Steel surface rust removal method

A technology of steel and rust remover, which is applied in the direction of grinding machines, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of not meeting the requirements of steel rust removal, affecting the service life of steel, and taking a long time for steel rust removal. Good rust effect, improve product quality, comprehensive effect of rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

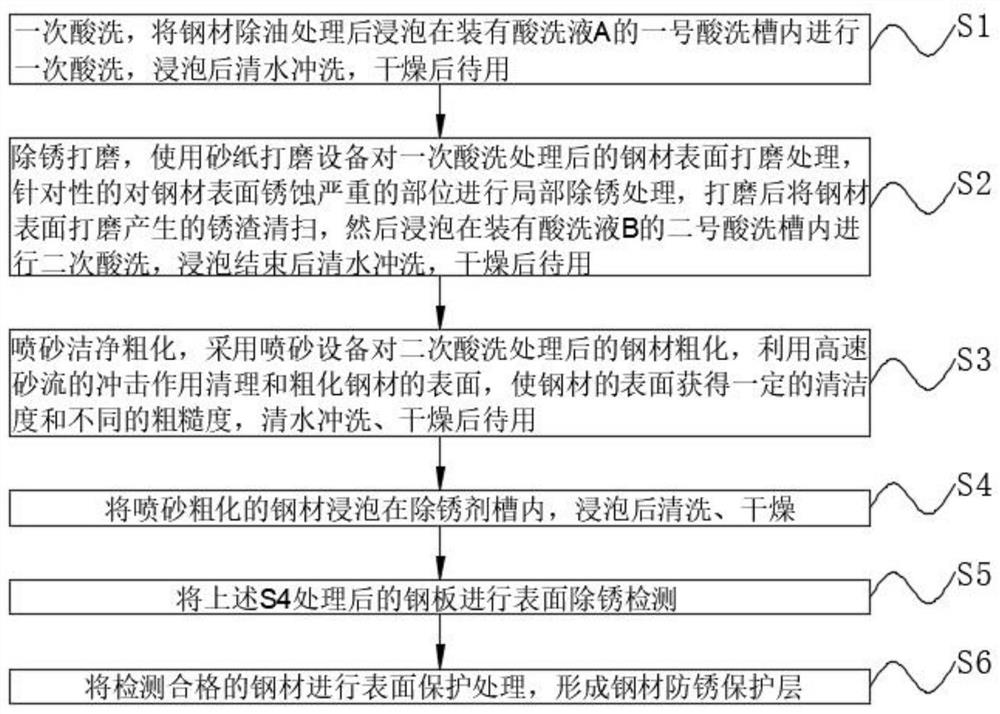

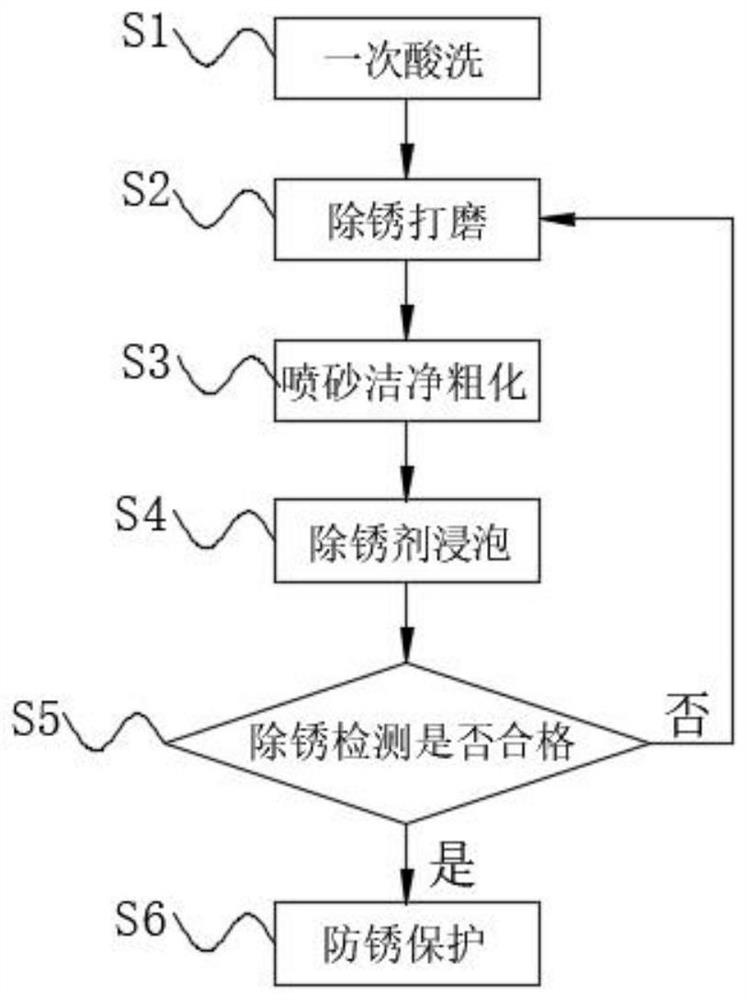

[0025] Such as Figure 1-2 As shown, the present embodiment adopts the following technical scheme: a method for removing rust on the surface of steel, the method for removing rust comprises the following steps:

[0026] S1, a pickling, after the steel is degreased, soak it in the No. 1 pickling tank equipped with pickling solution A to carry out a pickling, rinse it with water after soaking, and dry it for use;

[0027] S2. Rust removal and grinding. Use sandpaper grinding equipment to grind the steel surface after a pickling treatment, and carry out local rust removal treatment on the heavily corroded parts of the steel surface. After grinding, clean the rust residue generated by the steel surface grinding. Then soak in No. 2 pickling tank equipped with pickling liquid B to carry out secondary pickling, rinse with clear water after soaking, dry and set aside;

[0028] S3. Sandblasting cleaning and coarsening, using sandblasting equipment to roughen the steel after the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com