Stable and high-performance proton exchange membrane fuel cell catalyst slurry and preparation method thereof

A proton exchange membrane and catalyst slurry technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of poor stability of catalyst slurry and poor performance of finished membrane electrodes, and achieve improved performance, slurry stability, The effect of increasing the number of accessible protons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

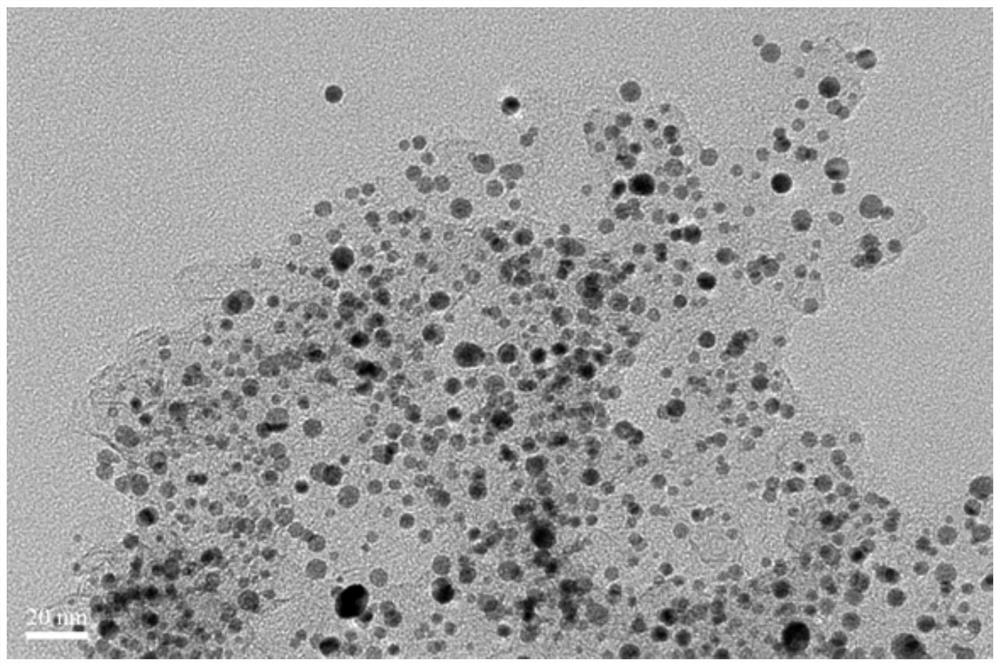

Image

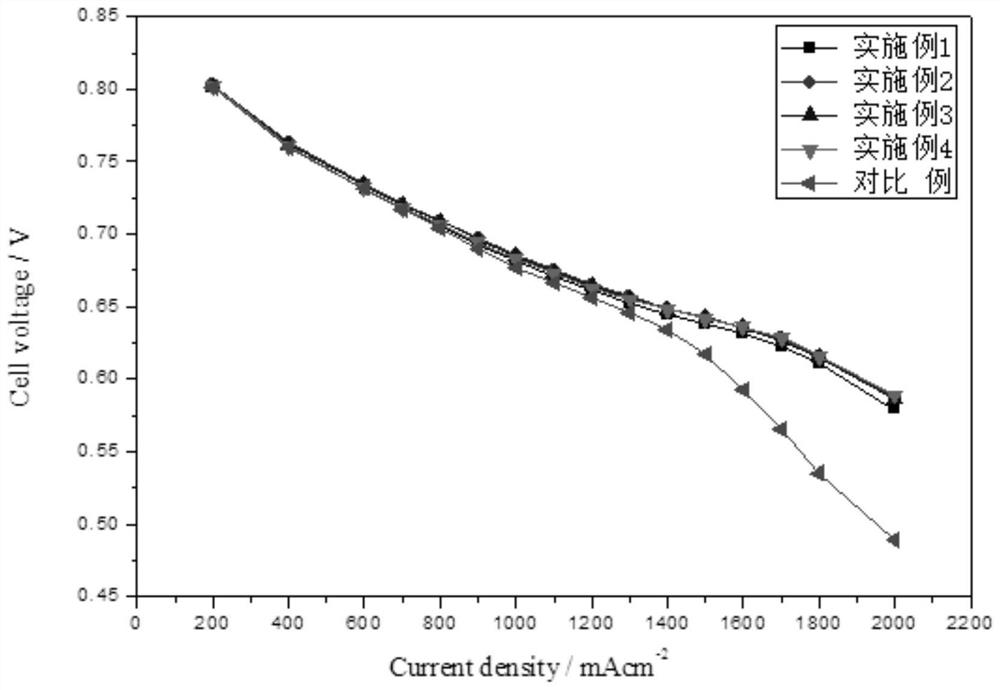

Examples

preparation example Construction

[0035] A method for preparing a stable and high-performance proton exchange membrane fuel cell catalyst slurry, comprising the following steps:

[0036] 1) Mixing water and isopropanol in mass ratios (1-9):1 and 1:(1-9) respectively to prepare a first mixed solution and a second mixed solution;

[0037] 2) Mix the first mixed solution with 5-20wt% Nafion solution, and use a high-shear disperser to disperse for 0.5-1h at a shear speed of 10000-15000rpm at 0-20°C to obtain a Nafion mixed solution; , during the dispersion process, it is necessary to seal the Nafion solution, slowly increase the shear speed at the beginning of the dispersion, and slowly decrease the shear speed at the end of the dispersion;

[0038] 3) Mix the second mixed solution with the Pt / C catalyst, and use a high-shear disperser to disperse at a shear speed of 10000-20000rpm at 0-10°C for 0.5-2h to obtain a catalyst slurry; wherein, dispersing During the process, it is necessary to seal the catalyst and th...

Embodiment 1

[0047] A method for preparing a stable and high-performance proton exchange membrane fuel cell catalyst slurry, comprising the following steps:

