A hydraulic bushing

A technology of hydraulic bushing and liquid inlet hole, which is applied in the direction of spring/shock absorber, shock absorber, shock absorber-spring combination, etc. It can solve the problems of difficult to achieve damping effect, poor damping effect, lack of damping function, etc. , to achieve good vibration reduction and vibration isolation effects, simple structure, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

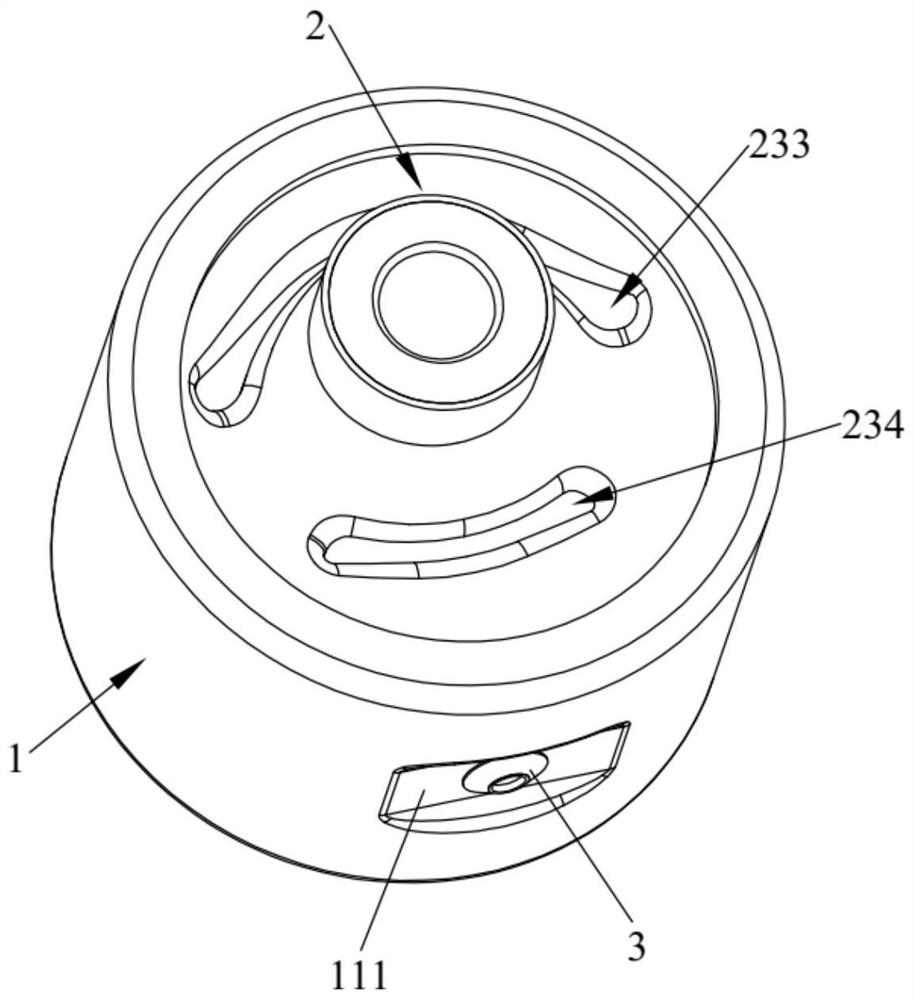

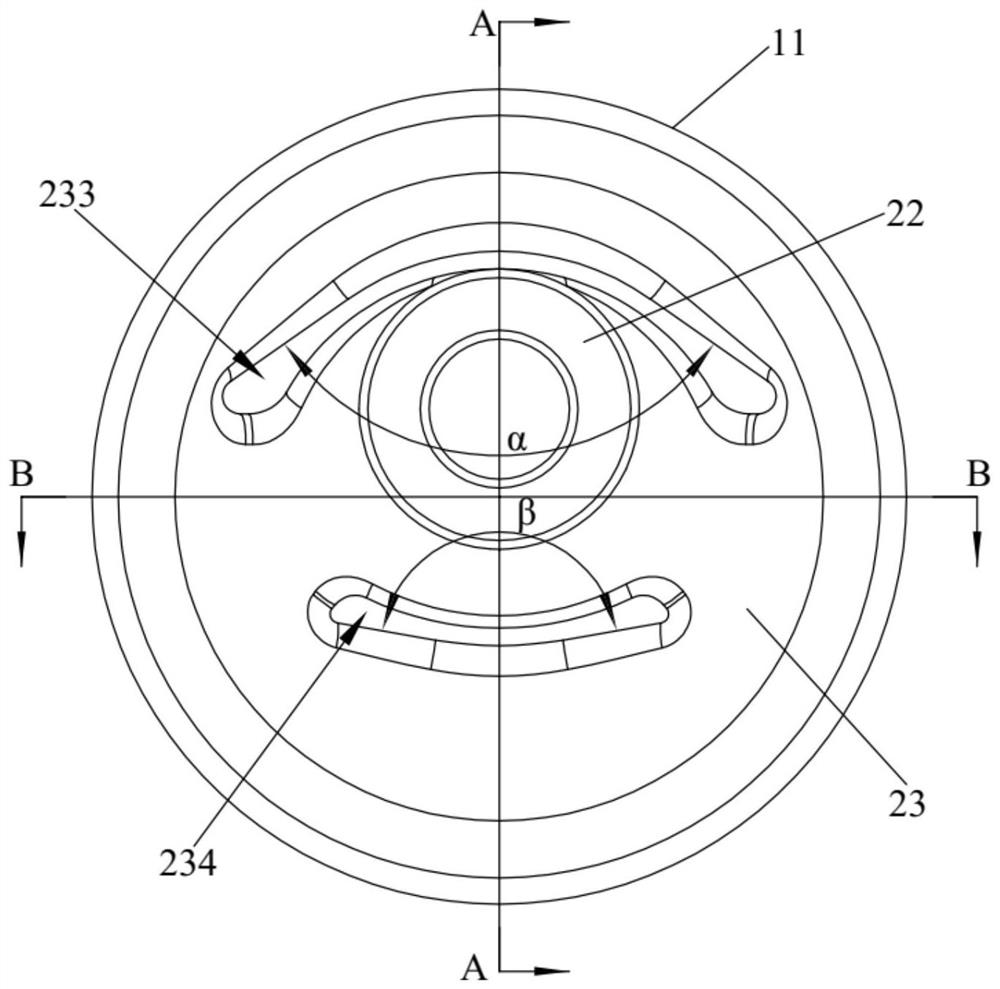

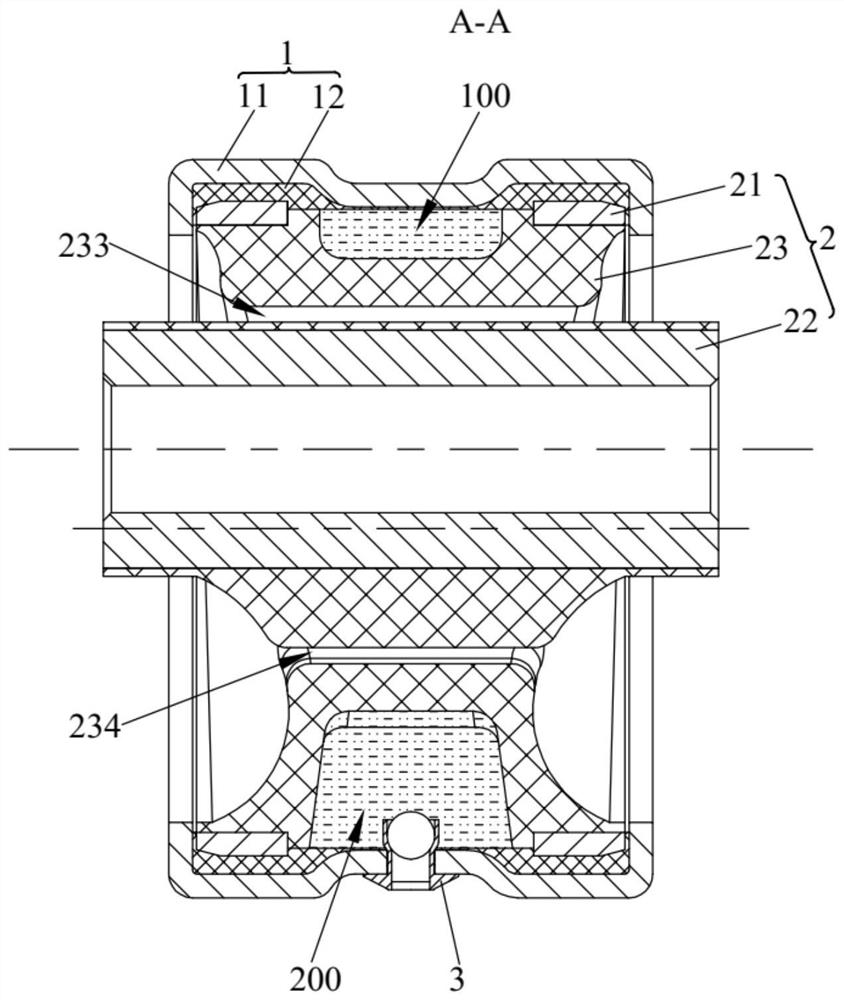

[0034] As shown in FIG. 1-FIG. 4, the present embodiment provides a hydraulic bushing, including an outer glued part 1 and an inner glued part 2. in,

[0036] In this embodiment, the sealing liquid is silicone oil. Compared with glycol sealing fluid, silicone oil is more conducive to improving damping and hysteresis

[0037] The present embodiment provides a pressing bushing, through the structure of the upper chamber 100 and the lower chamber 200 (including length, section and

[0038] The damping of the hydraulic bushing provided in this embodiment is greater than 5N*S / mm, and the hysteresis angle is greater than 30°, while the resistance of the general rubber bushing is greater than 30°.

[0040] The outer glued part 1 and the inner glued part 2 are all vulcanized using a special vulcanization mold, and the vulcanization surface roughness needs to be guaranteed.

[0041] As shown in FIGS. 3 and 4, the depth of the lower chamber 200 is greater than the depth of the upper chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| damping | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com