Intelligent optimization method for spray gun tracks of steel box girder sandblast derusting parallel robot

A technology of sandblasting, rust removal and intelligent optimization, applied in abrasive jet machine tools, instruments, artificial life, etc., can solve problems such as difficulty in real-time detection, narrow the search range, improve global search capabilities and search efficiency, and improve sandblasting removal. The effect of rust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

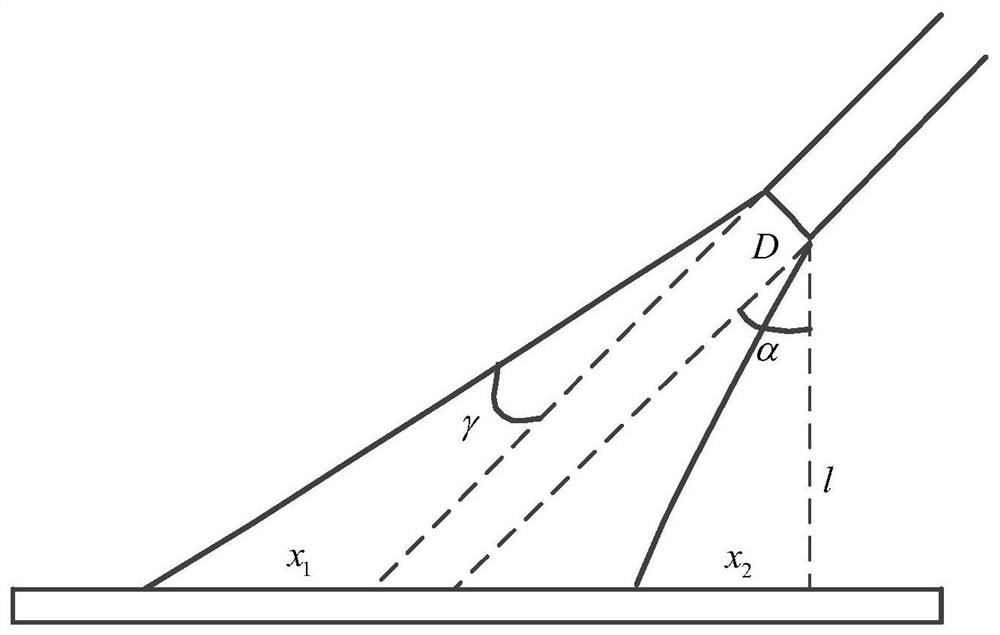

[0024] Such as Image 6 As shown, firstly, for steel box girder sandblasting and derusting parallel robot sandblasting and derusting operations, multivariate fitting is used to establish a surface roughness model that reflects the relationship between spraying distance, spraying angle, spraying gun moving speed and surface roughness of spray gun trajectory parameters. Then, based on the surface roughness prediction model, set the constraint conditions to ensure that the surface roughness meets the process requirements, and take the sandblasting efficiency as the optimization goal to establish a spray gun trajectory parameter optimization model, and optimize and solve the best spray gun trajectory parameters; further , based on the piecewise modeling of the complex curved surface of the steel box girder, the minimum containment box of each pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com