welding head and deep hole technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of inconvenient moving and lifting, occupying a large space, etc., and achieve the effect of easy moving and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technology of the present invention will be further specifically described below in conjunction with the accompanying drawings.

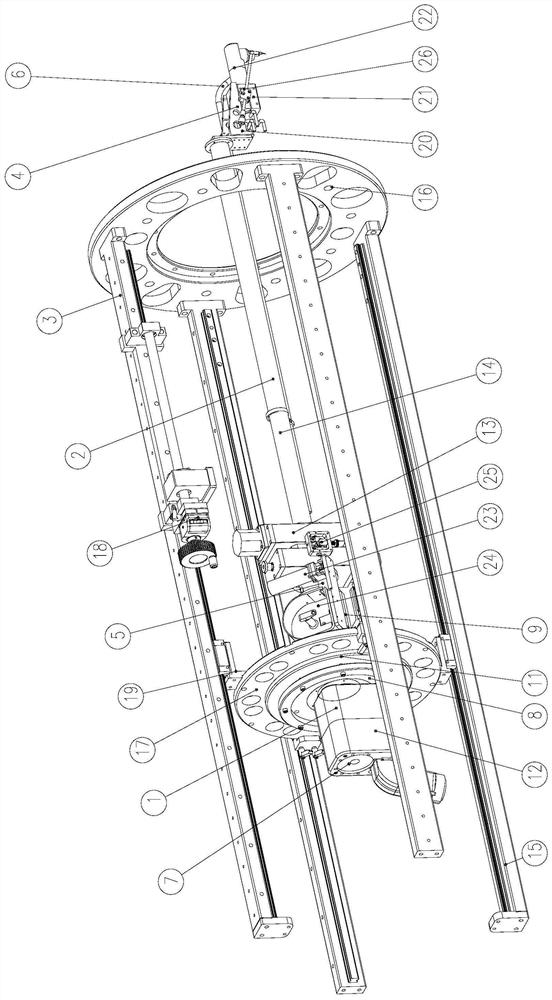

[0026] Such as figure 1 As shown, a welding head for deep hole surfacing mainly includes six parts structure, the whole head is supported and positioned by the fixed adjustment device 3, the wireless rotary device 1 is fixed on the fixed adjustment device 3, and the elongation The arm assembly 2 is fixed on the wireless rotary device 1, the end of the extension arm assembly 2 is fixed with the welding torch assembly 4, the wire feeding mechanism 5 is fixed on the wireless rotary device 1, and the welding wire is delivered to the welding torch position of the welding torch assembly 4, and the welding torch An imaging device 6 is also installed on the assembly 4 .

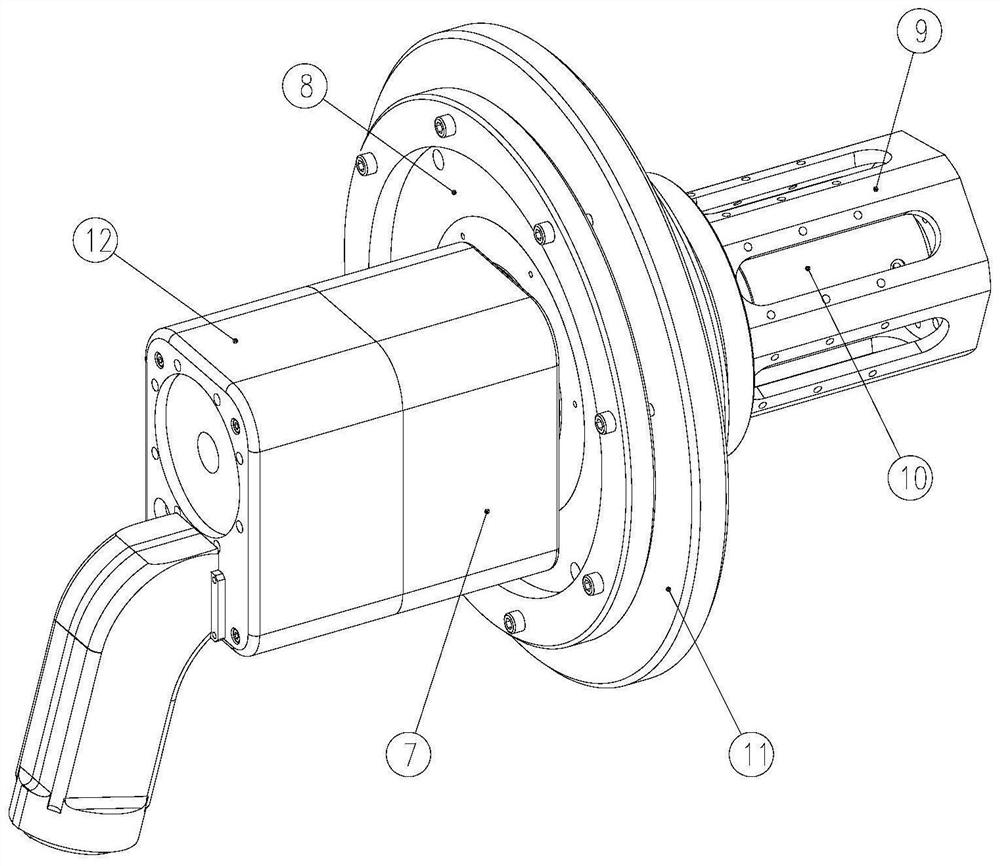

[0027] Such as figure 2 As shown, the wireless rotary device 1 includes a rotary drive assembly 7, a fixed insulating base 8, a rotary support mechanism 9, a conductive slip ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap