Numerically-controlled milling-grinding integrated machine

A CNC milling and all-in-one machine technology, which is applied to metal processing machinery parts, other manufacturing equipment/tools, maintenance and safety accessories, etc., can solve problems such as time-consuming and labor-intensive, dirt accumulated at the nozzle port of the coolant nozzle, nozzle blocked, etc., to achieve Easy to use, prevent nozzle clogging, and liberate manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

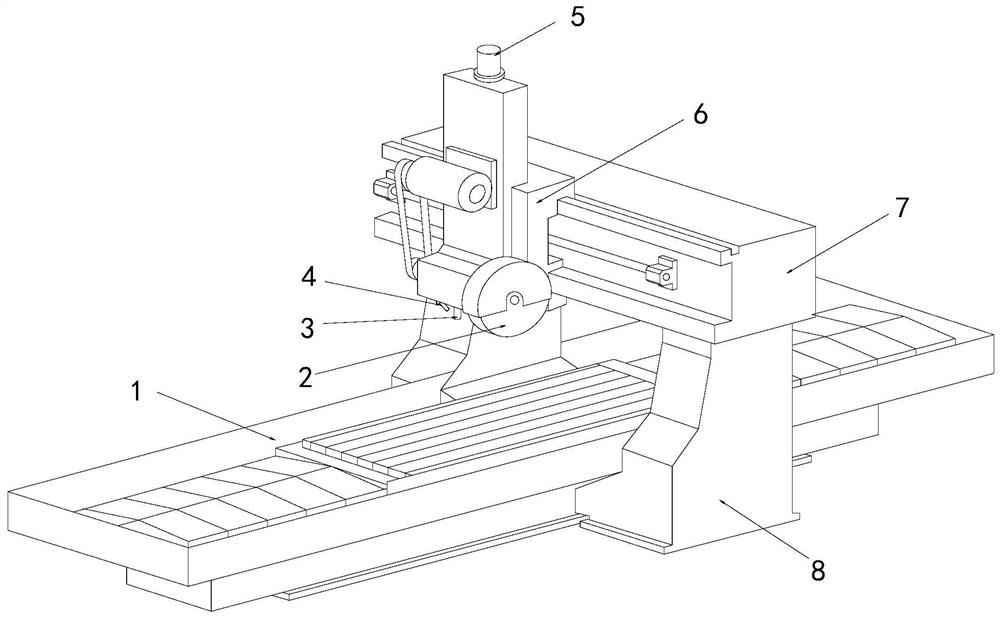

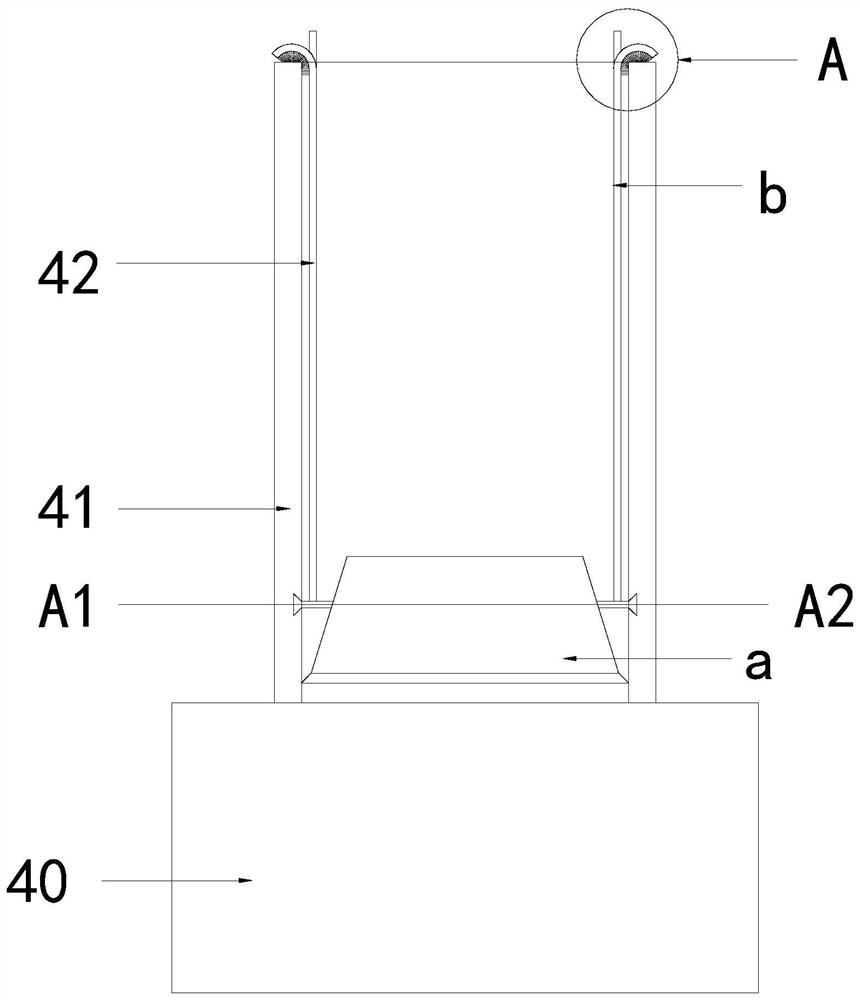

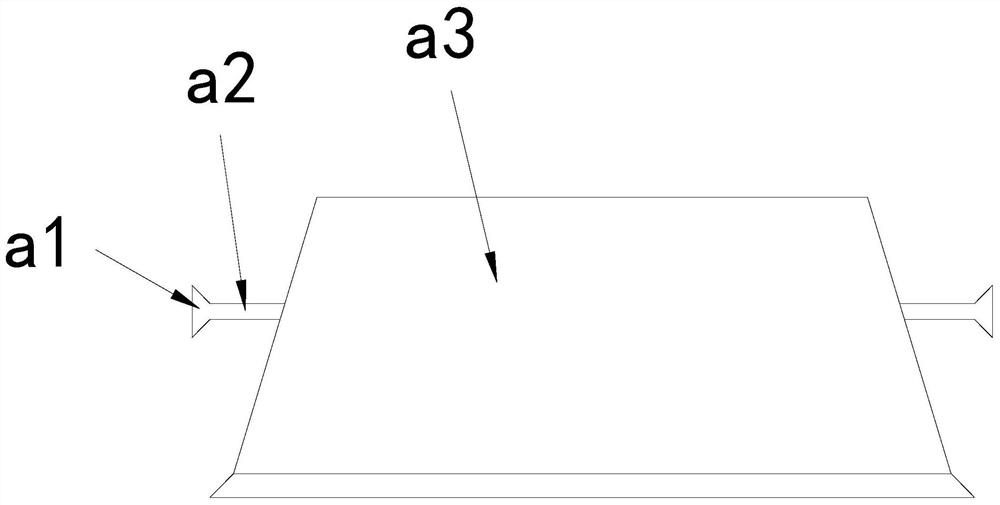

[0031] see Figure 1-7 , the present invention provides a technical solution for a CNC milling and grinding machine: its structure includes a workbench 1, a grinding wheel 2, a drill bit 3, a nozzle 4, a cylinder 5, a moving frame 6, a horizontal slide rail 7, and a support 8. The workbench The two sides of 1 are respectively connected with supports 8, the horizontal slide rail 7 is arranged on the top of the workbench 1 and both ends are respectively connected with the supports 8, the mobile frame 6 is installed on the side of the horizontal slide rail 7, and the mobile frame 6 is provided with a cylinder 5 at the top, and the moving frame 6 is equipped with a drill bit 3 and a grinding wheel 2 respectively. The side of the drill bit 3 is provided with a nozzle 4, and the nozzle 4 is installed at the bottom of the moving frame 6. The nozzle 4 includes a water valve 40 , the water outlet pipe 41, the anti-blocking structure 42, the water valve 40 is connected with the water ou...

Embodiment 2

[0034] see Figure 1-8 , the present invention provides a technical solution for a CNC milling and grinding machine: its structure includes a workbench 1, a grinding wheel 2, a drill bit 3, a nozzle 4, a cylinder 5, a moving frame 6, a horizontal slide rail 7, and a support 8. The workbench The two sides of 1 are respectively connected with supports 8, the horizontal slide rail 7 is arranged on the top of the workbench 1 and both ends are respectively connected with the supports 8, the mobile frame 6 is installed on the side of the horizontal slide rail 7, and the mobile frame 6 is provided with a cylinder 5 at the top, and the moving frame 6 is equipped with a drill bit 3 and a grinding wheel 2 respectively. The side of the drill bit 3 is provided with a nozzle 4, and the nozzle 4 is installed at the bottom of the moving frame 6. The nozzle 4 includes a water valve 40 , the water outlet pipe 41, the anti-blocking structure 42, the water valve 40 is connected with the water ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com