Stirring tooth granulator for organic fertilizer production and granulation process thereof

A technology of organic fertilizer and granulator, which is applied in the direction of fertilizer mixture, solid/semi-solid fertilizer, static tank/tank granulation, etc. It can solve the problems of sterilization lamp operation, insufficient granulation, low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

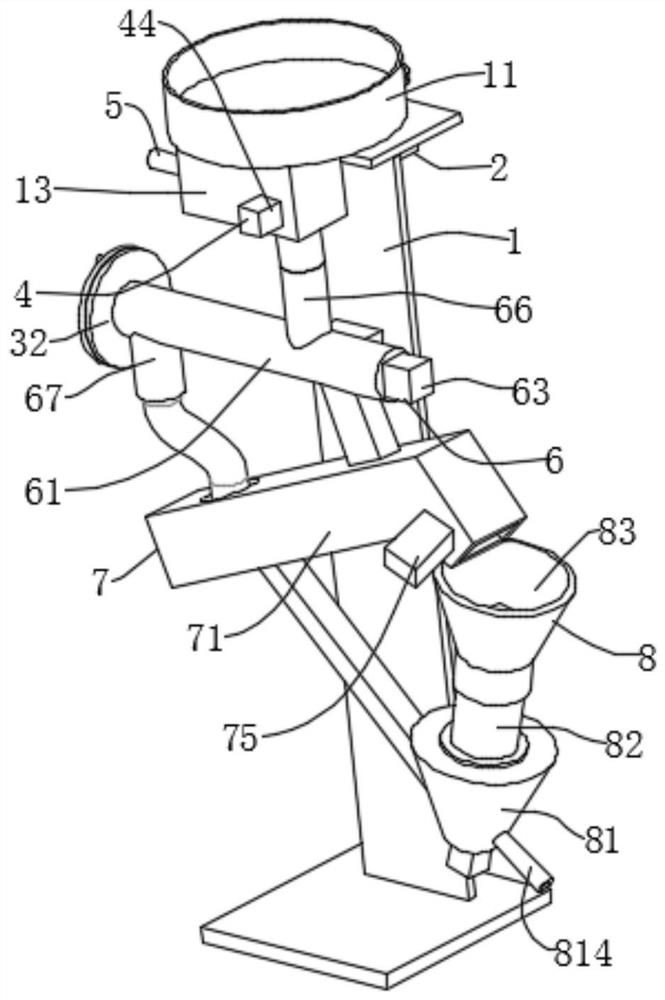

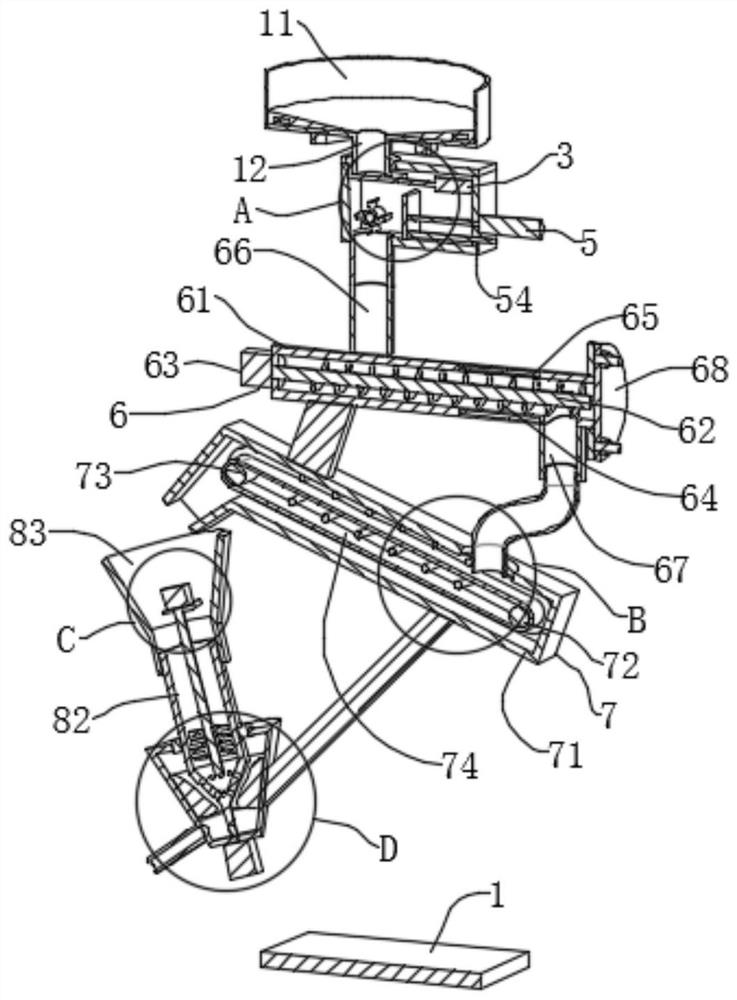

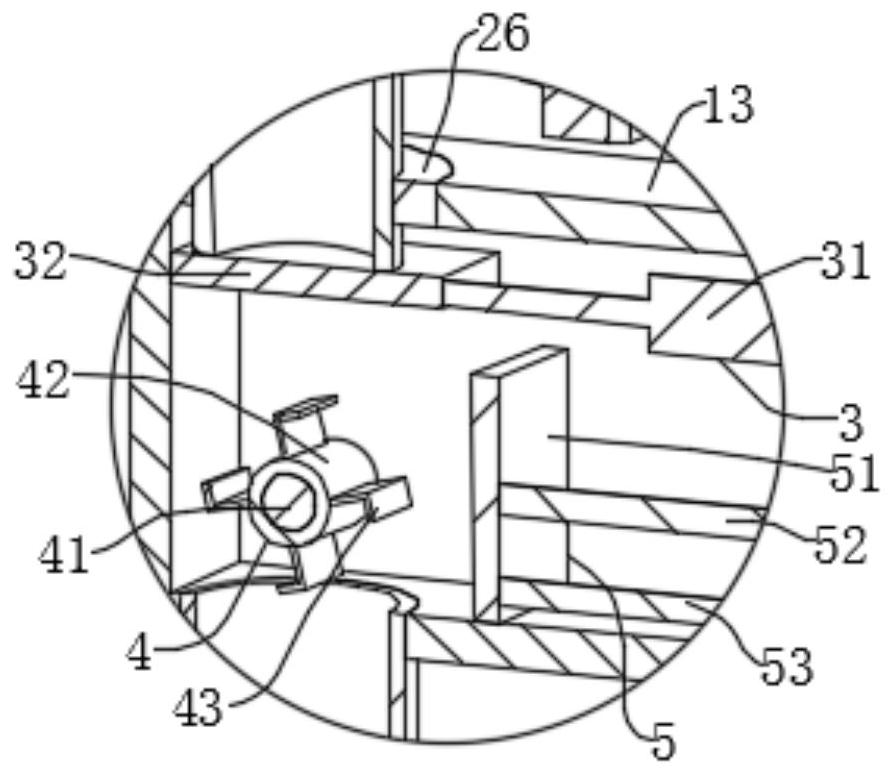

[0047] refer to figure 1 and figure 2 , a tooth-stirring granulator for organic fertilizer production, mainly includes the following parts:

[0048] Frame 1 as the main support;

[0049] Rotate the drying tray 11 connected to the frame 1;

[0050] A power assembly 2 for driving the drying disc 11 to rotate;

[0051] Connected to the discharge pipe 12 fixed at the bottom of the drying tray 11;

[0052] A blocking assembly 3 for blocking the discharge pipe 12;

[0053] Fixed box 13 fixed on the frame 1;

[0054] A stirring assembly 4 for driving the stirring of materials in the fixed box 13;

[0055] The pushing assembly 5 arranged in the fixed box 13;

[0056] An extruding assembly 6 for receiving the material stirred by the agitating assembly 4, and the extruding assembly 6 is used for crushing the material;

[0057] A reprocessing component 7 for conveying, heating and sterilizing the crushed material through the crushing component;

[0058] Rotate the support tube ...

Embodiment 2

[0069] The difference from Example 1 is that: a kind of granulation process of a tooth-stirring granulator for organic fertilizer production is also provided, specifically comprising the following steps:

