Efficient wastewater treatment device

A high-efficiency technology for wastewater treatment, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve problems such as adsorption and filtration of difficult wastewater, achieve efficient cleaning and improve treatment efficiency , the effect of promoting fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

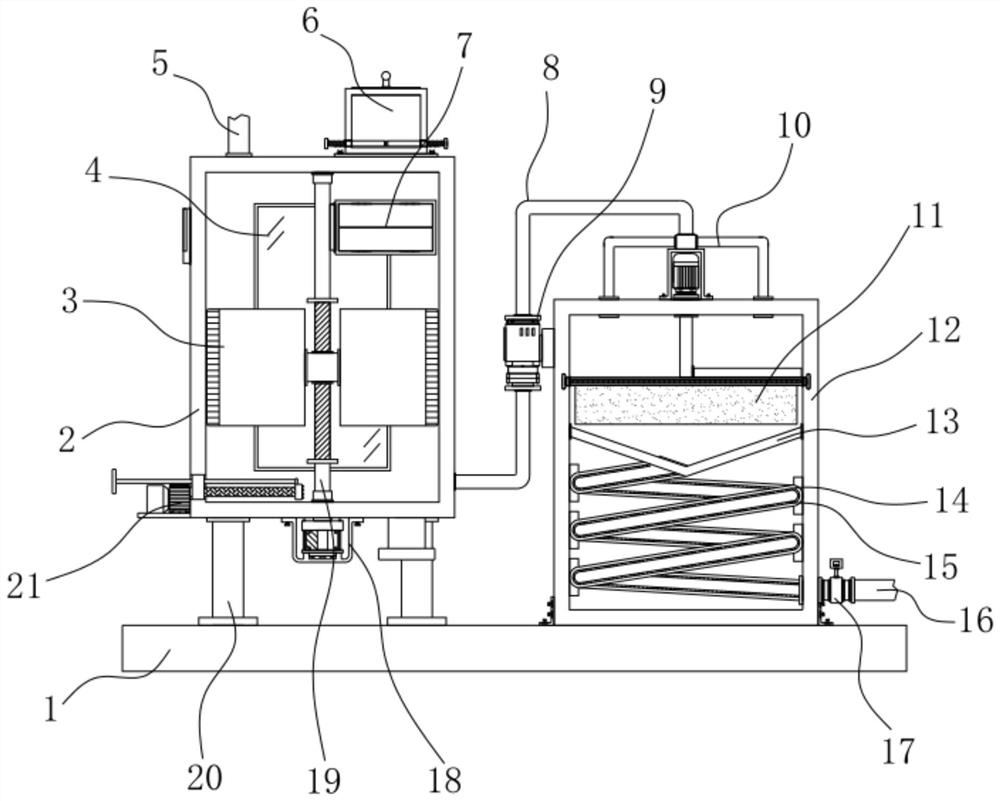

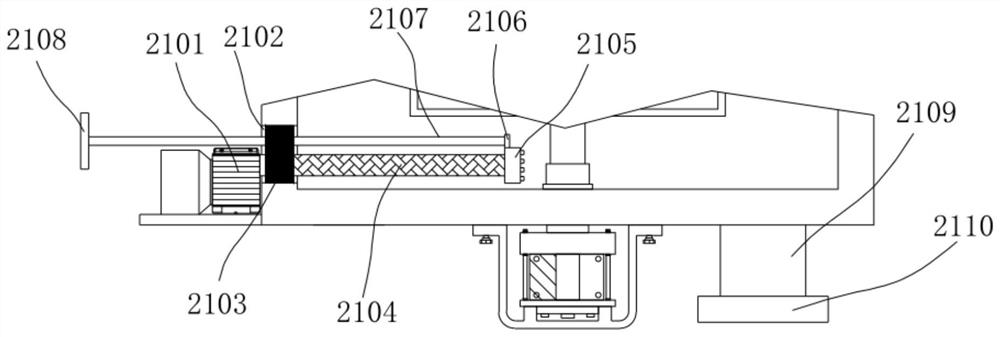

[0038] Example 1: See Figure 1-7 , a high-efficiency wastewater treatment device, including a base 1, a first housing 2, a connecting pipe 8 and a second housing 12, four corners on one side of the top of the base 1 are fixedly connected with pillars 20, and the top of the pillars 20 The first casing 2 is fixedly connected between them, and the bottom end outside the first casing 2 is fixedly connected with a variable frequency motor 18. Rod 19, the bottom end on the transmission rod 19 is movably connected with a cleaning mechanism 3, and the top end on the transmission rod 19 is movably connected with a collection mechanism 7, and the inside of both ends of the first housing 2 is fixedly connected with a glass plate 4, the first housing 2 One side of the top is fixedly connected with the water inlet pipe 5, the other side of the top of the first casing 2 is fixedly connected with the feeding structure 6, the bottom inside the first casing 2 is movably connected with the dre...

