Numerical simulation method for solvent diffusion process in curing process of coated textile material

A textile material and diffusion process technology, applied in CAD numerical modeling, design optimization/simulation, electrical digital data processing, etc., can solve the problems that the diffusion mechanism has not yet been resolved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

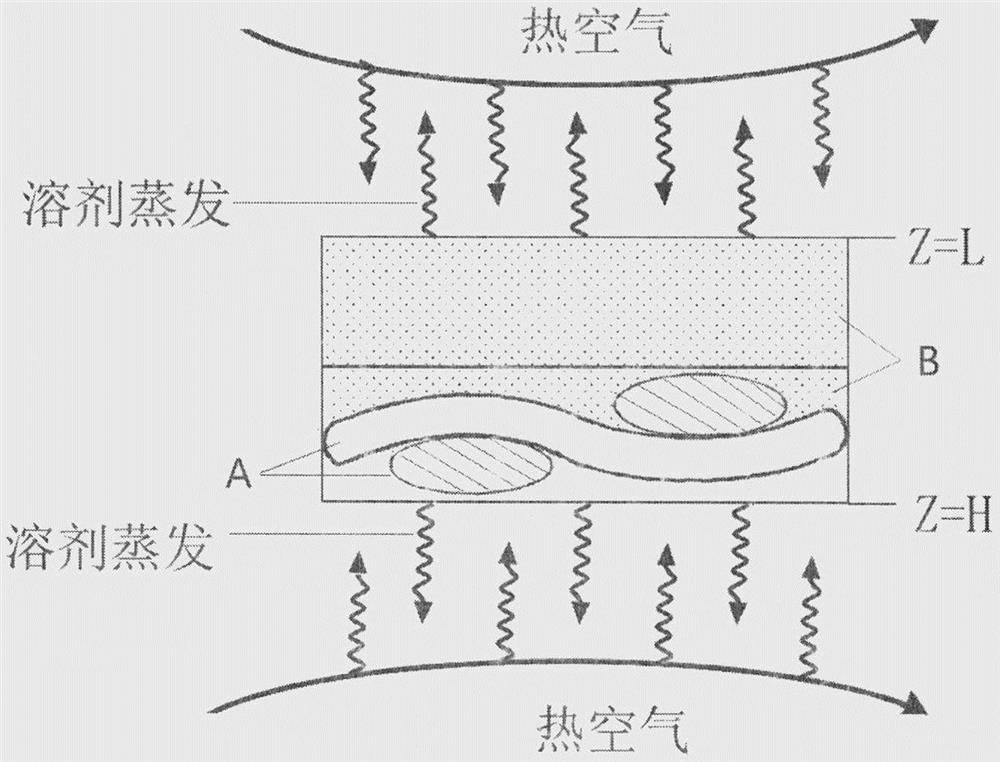

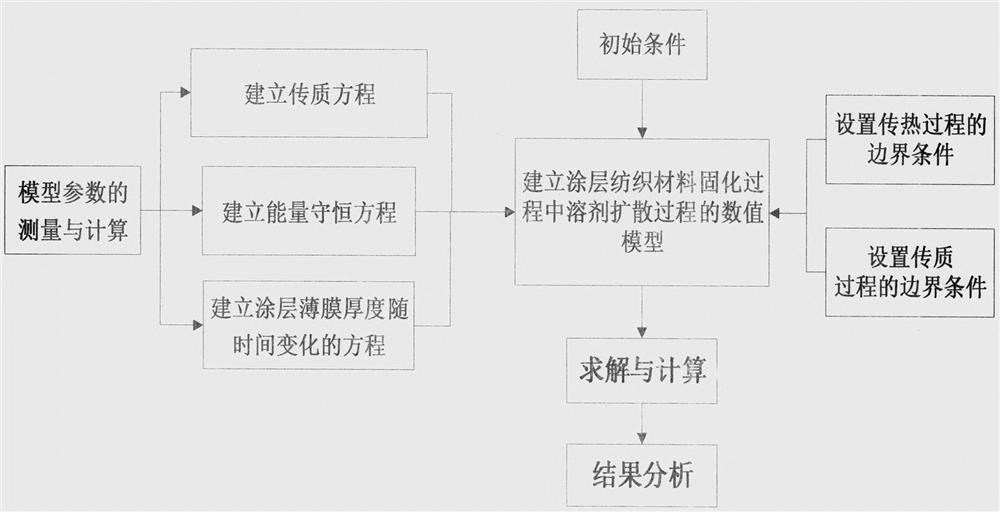

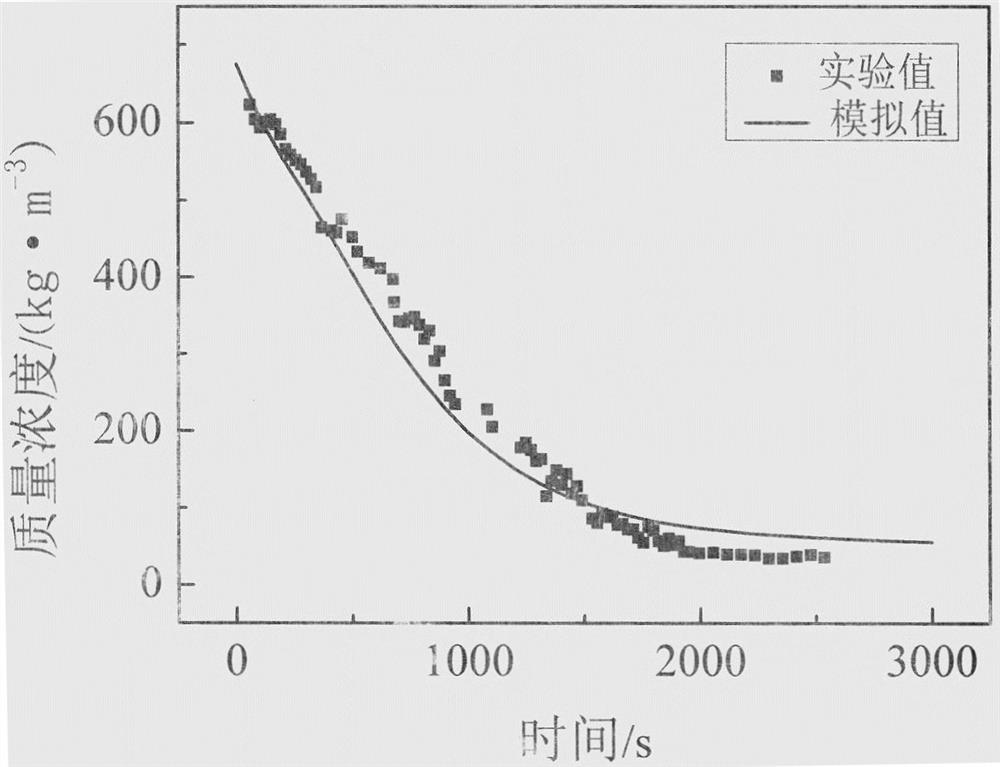

[0043]This embodiment provides a numerical simulation method (method for short) of the solvent diffusion process in the curing process of coated textile materials. This method is used to numerically simulate the curing process of a plain weave coated glass fiber fabric with a fabric thickness of 0.7 mm, while studying different The diffusion of the solvent in the coated glass fiber fabric system based on porosity is to explore the influence of the porosity of the substrate on the diffusion time of the solvent. The coating solution used is PMMA coating solution and the solvent is acetone. The specific steps of the method are as follows:

[0044]Step 1: Obtain the free volume parameters of the solvent and polymer in the coating liquid system based on the free volume theory, so as to obtain the mutual diffusion coefficient D of the solvent in the coating liquidi, And set the initial conditions of the diffusion model: the solvent mass fraction in the PMMA coating solution is 80%, the initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com