[0070] S1. Fill the crushed organic fertilizer into the drying pan 11 for drying operation, and use the power assembly 2 to drive the drying pan 11 to rotate. When drying, control the drying temperature to 80°C and control the drying time to 18 hours ;

[0071] S2, using the plugging assembly 3 to transfer the material in the drying tray 11 to the fixed box 13, and using the stirring assembly 4 to stir the material;

[0072] S3, using the extrusion assembly 6 to transfer the material in the fixed box 13 to the extrusion cylinder 61 in the extrusion assembly 6, and start the third servo motor 63 at the end of the extrusion cylinder 61 to crush the material;

[0073] S4. Utilize the fourth servo motor 75 in the reprocessing assembly 7 to drive the conveyor belt 74 to transpor...

Embodiment 3

[0076] The difference from Example 1 is that: a kind of granulation process of a tooth-stirring granulator for organic fertilizer production is also provided, specifically comprising the following steps:

[0077] S1. Fill the crushed organic fertilizer into the drying pan 11 for drying operation, and use the power assembly 2 to drive the drying pan 11 to rotate. When drying, control the drying temperature to 90°C and control the drying time to 20h ;

[0078] S2, using the plugging assembly 3 to transfer the material in the drying tray 11 to the fixed box 13, and using the stirring assembly 4 to stir the material;

[0079] S3, using the extrusion assembly 6 to transfer the material in the fixed box 13 to the extrusion cylinder 61 in the extrusion assembly 6, and start the third servo motor 63 at the end of the extrusion cylinder 61 to crush the material;

[0080] S4. Utilize the fourth servo motor 75 in the reprocessing assembly 7 to drive the conveyor belt 74 to transport the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com