A kind of anti-low temperature sheath suitable for underground buried cables

A low temperature resistance and sheathing technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of reduced transmission efficiency, easy to freeze, unfavorable cable antifreeze, etc., to enhance antifreeze ability, enhance mechanical strength, and benefit The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

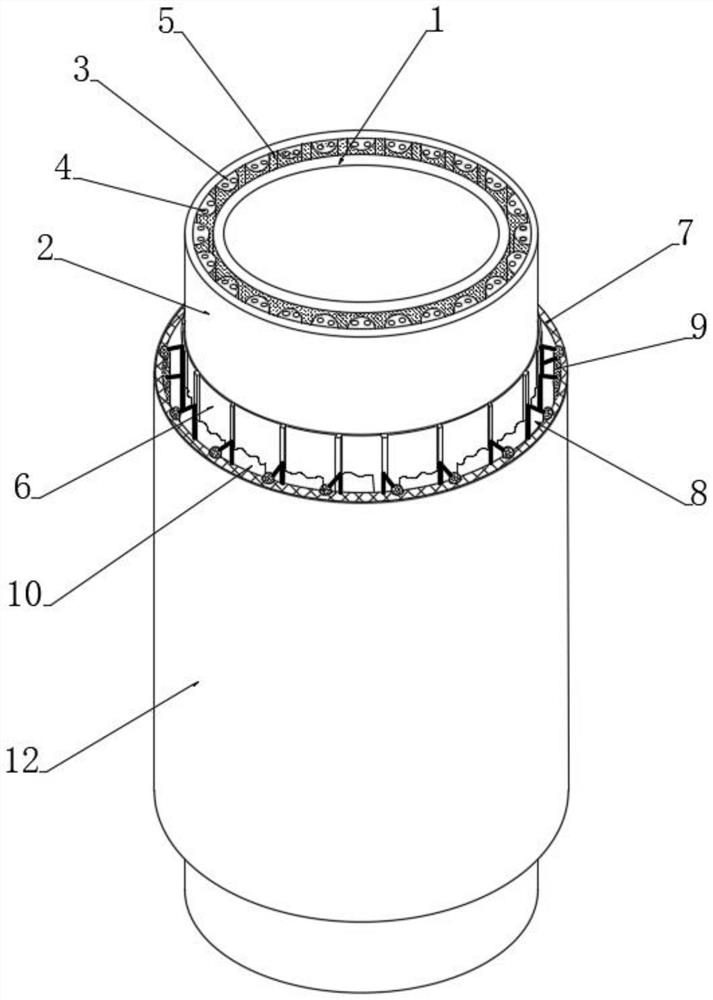

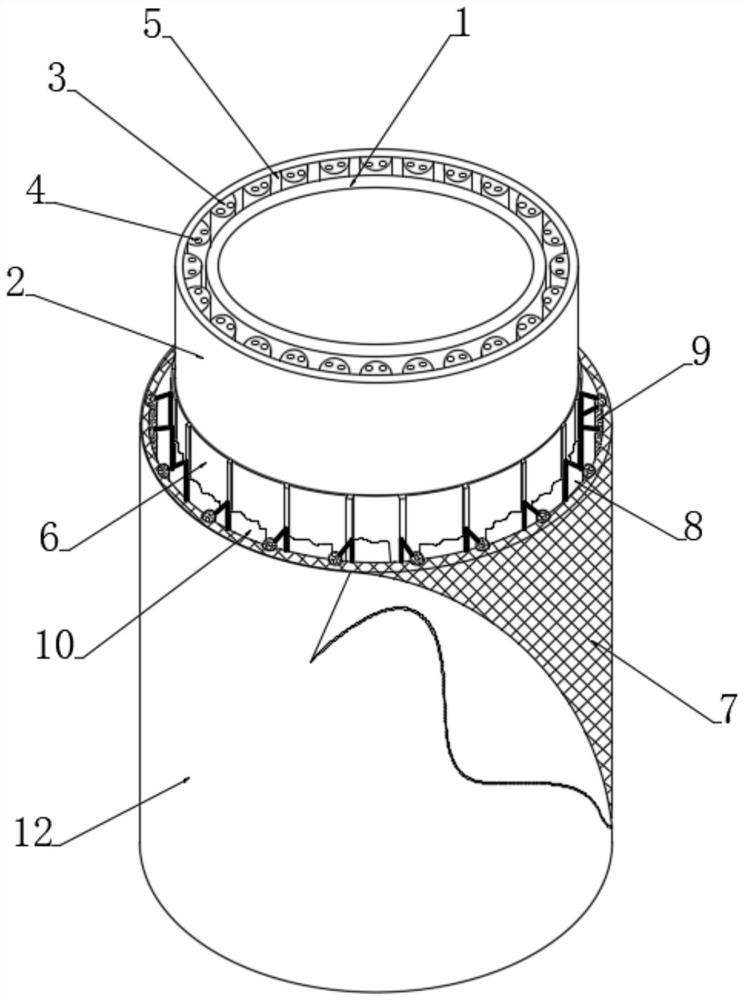

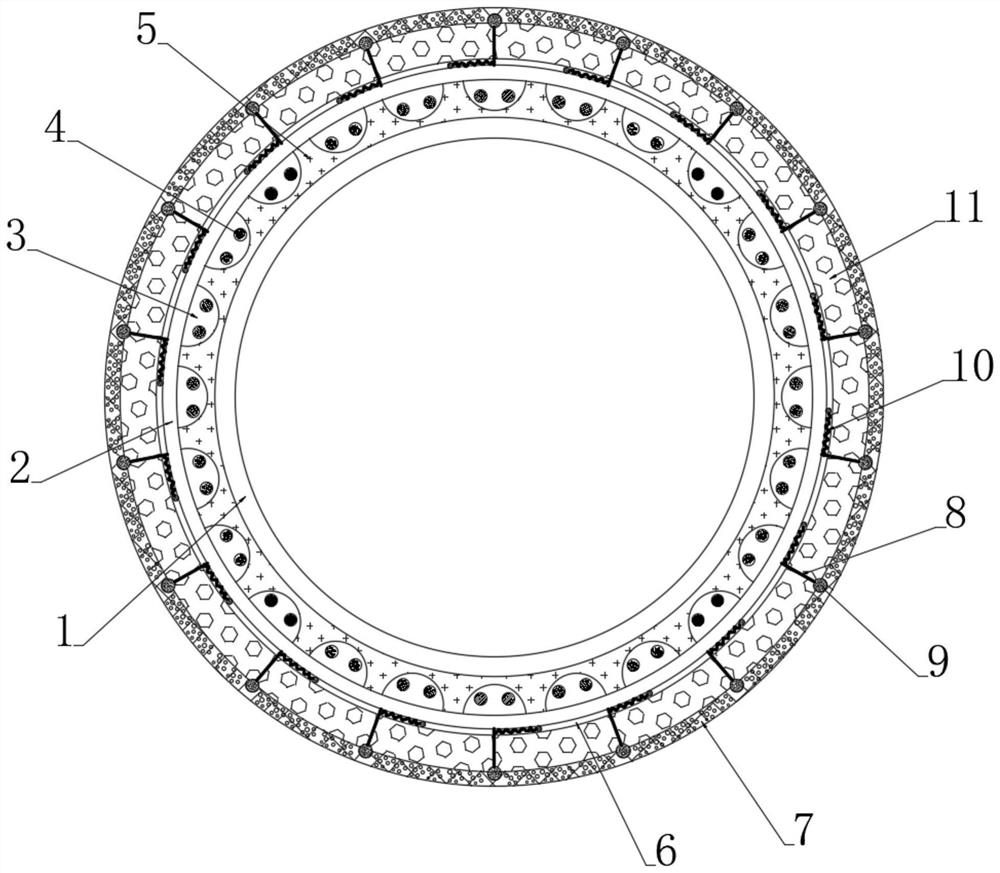

[0038] see Figure 1-3 , a low-temperature resistant sheath suitable for underground buried cables, including an inner sheath and an outer sheath fixed inside and outside the sheath, the inner sheath includes an inner sheath 1 and an outer sheath 2 stacked inside and outside, the inner sheath 1 and the outer casing 2 are provided with a heat conduction chamber, and a heat conduction layer is arranged in the heat conduction chamber, and the heat conduction layer includes a plurality of heat conduction bodies 3 annularly fixedly connected to the inner wall of the outer casing 2, and the inside of the heat conduction chamber is filled with multiple A heat conductor 3 is closely attached to a silicone conductor 5, and a pair of reinforcement cores 4 are inserted inside a plurality of heat conductors 3, and a plurality of heat conductors 3 and the silica gel conductor 5 are arranged in cooperation, which is conducive to installation on the inner layer The heat dissipation of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com