Washing machine and control method thereof

A technology for washing machines and control devices, which is applied to the control devices of washing machines, other washing machines, washing devices, etc., which can solve the problems of inconvenient heating of washing water, secondary pollution of clothes, and unfavorable human health, and achieve the reduction of supporting structures and connecting lines The layout of the cables, the improvement of the level of intelligence, and the effect of strong scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

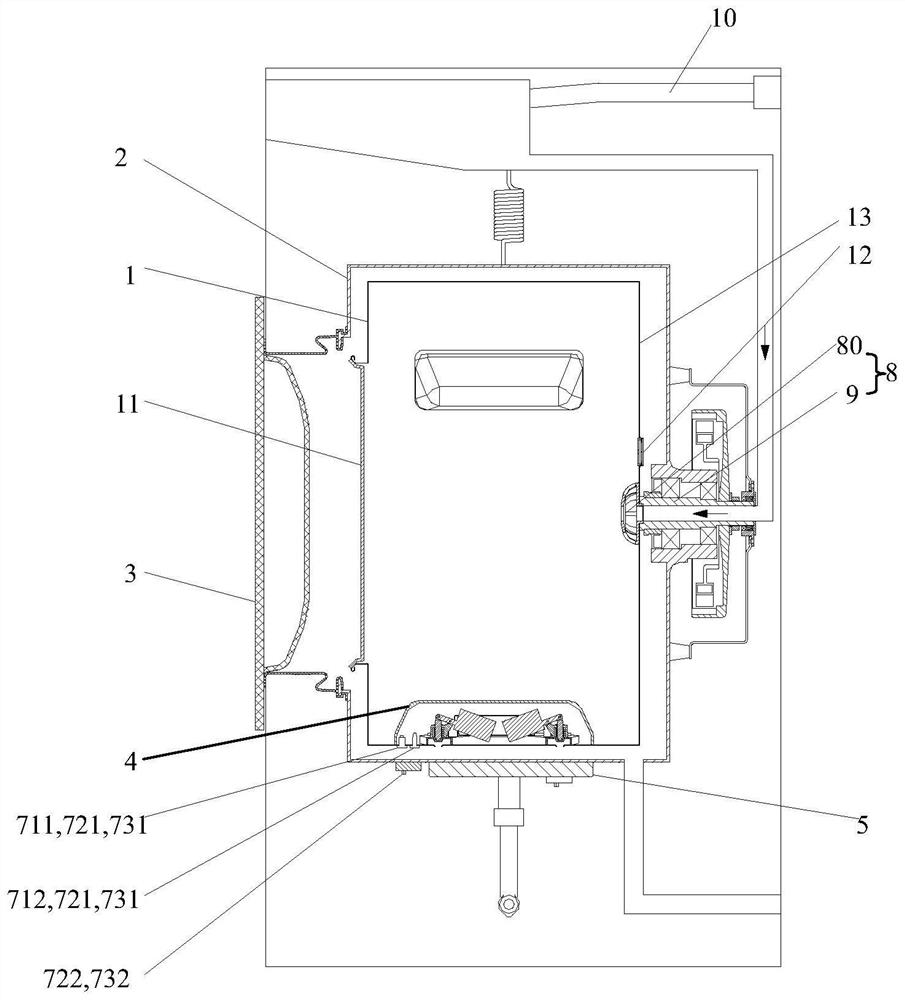

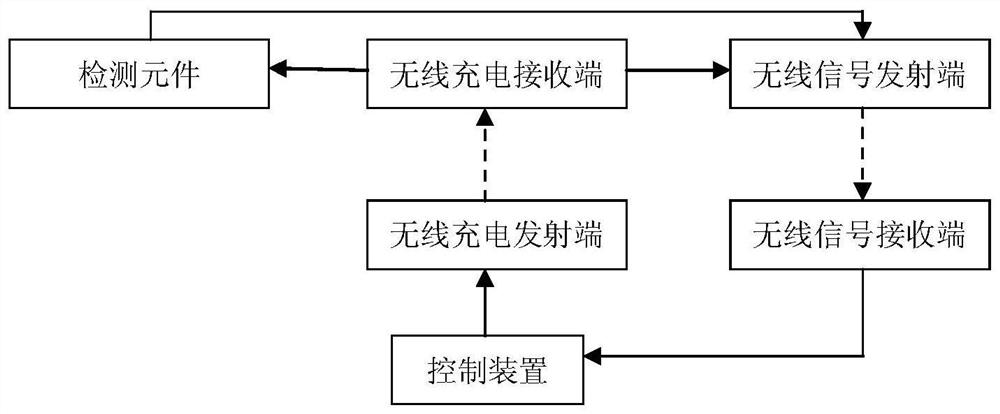

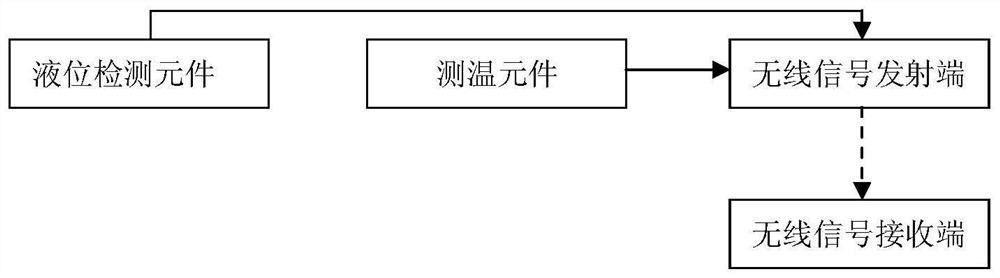

[0071] Such as figure 1 As shown, the washing machine described in this embodiment includes an inner tub 1, which holds washing water independently when washing clothes, avoiding the accumulation of dirt outside the inner tub 1 and the problems of dirt accumulation and bacterial growth caused by overflowing washing water; the temperature control module , used to control the temperature of the water in the inner cylinder 1; the temperature control module includes a control device (not shown in the figure) and a detection device for detecting the water level and water temperature in the inner cylinder 1, the The detection device and the control device are wirelessly connected. Data transmission is carried out in the form of wireless communication, which avoids setting a large number of control cables between the inner cylinder 1 and the outer cylinder 2, which will affect the rotation of the inner cylinder 1, and at the same time improves the intelligence level of the washing ma...

Embodiment 2

[0106] The main difference between this implementation and the first embodiment is that the installation positions of the detection devices are different.