[0048] 1) Mix 51.12g deionized water and 12.78g isopropanol to obtain the first mixed solution, and mix 12.78g deionized water and 51.12g isopropanol to obtain the second mixed solution;

[0049] 2) Mix the first mixed solution with 7.2g 5wt% Nafion solution, and use a high-shear disperser to disperse for 0.5h at a shear speed of 10000rpm at 10°C to obtain a Nafion mixed solution; wherein, during the dispersion process, It is necessary to seal the Nafion solution, slowly increase the shear speed at the beginning of the dispersion, and slowly decrease the shear speed at the end of the dispersion;

[0050] 3) Mix the second mixed solution with 1 g of Pt / C catalyst (Pt content 60%), and use a high-shear disperser to disperse for 1 h at a shear speed of 15,000 rpm at 5° C. to obtain a catalyst slurry; wherein, During the dispersion proc...

Embodiment 2

[0053] A method for preparing a stable and high-performance proton exchange membrane fuel cell catalyst slurry, comprising the following steps:

[0054] 1) Mix 38.84g deionized water and 25.56g isopropanol to obtain the first mixed solution, and mix 25.56g deionized water and 38.84g isopropanol to obtain the second mixed solution;

[0055] 2) Mix the first mixed solution with 7.2g 5wt% Nafion solution, and use a high-shear disperser to disperse for 0.5h at a shear speed of 10000rpm at 10°C to obtain a Nafion mixed solution; wherein, during the dispersion process, It is necessary to seal the Nafion solution, slowly increase the shear speed at the beginning of the dispersion, and slowly decrease the shear speed at the end of the dispersion;

[0056] 3) Mix the second mixed solution with 1 g of Pt / C catalyst (Pt content 60%), and use a high-shear disperser to disperse for 1 h at a shear speed of 15,000 rpm at 5° C. to obtain a catalyst slurry; wherein, During the dispersion proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com