Mechanical reciprocating type multistage fire grate overhauling construction method

A construction method and reciprocating technology, applied in the combustion method, mobile grate, grate and other directions, can solve the problems of low work efficiency, high cost and long maintenance time on site, and achieve strong construction specialization and construction efficiency. High, improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

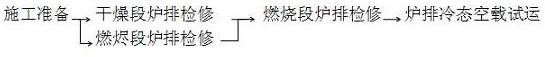

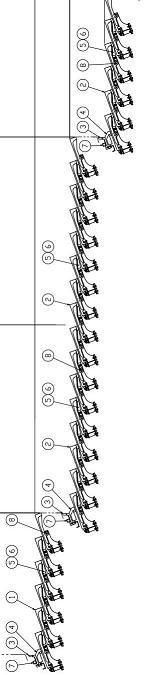

[0017] A mechanical reciprocating multi-stage fire grate maintenance construction method is characterized in that it includes the following construction steps:

[0018] Ⅰ. Construction preparation

[0019] Lay a 5mm thick anti-falling steel plate in the ash hopper of the air chamber under the grate, and set up a protective fence above the slag opening at the front end of the grate in the burner section to clean up the debris on the pusher and grate in the furnace;

[0020] Ⅱ. Overhaul of grate in drying section

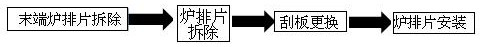

[0021] Use electric picks and crowbars to remove the refractory bricks above the end partition. When removing the refractory bricks, communicate with the insulation pouring professional about the scope of removal. Try to remove only one or two layers of refractory bricks above the end partition to reduce the workload of refractory brick restoration. ;Take out the fixing hardware 7 of the end stops on both sides, and use a crowbar to take out the end spacer 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com