[0107] Such as Figure 10 As shown, in this embodiment, the inner cylinder 1 includes an inner cylinder mouth and an inner cylinder bottom 13 arranged oppositely, an inner cylinder door 11 that can be opened and closed is arranged on the inner cylinder mouth, and the inner cylinder mouth and the inner cylinder bottom 13 pass through The side walls of the inner cylinder are connected. In this embodiment, the temperature measuring element 712 is arranged on the side wall of the inner cylinder. In order to prevent the clothes from damaging the temperature measuring element 712, an inner cylinder The protective cover 75 protrudes inside, and a cavity is formed between the protective cover 75 and the side wall of the inner cylinder. The temperature measuring element 712 is arranged in the cavity, and the protective cover 75 is ...

Embodiment 3

[0114] Such as Figure 11 As shown, this embodiment introduces the heating device 5 described in Embodiment 1 in detail.

[0115] The washing machine includes an outer cylinder 2 coaxially sleeved on the outside of the inner cylinder 1, the heating device 5 is arranged on the outer cylinder 2, and the heating device 5 is an electromagnetic heating device, so that the outer cylinder 2 The inside is heated, and the heating heat is transferred to the washing water contained in the inner tub 1 .

[0116] By arranging the above-mentioned electromagnetic heating device 5 on the outer cylinder 2, the inner cylinder 1 inside the outer cylinder 2 and the washing water inside the inner cylinder 1 are heated by electromagnetic force, so as to achieve the purpose of adjusting the temperature of the washing water in the inner cylinder 1 of the washing machine. .

[0117] In this embodiment, at least part of the inner cylinder 1 is made of metal material, so as to generate heat due to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com