HDPE harvester fuel tank and preparation method thereof

A technology for fuel tanks and harvesters, applied in chemical instruments and methods, arrangement combined with internal combustion engine fuel supply, substructure, etc., can solve the problem of high requirements for raw materials and processing equipment, increased production costs, and the ability to resist fuel oil leakage not ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

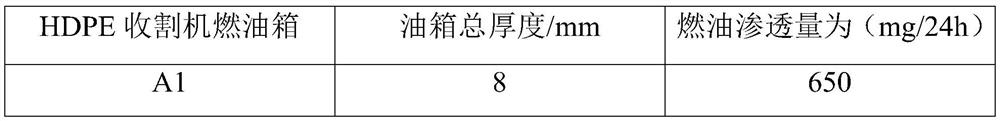

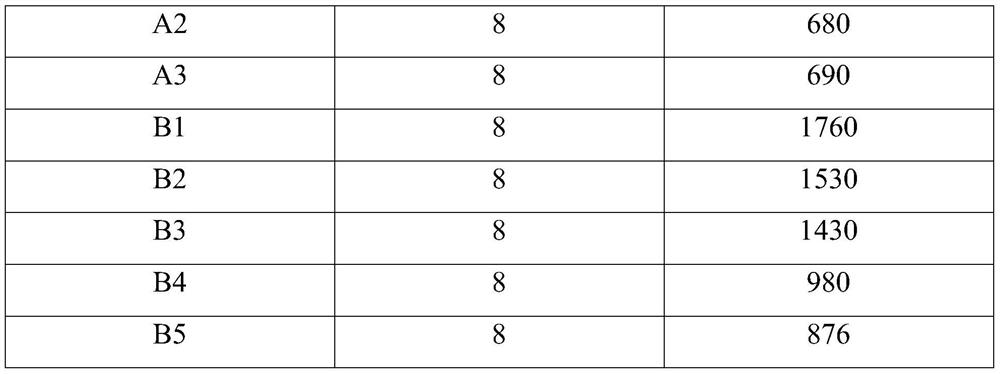

Embodiment 1

[0033] Extrude HDPE outer layer (raw material is HDPE-1, average particle size is 0.2mm), adhesive layer (maleic anhydride grafted polyethylene-1, average particle size is 0.15mm) from outside to inside by co-extrusion ), barrier layer (raw material is PA11, average particle size is 0.03mm), bonding layer (maleic anhydride grafted polyethylene-2, average particle size is 0.15mm) and HDPE inner layer (raw material is HDPE-2, average particle size The diameter is 0.01mm, and the molding process is carried out in a nitrogen environment containing 1% fluorine by volume), and the thickness ratio of HDPE outer layer, adhesive layer, barrier layer, adhesive layer and HDPE inner layer is 5:2.5:33:2.5: 2.5 to prepare the HDPE harvester fuel tank A1.

Embodiment 2

[0035] Extrude the HDPE outer layer (raw material is HDPE-2, with an average particle size of 0.1mm) and the adhesive layer (maleic anhydride grafted polyethylene-1, with an average particle size of 0.10mm) from the outside to the inside by co-extrusion ), barrier layer (raw material is PA12, average particle size is 0.01mm), bonding layer (maleic anhydride grafted polyethylene-2, average particle size is 0.10mm) and HDPE inner layer (raw material is HDPE-1, average particle size The diameter is 0.01mm, and the molding process is carried out in a nitrogen environment containing 1 vol% fluorine gas), the thickness ratio of HDPE outer layer, adhesive layer, barrier layer, adhesive layer and HDPE inner layer is 5:2:30:2: 2. To produce the HDPE harvester fuel tank A2.

Embodiment 3

[0037] Extrude HDPE outer layer (raw material is HDPE-1, average particle size is 0.3mm), adhesive layer (maleic anhydride grafted polyethylene-2, average particle size is 0.20mm) from outside to inside by co-extrusion ), barrier layer (raw material is PA12, average particle size is 0.04mm), bonding layer (maleic anhydride grafted polyethylene-1, average particle size is 0.20mm) and HDPE inner layer (raw material is HDPE-2, average particle size The diameter is 0.02mm, and the molding process is carried out in a nitrogen environment containing 1% fluorine by volume), and the thickness ratio of HDPE outer layer, adhesive layer, barrier layer, adhesive layer and HDPE inner layer is 5:3:35:3: 3. To produce the HDPE harvester fuel tank A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com