Polishing pad cleaning solution and use method thereof

A cleaning liquid and polishing pad technology, which is applied in the field of silicon wafer polishing pad cleaning, polishing pad cleaning liquid, and polishing pad cleaning liquid after silicon wafer circular polishing, which can solve the problems of clogging the pores of polishing pads, silicon wafer surface deformation, and dethickening rate Decrease and other problems to achieve the effect of reducing scratch rate, reducing surface tension and preventing redeposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

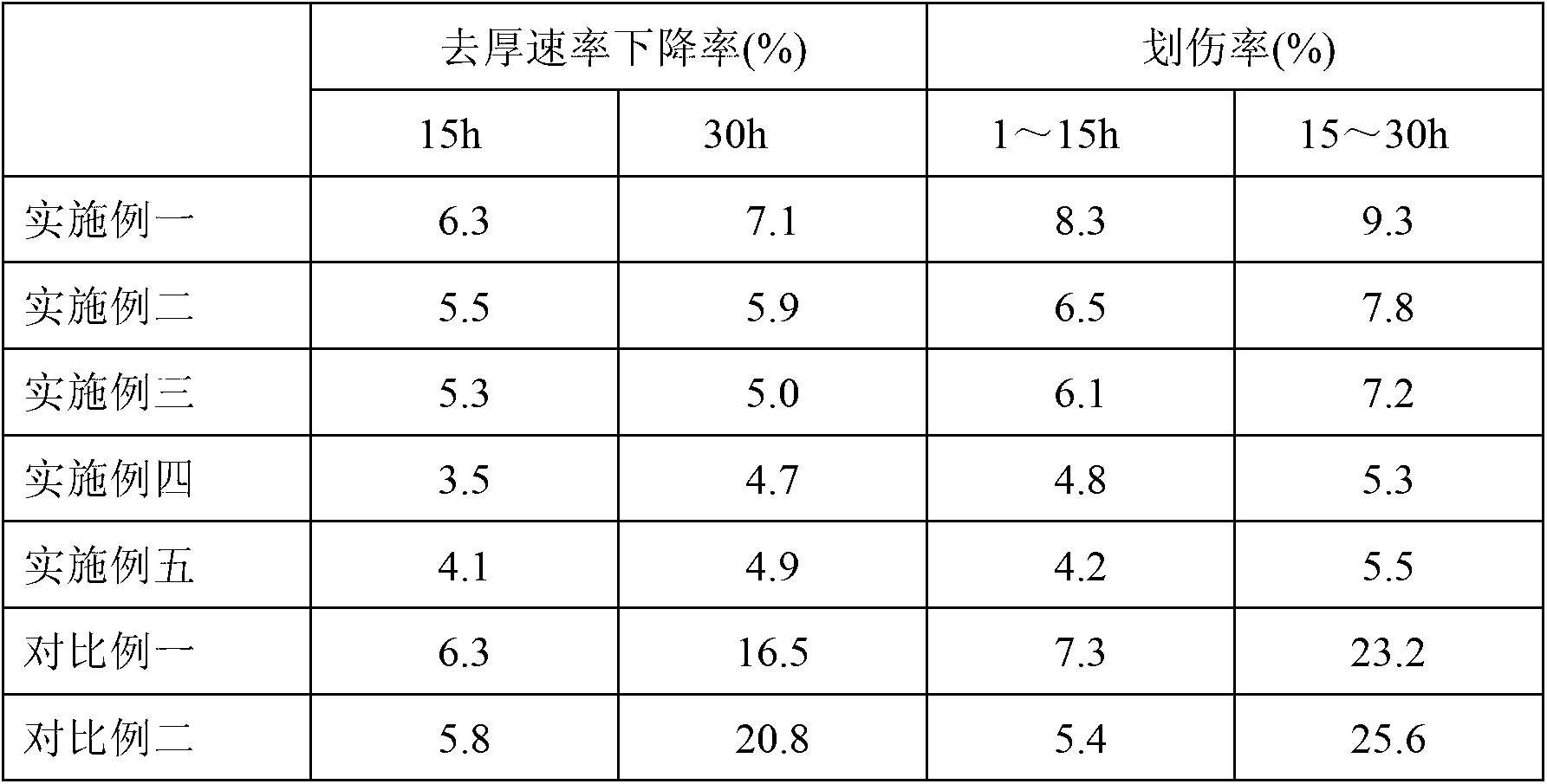

Examples

Embodiment 1

[0041] Preparation of cleaning solution: Add polyoxyethylene ether nonionic surfactant, cleaning aid, anti-caking agent, solubilizer, wetting agent and pH regulator to deionized water in sequence under constant stirring, and continue Stir until well combined. The content of each component is respectively: polyoxyethylene ether nonionic surfactant (JFC-E) 1wt%, cleaning aid (sodium tripolyphosphate) 3wt%, caking inhibitor (polyacrylic acid) 0.1wt%, increase Solvent (ethanol) 20wt%, wetting agent (tetraethylamine perfluorooctane sulfonate) 0.04wt%, pH regulator (ammonia) 0.1wt%; the pH of the cleaning solution is 8.0.

[0042] Cleaning method: scrub the polishing pad once with deionized water after using it for 30 minutes; scrub it once with the cleaning solution of the present invention after every 1 hour of using the polishing pad. Specifically: dilute the prepared cleaning solution by 20 times, use a common PVA brush on the polished non-woven polishing pad, scrub for 1 min a...

Embodiment 2

[0044] Preparation of cleaning solution: Add surfactant, cleaning aid, anti-caking agent, solubilizer, wetting agent and pH regulator to deionized water in sequence under continuous stirring, and continue stirring until uniform. The content of each component is: surfactant (Pingajia-O) 5wt%, cleaning aid (sodium hexametaphosphate) 0.5wt%, caking inhibitor (polyacrylamide) 5wt%, solubilizer (acetone ) 15wt%, wetting agent (perfluorooctane sulfonate ammonium) 0.1wt%, pH regulator (ammonium bicarbonate) 2wt%; the pH value of the cleaning solution is 8.7.

[0045] Cleaning method: the polishing pad is scrubbed with deionized water once every 30 minutes of use; the polishing pad is scrubbed with the cleaning solution of the present invention once every 2 hours of use. Specifically: dilute the prepared cleaning solution by 30 times, use an ordinary PVA brush to scrub the polished non-woven polishing pad for 2 minutes at a flow rate of 3L / min, and then use deionized water to wash the...

Embodiment 3

[0047] Preparation of cleaning solution: Add surfactant, cleaning aid, anti-caking agent, solubilizer, wetting agent and pH regulator to deionized water in sequence under continuous stirring, and continue stirring until uniform. The content of each component is respectively: surfactant (octylphenol polyoxyethylene ether) 10wt%, cleaning aid (sodium tetrapolyphosphate) 5wt%, caking inhibitor (sodium polyacrylate) 3wt%, solubilizer ( Isopropanol) 10wt%, wetting agent (perfluorooctane sulfonate amine) 0.01wt%, pH regulator (isopropanolamine) 5wt%; the pH value of the cleaning solution is 10.0.

[0048] Cleaning method: scrub the polishing pad with deionized water once every 30 minutes of use; scrub the polishing pad with the cleaning solution of the present invention once every 1.5 hours of use. Specifically: dilute the prepared cleaning solution by 40 times, use an ordinary PVA brush to scrub the polished non-woven polishing pad for 1.5 minutes at a flow rate of 3L / min, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com