A metal plate and strip temperature measuring device and temperature control method for a roller quenching machine

A metal strip and temperature measuring device technology, applied in the direction of quenching device, process efficiency improvement, heat treatment process control, etc., can solve the problems of difficult temperature measurement, narrow space, poor process conditions, etc. The effect of long life and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] In this embodiment, taking the quenching heat treatment of the metal plate and strip used in the roller quenching machine as an example, the specific implementation scheme of the temperature measuring device for the metal plate and strip is described:

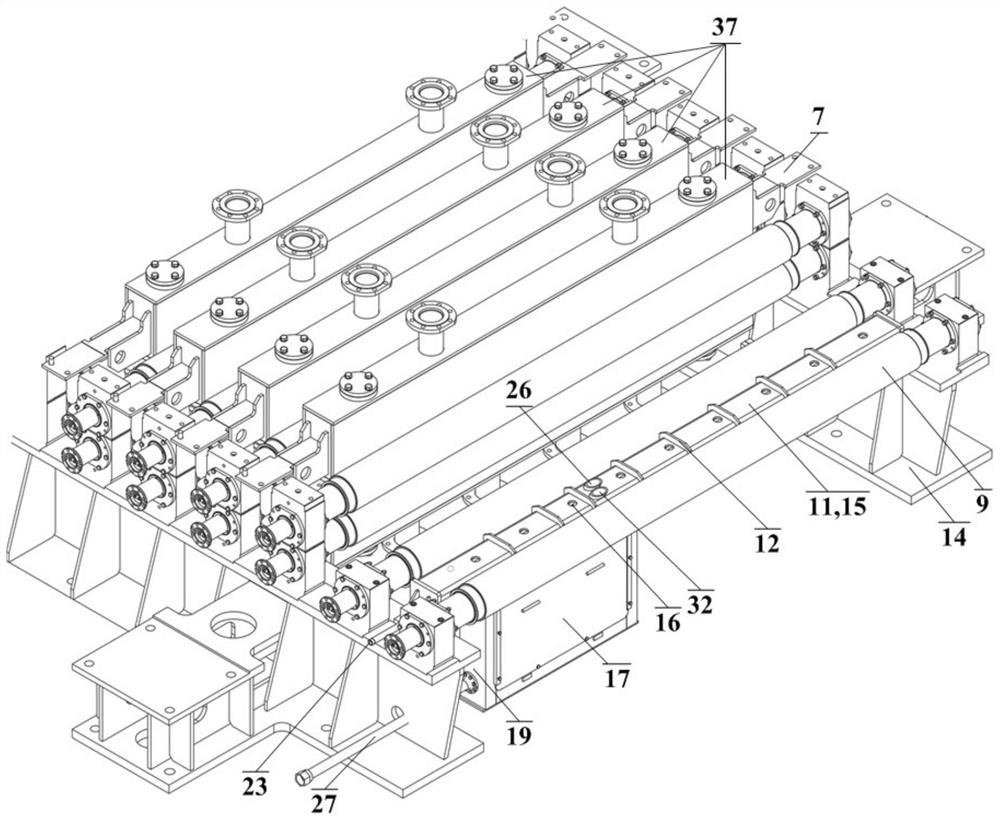

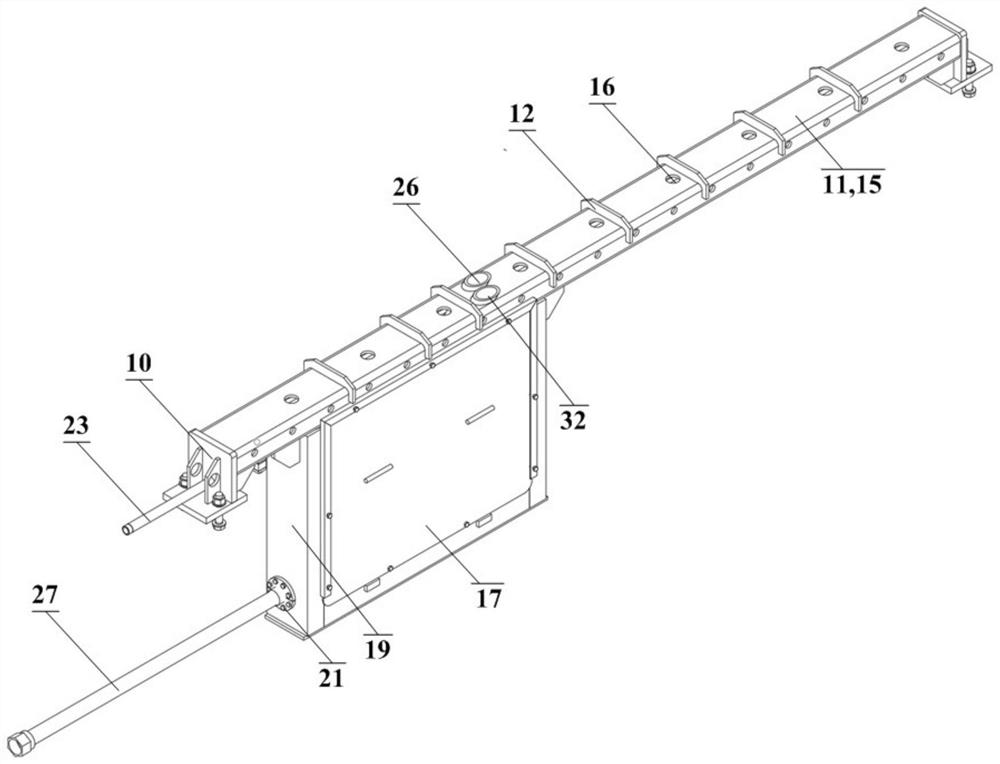

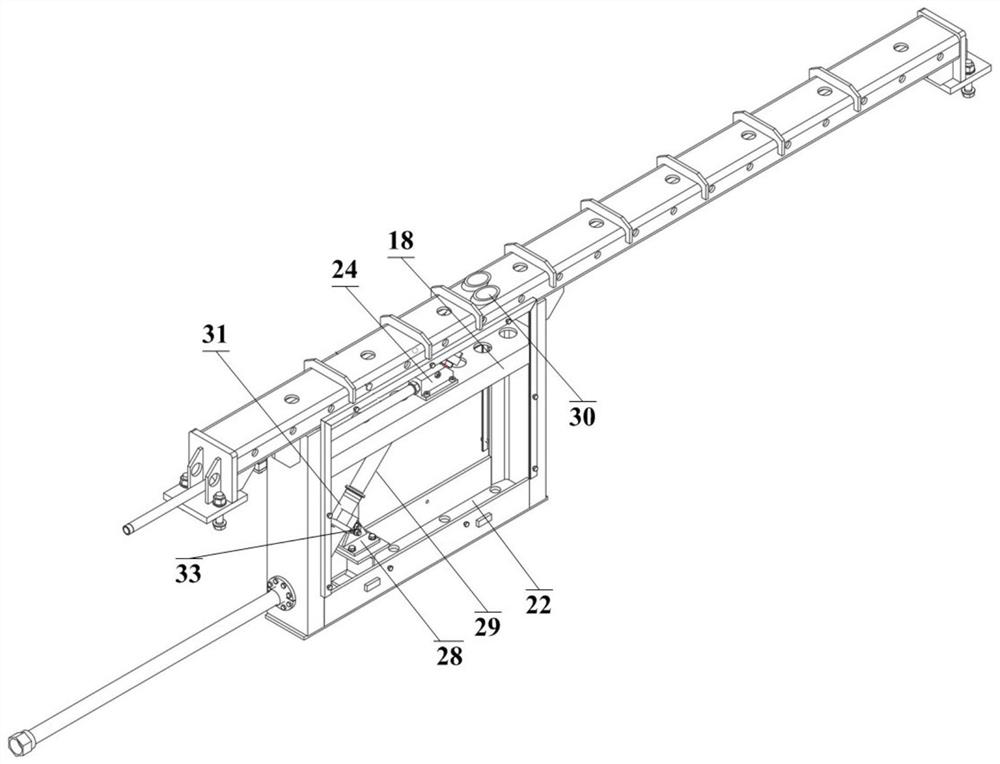

[0064] see figure 1 , 2 , 3, 4, and 5, a metal plate and strip temperature measuring device for a roller quenching machine, the roller quenching machine includes sequentially setting a rolling quenching section 7, a transition roller table 9 and an atmospheric quenching section 8. The temperature measuring device is installed between the transition roller tables 9, and is used to measure the temperature of the metal plate and strip passing through the roll quenching section 7; the temperature measuring device includes: a protection mechanism and a The waterproof box below; the protective mechanism is used to protect the waterproof box; the waterproof box includes a box body and a purging mechanism and a temperature meas...

Embodiment approach

[0076] see Figure 6 As shown, the temperature measurement method includes: speed temperature control method and water volume temperature control method; for the temperature control system, the speed temperature control method only needs to change the speed of the roller table, which is simple and effective to implement, and is the preferred temperature control method; water volume control method The temperature method needs to adjust the opening degree of the control valve of the water supply pipeline of each nozzle. The closed-loop control adjustment takes a long time to adjust, and the influence on the temperature is not very intuitive. It is used as an alternative temperature control method; The speed will cause problems such as the deterioration of the quenched plate shape of the metal plate and strip. Therefore, if the preferred speed temperature control method cannot achieve temperature control within the allowable range, the water volume temperature control method is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com