Carbon dioxide trapping system and method based on blast furnace slag flushing water waste heat recycling

A blast furnace slag flushing water and carbon dioxide technology, which is applied in the field of blast furnace heat energy recovery, can solve the problems of increasing carbon capture cost, reboiler consuming large steam or electric energy, etc., to ensure continuous stability of heating supply, reduce energy consumption burden, The effect of reducing energy consumption for regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

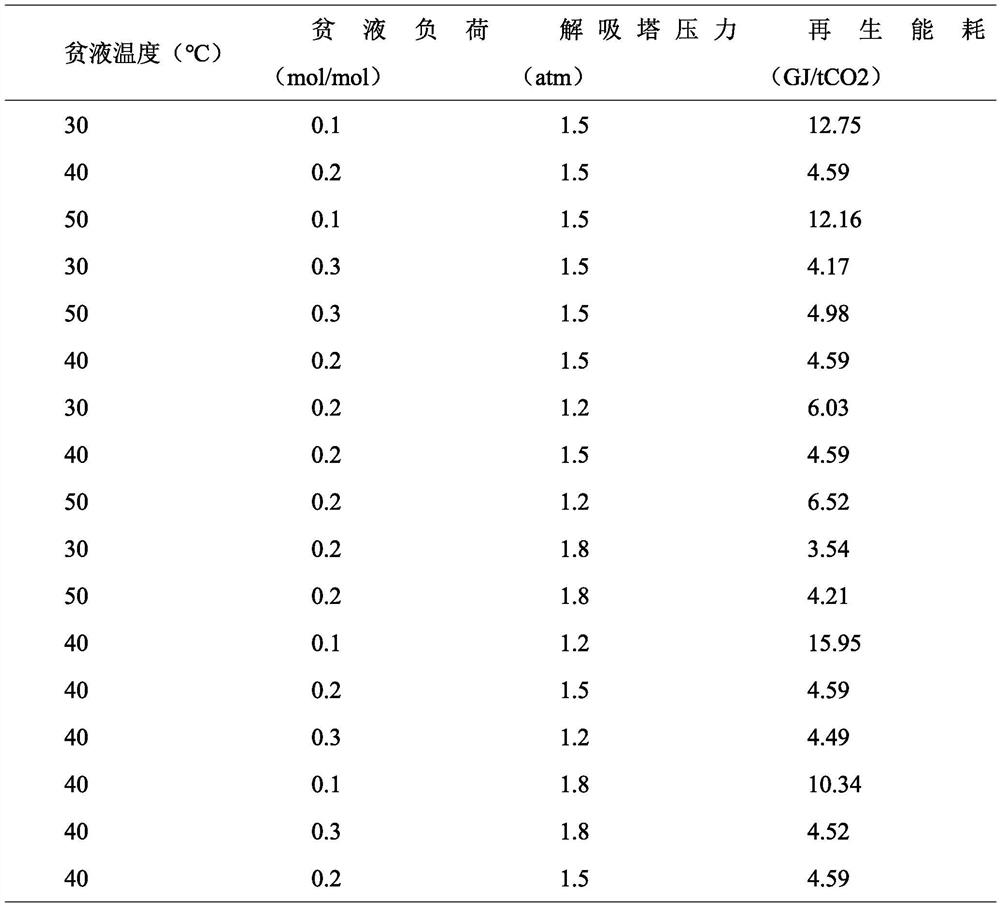

Examples

Embodiment

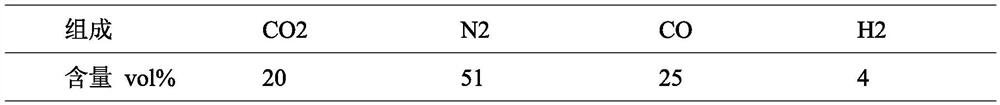

[0042] Table 1 Composition of blast furnace gas

[0043]

[0044] In this implementation case, the carbon dioxide capture and separation system of the present invention is used to separate carbon dioxide from blast furnace gas (gas temperature 40°C, carbon dioxide content 20%).

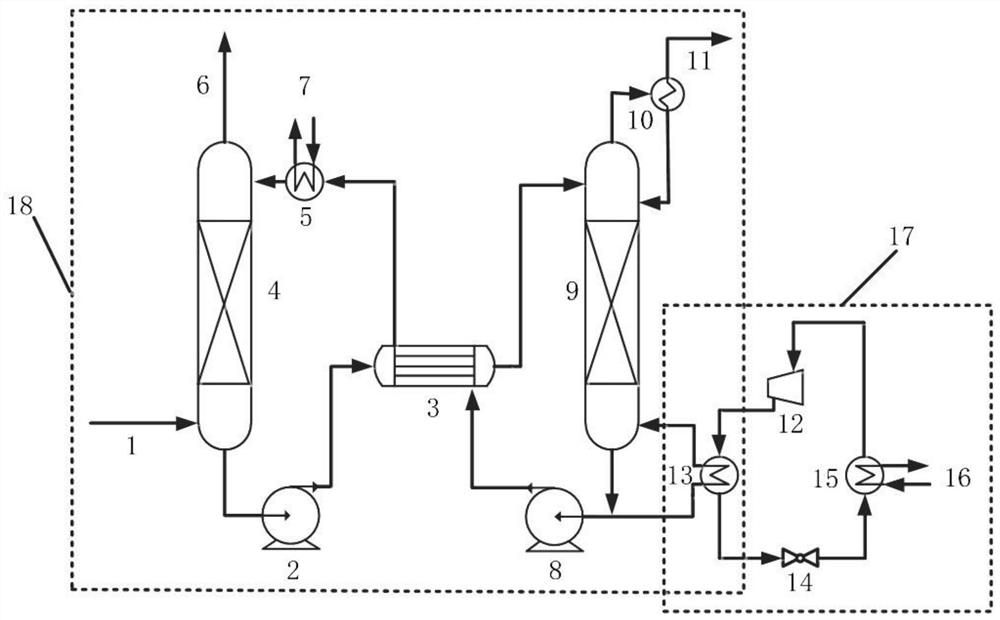

[0045] The carbon dioxide capture and separation system includes blast furnace gas 1, purified gas 6, absorption tower 4, desorption tower 9, lean liquid pump 8, rich liquid pump 2, lean liquid heat exchanger 3, lean liquid condenser 5, Gas-liquid separator 10, reboiler. The dust-removed, desulfurized and denitrified blast furnace gas 1 enters the absorption tower 4 from bottom to top to contact with the lean liquid absorbent sprayed from top to bottom in the absorption tower, and the gas-liquid two-phase separation takes place on the packing surface. Heat and mass transfer, so that the CO in the lean liquid and blast furnace gas 1 2 A chemical reaction occurs, and most of the CO in blast furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com