Film formation device

A film-forming device and film-forming chamber technology, which can be used in spraying devices, liquid spraying devices, and devices that apply liquid to surfaces, etc., which can solve the problems of many film-forming situations and difficulty in using large-area substrates, and achieve low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

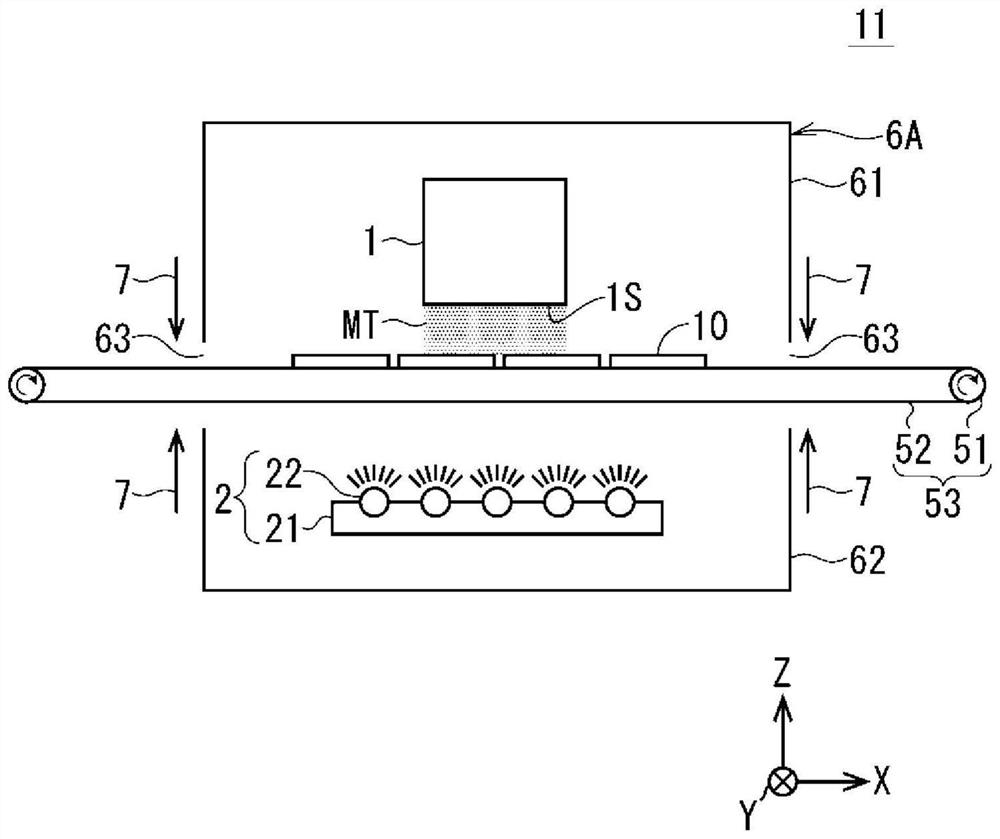

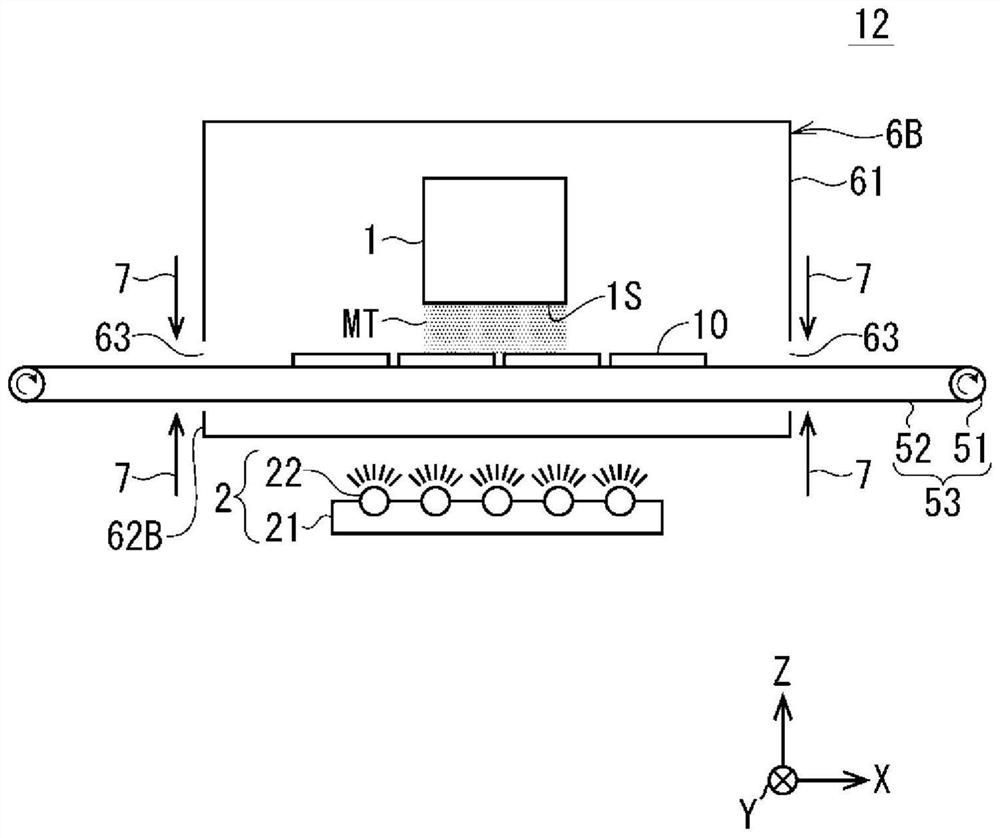

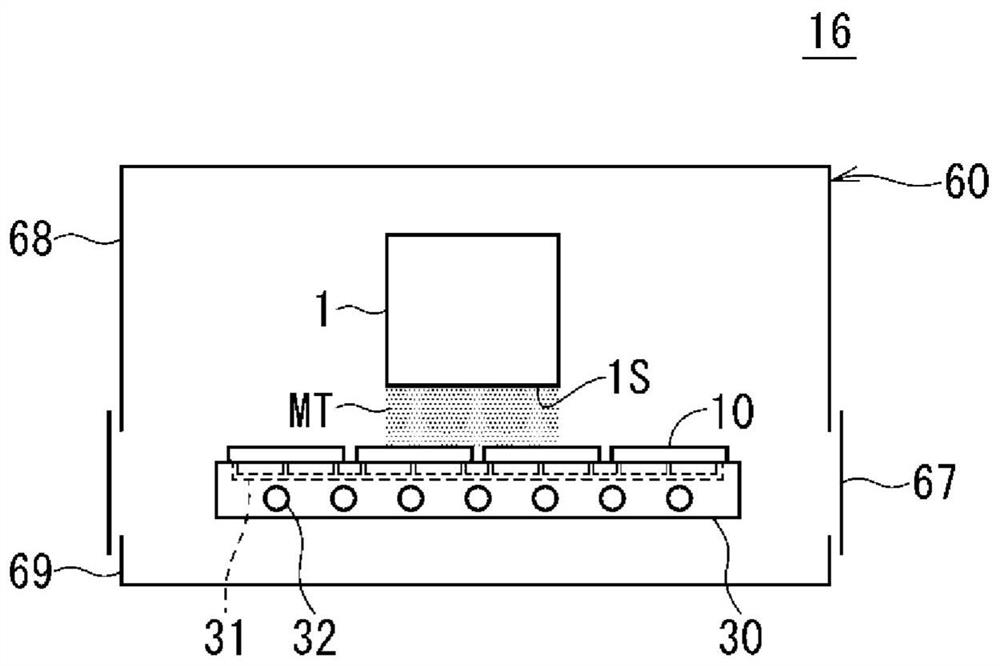

[0030] figure 1 It is an explanatory diagram showing a schematic configuration of a film formation apparatus according to Embodiment 1 of the present invention. exist figure 1 The XYZ orthogonal coordinate system is described in .

[0031] like figure 1 As shown, the film forming apparatus 11 according to Embodiment 1 includes a film forming chamber 6A, a thin film forming nozzle 1 , an infrared light irradiator 2 , and a conveyor 53 as main components.

[0032] The conveyor 53 serving as a substrate loading unit places a plurality of substrates 10 on the upper surface of the belt 52 . The conveyor 53 includes a pair of conveying rollers 51 provided at both left and right (−X direction, +X direction) ends, and an endless conveying belt 52 stretched over the pair of rollers 51 .

[0033] The conveyor 53 can move the belt 52 on the upper side (+Z direction side) along the conveyance direction (X direction) by rotationally driving the pair of rollers 51 .

[0034] The pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com