Efficient cyclic tracking flexible correction plate feeding machine

A board feeding machine and flexible technology, applied in the direction of conveyors, conveyor objects, household components, etc., can solve the problems of easy deflection, poor quality, and low efficiency of boards, so as to ensure the quality of edge banding, improve efficiency, and reduce The effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

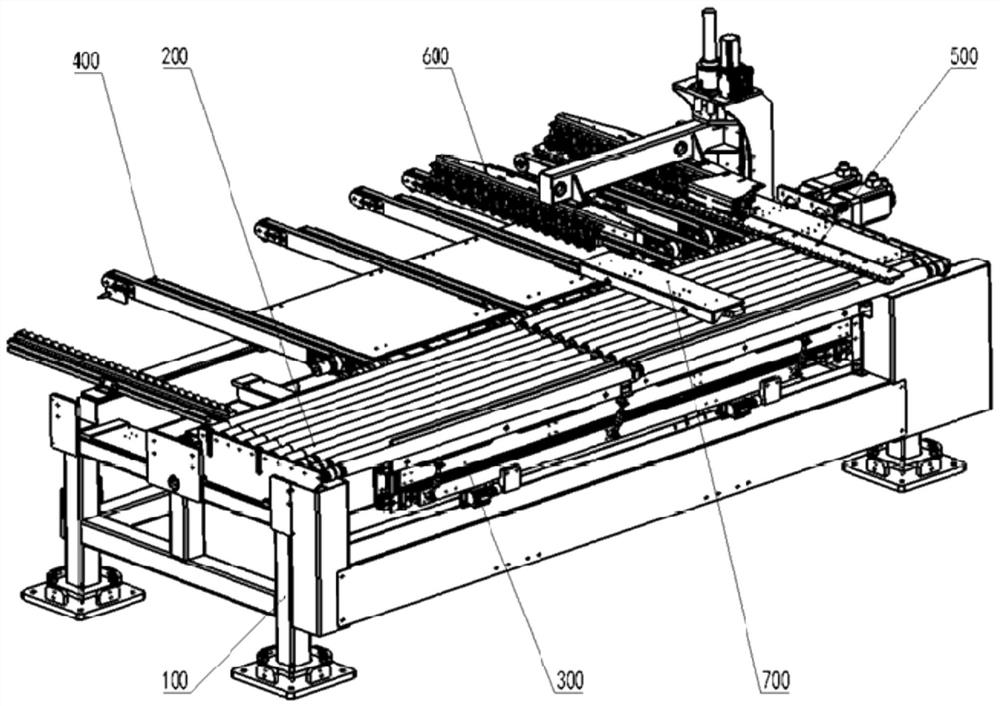

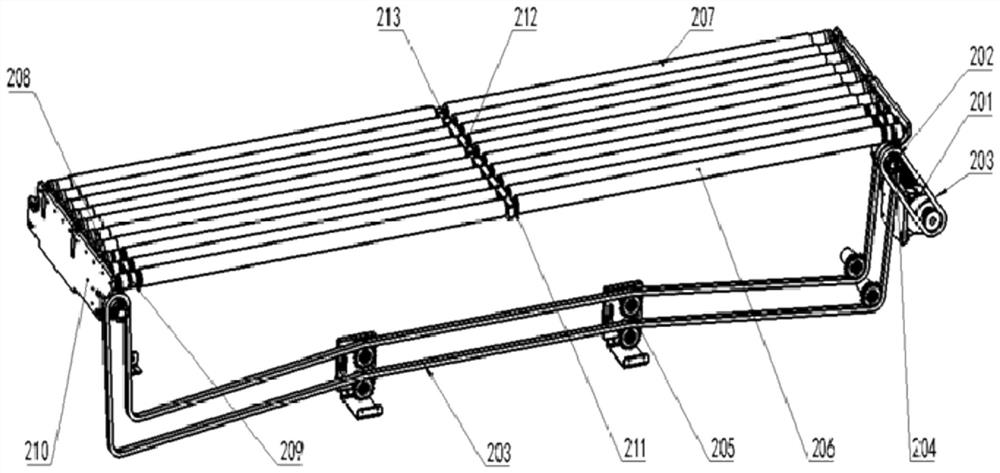

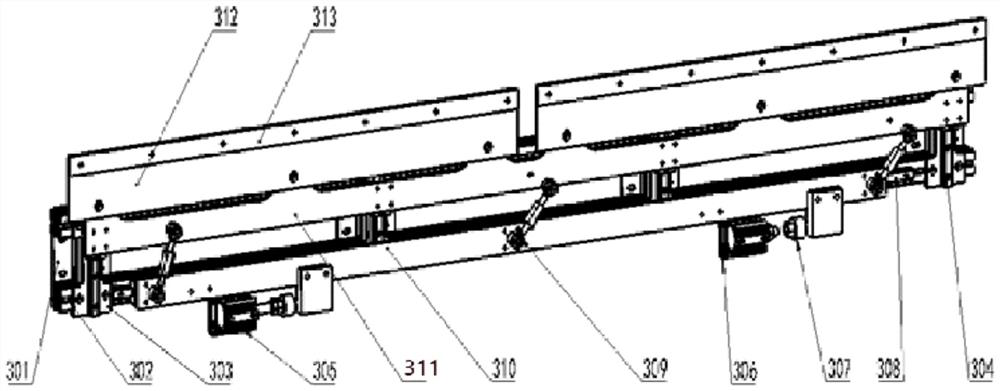

[0034] This embodiment provides a high-efficiency circular tracking flexible correction board feeding machine, the structure is as follows figure 1 As shown, including a frame 100, the frame 100 is respectively provided with a roller conveying mechanism 200, an intelligent baffle 312 mechanism 300, a synchronous belt conveying mechanism 400, a flexible stopper mechanism 500, a flexible pressure roller mechanism 600, and a flexible square calibration mechanism 700, the roller conveying mechanism 200 is installed on the side above the frame 100 close to the plate, the flexible square calibration mechanism 700 is installed between the roller conveying mechanism 200 and the frame 100, and the flexible stopper mechanism 500 is installed on the side of the frame 100 One side is parallel to the board feeding direction, the flexible pressure wheel mechanism 600 is installed on the side above the frame 100 with the flexible stop mechanism 500, and extends to the top of the synchronous b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com