Processing technology of mung bean rice noodles

A processing technology, mung bean powder technology, applied in food drying, grain processing, food science, etc., can solve the problems of unacceptable products, complicated production technology, monotonous nutrition, etc., to reduce the global greenhouse effect, protect the ecological environment, Nutrient-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] A kind of processing technology of mung bean rice flour, comprises the steps:

[0034] S1, prepare rice and mung beans, proportion by weight, rice 0.75, mung beans 0.25, water 0.5;

[0035] S2, washing rice and mung beans;

[0036] S3, soaking the washed rice and mung beans, the soaking time of rice is 2h, and the soaking time of mung beans is 5h;

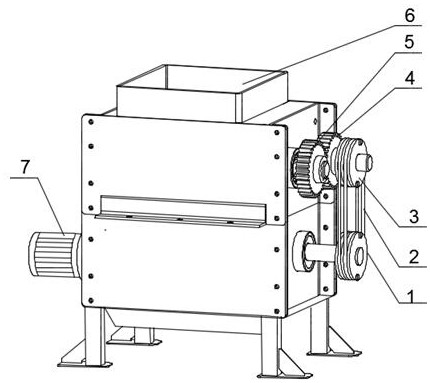

[0037] S4, putting the soaked rice and mung beans into a grinder to grind respectively, adding water and stirring the obtained rice flour and mung bean flour to prepare rice milk;

[0038] S5, filtering the prepared rice slurry, and filtering the rice slurry through an 80-mesh vibrating sieve;

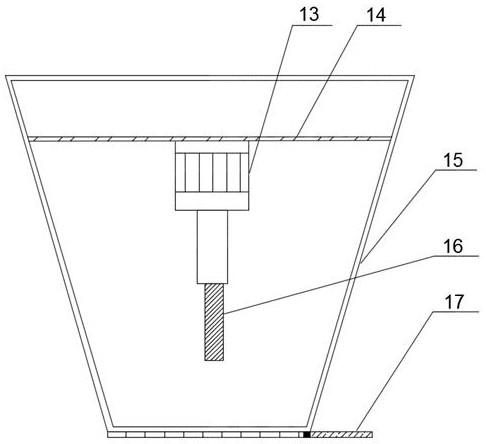

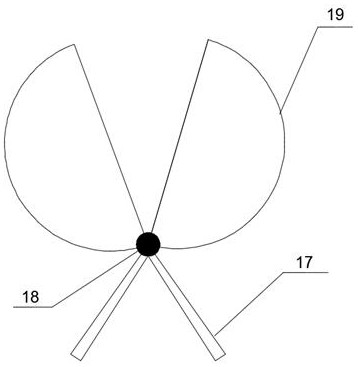

[0039] S6, put the rice milk into the rice steamer for steaming to form a uniform thickness of rice noodles;

[0040] S7, drying the steamed vermicelli, the temperature during drying is controlled at 50°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com