Embodiment 2

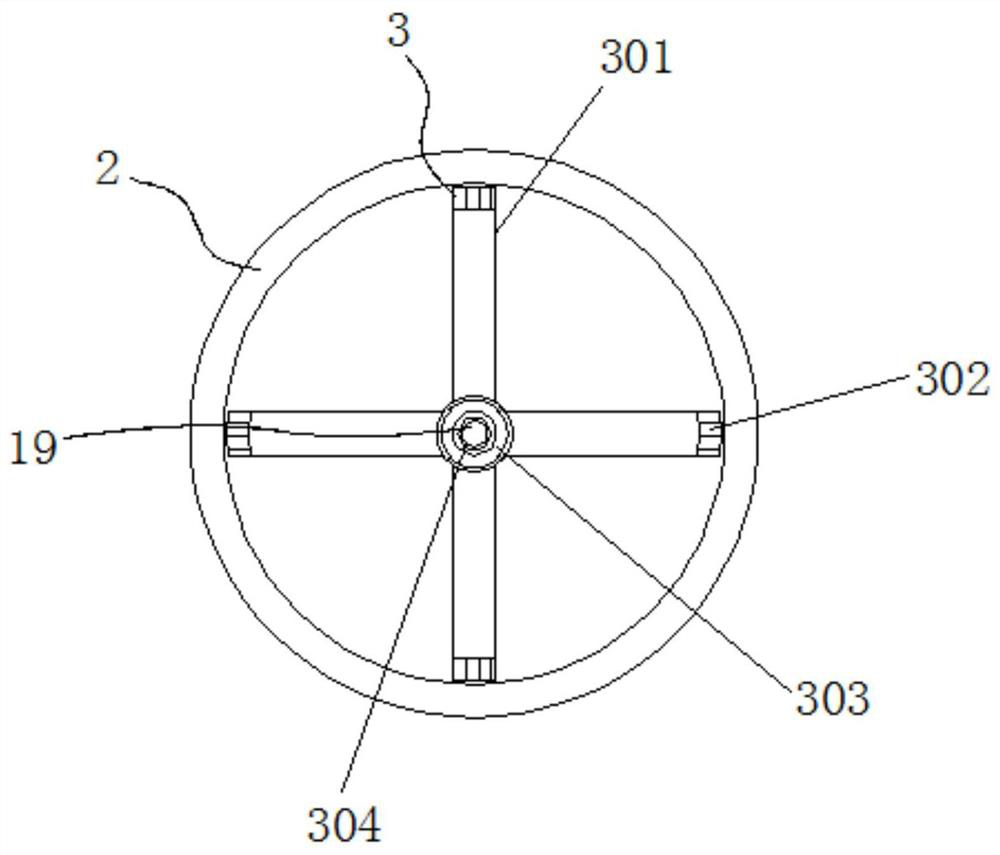

[0041] Embodiment 2: cleaning mechanism 3 is made up of rotating blade 301, steel brush 302, lifting block 303 and thread 304, and thread 304 is evenly arranged on the bottom end on the transmission rod 19, and the outside of transmission rod 19 bottom end is provided with lifting block 303, And the rotating blade 301 is evenly and fixedly connected to the lifting block 303, and the steel brush 302 is fixedly connected to one side of the rotating blade 301, and the lifting block 303 and the rotating blade 301 are all on the same vertical plane;

[0042] Specifically, such as figure 1 and image 3 As shown, start the frequency conversion motor 18 to rotate the transmission rod 19, so that the lifting block 303 performs lifting movement under the nesting of the screw thread 304, and the rotating blade 301 whose surface is evenly fixed can promote the separation of the medicament and the waste water inside the first housing 2. Fusion, at the same time the steel brush 302 that sp...

Embodiment 3

[0043] Embodiment 3: The feeding structure 6 is composed of a storage box 601, a pull rod 602, a return spring 603, a limit plate 604, a movable groove 605 and a top cover 606. The storage box 601 is fixedly connected to a top of the first housing 2. side, the inside of the top of the storage box 601 is provided with a top cover 606, the inside of the bottom of both sides of the storage box 601 is provided with a movable groove 605, and the inside of the movable groove 605 is all provided with a limiting plate 604, and one side of the limiting plate 604 Both ends of each are fixedly connected with a pull rod 602, and a return spring 603 is fixedly connected between the pull rod 602 and one side of the material storage box 601;

[0044] The limiting plates 604 are all on the same horizontal plane, and the return springs 603 and the movable grooves 605 are arranged in concentric circles;

[0045] Specifically, such as figure 1 and Figure 4 As shown, open the top cover 606 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com