Low-gloss PC material and preparation method thereof

A low-gloss, formula technology, used in the chemical industry, can solve the problems of PC material toughness decline, affecting PC material performance, etc., and achieve the effects of good toughness, good matte surface effect, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

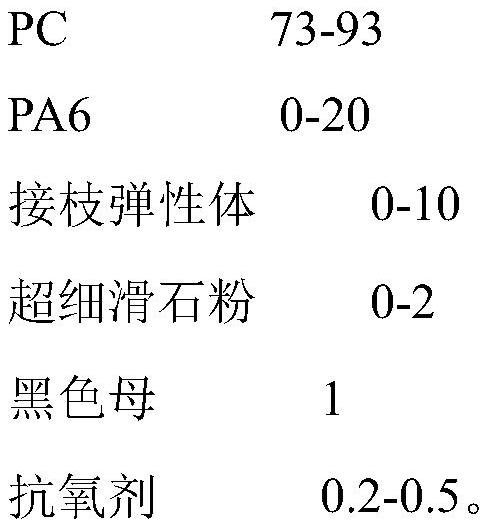

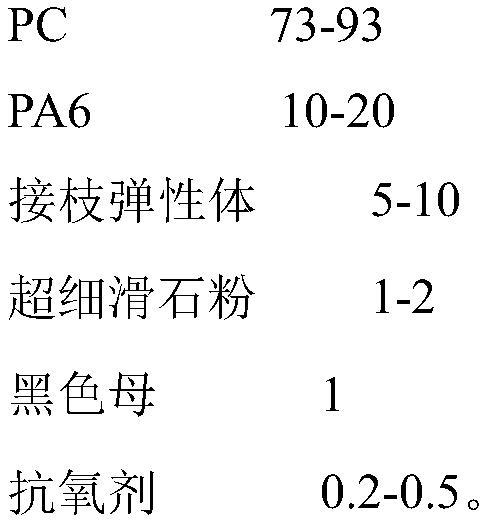

Method used

Image

Examples

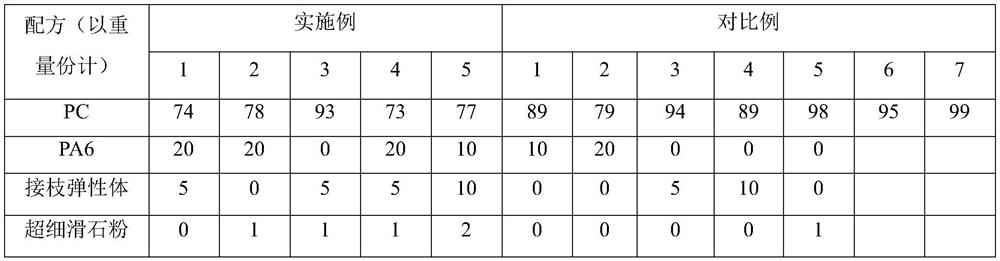

Embodiment 1-5 and comparative example 1-7

[0022] Table 1 is the component and proportioning of embodiment 1-5 and comparative example 1-7, wherein, comparative example 1 and 2, add PA6 alone, do not add graft elastomer and superfine talcum powder; comparative example 3 and 4 are grafted elastomers added alone without adding PA6 and superfine talcum powder; comparative example 5 is added superfine talcum powder without adding PA6 and grafted elastomers; comparative example 6 is added BMAT without adding PA6, grafted elastomer and superfine talc; Comparative Example 7 without adding PA6, grafted elastomer, superfine talcum and BMAT.

[0023] Among them, the PC material is bisphenol A type PC.

[0024] Among them, the relative viscosity of PA6 material is 2-4.

[0025] Wherein, the grafted elastomer material is maleic anhydride grafted ethylene-octene copolymer.

[0026] Among them, the particle size of the superfine talcum powder is 1-5 microns; the black mother is a carrier-free black mother with a carbon black conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com