Lead-acid battery electrolyte extraction device

An extraction device and lead-acid battery technology, applied in sampling devices, measuring devices, sampling, etc., can solve the problems of poor extraction efficiency and effect, not suitable for electrolyte extraction, and electrolyte extraction, etc., to achieve novel design and practicability Strong, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

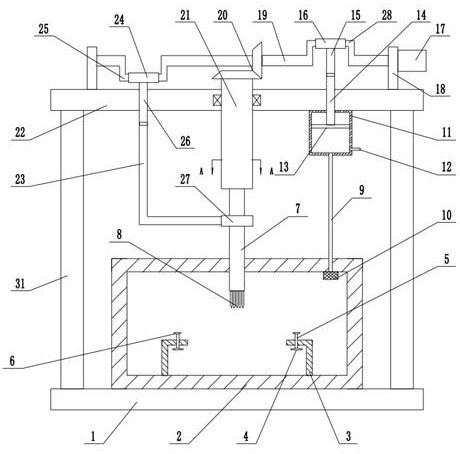

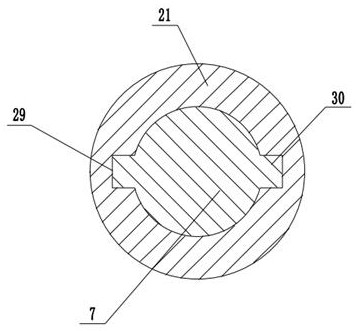

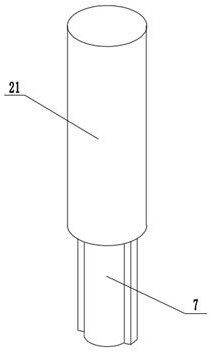

[0028] refer to Figure 1~3 , in the embodiment of the present invention, a lead-acid battery electrolyte extracting device comprises a fixed base plate 1, an extraction box 2 is installed in the middle of the upper end of the fixed base plate 1, and an airtight door is connected to the outside of the extraction box 2 through a hinge, thereby realizing the The sealing effect inside the extraction box 2, the bottom end of the extraction box 2 is equipped with a positioning frame 3, the positioning frame 3 is an L-shaped structure, and a positioning column 5 is installed in the middle of the upper end of the positioning frame 3, and the positioning column 5 is a threaded rod structure , the positioning plate 4 is installed at the bottom of the positioning column 5, and the positioning handle 6 is installed at the top of the positioning column 5. By rotating the positioning handle 6, the positioning column 5 moves up and down, and then the fixing effect of the battery pack to be e...

Embodiment 2

[0030]In another embodiment of the present invention, a lead-acid battery electrolyte extracting device includes a fixed bottom plate 1, an extraction box 2 is installed in the middle of the upper end of the fixed bottom plate 1, and an airtight door is connected to the outside of the extraction box 2 through a hinge. A positioning frame 3 is installed at the inner bottom of the extraction box 2, and the positioning frame 3 is an L-shaped structure, and a positioning column 5 is installed in the middle of the upper end of the positioning frame 3, and the positioning column 5 is a threaded rod structure, and a positioning plate is installed at the bottom of the positioning column 5 4. A positioning handle 6 is installed on the top of the positioning column 5, a support frame is installed on both sides of the upper end of the fixed base plate 1, a support plate 22 is installed on the top of the support frame, and the middle part of the upper end of the support plate 22 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com