Preparation method of sugarcane sugar-increasing agent

A sugar-enhancing agent and sugarcane technology, applied in botany equipment and methods, biocides, animal repellants, etc., can solve the problems of increased soil viscosity, difficulty, and high cost, and achieve easy absorption and utilization of crops, good sequestration synthesizing ability and the effect of promoting fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

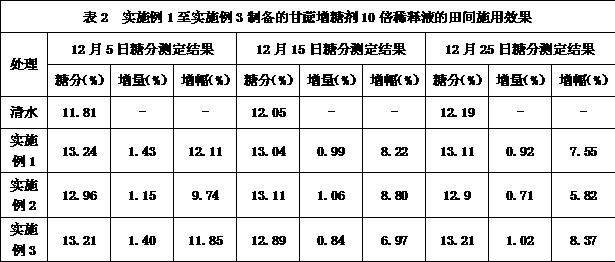

Examples

Embodiment 1

[0026] A preparation method of sugarcane sugar enhancer, which comprises the following steps.

[0027] Step 1: Take 100L of molasses alcohol raffinate, add 0.5 kg of polyacrylamide to the molasses alcohol raffinate, put it into a sedimentation tank, and let it settle in the sedimentation tank for 5-10 hours to obtain a supernatant.

[0028] Step 2, take the supernatant of step 1 and add 10 kg of molasses, 0.2 L of Bacillus subtilis seed solution, 0.2 L of Bacillus megaterium seed solution, 0.3 L of Aspergillus niger seed solution and 0.4 L of silicone defoamer, mix well Adding a pH adjuster to adjust the pH to 7.0-7.3 to obtain a mixed solution;

[0029] The bacteria content in the Bacillus subtilis seed liquid, Bacillus megaterium seed liquid and Aspergillus niger seed liquid>1×10 8 CFU / mL; the solid content of the organosilicon defoamer is 30%, which contains methyl silicone oil, sodium tripolyphosphate, sodium chloride, mannitol and silicon dioxide; the pH regulator is se...

Embodiment 2

[0034] A preparation method of sugarcane sugar enhancer, which comprises the following steps.

[0035] Step 1: Take 100 L of molasses alcohol raffinate, add 0.45 kg of polyacrylamide to the molasses alcohol raffinate, put it into the sedimentation tank, and let it settle in the sedimentation tank for 5-10 hours to obtain the supernatant.

[0036] Step 2, take the supernatant of step 1 and add 8 kg of molasses, 0.3 L of Bacillus subtilis seed solution, 0.3 L of Bacillus megaterium seed solution, 0.2 L of Aspergillus niger seed solution and 0.45 L of silicone defoamer, mix well Adding a pH adjuster to adjust the pH to 7.0-7.3 to obtain a mixed solution;

[0037] The bacteria content in the Bacillus subtilis seed liquid, Bacillus megaterium seed liquid and Aspergillus niger seed liquid>1×10 8 CFU / mL; the solid content of the organosilicon defoamer is 30%, which contains methyl silicone oil, sodium tripolyphosphate, sodium chloride, mannitol and silicon dioxide; the pH regulator...

Embodiment 3

[0042] A preparation method of sugarcane sugar enhancer, which comprises the following steps.

[0043] Step 1: Take 100 L of molasses alcohol raffinate, add 0.4 kg of polyacrylamide to the molasses alcohol raffinate, put it into the sedimentation tank, and let it settle in the sedimentation tank for 5-10 hours to obtain the supernatant.

[0044] Step 2, take the supernatant of step 1 and add 5 kg of molasses, 0.2 L of Bacillus subtilis seed solution, 0.3 L of Bacillus megaterium seed solution, 0.3 L of Aspergillus niger seed solution and 0.5 L of silicone defoamer, mix well Adding a pH adjuster to adjust the pH to 7.0-7.3 to obtain a mixed solution;

[0045] The bacteria content in the Bacillus subtilis seed liquid, Bacillus megaterium seed liquid and Aspergillus niger seed liquid>1×10 8 CFU / mL; the solid content of the organosilicon defoamer is 30%, which contains methyl silicone oil, sodium tripolyphosphate, sodium chloride, mannitol and silicon dioxide; the pH regulator i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com