Electric power material loading and unloading device

A technology for loading and unloading devices and power materials, which is applied in transportation and packaging, load hanging components, springs/shock absorbers, etc. The effect of transportation and smooth handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

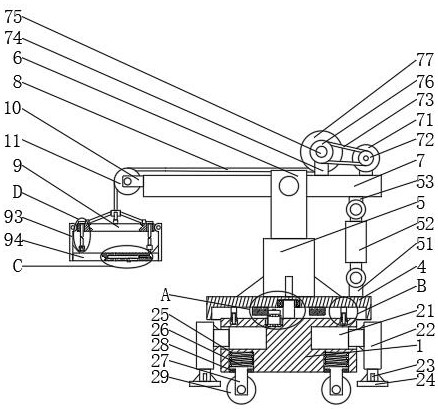

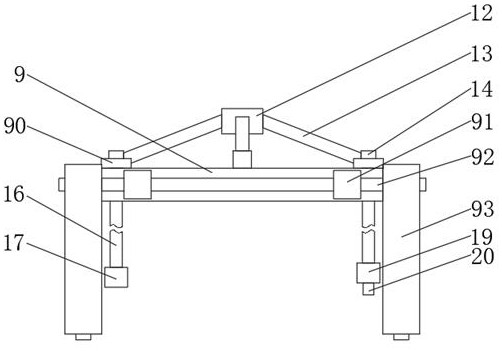

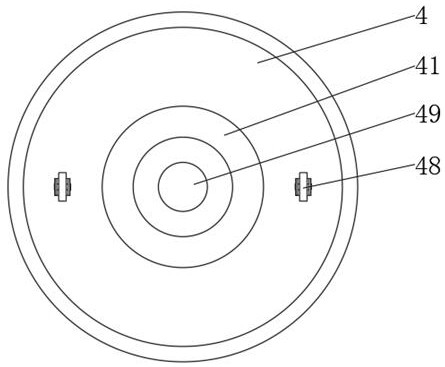

[0027] A power material loading and unloading device, comprising a base 1, a fixed shaft 2, a bearing 3, a turntable 4, a cylinder barrel 5, a cylinder rod 6, a hoisting rod 7, a steel rope 8, a hoisting plate 9 and a bracket 1 10, characterized in that: The upper end of the base 1 is fixedly connected with a fixed shaft 2, the upper end of the fixed shaft 2 is rotatably connected with a bearing 3, the outer side of the bearing 3 is fixedly connected with a turntable 4, and the upper end of the turntable 4 is welded with a cylinder barrel 5, so The inside of the cylinder barrel 5 is slidably connected with a cylinder rod 6, the upper end of the cylinder rod 6 is hinged with a hoisting rod 7, the left end of the hoisting rod 7 is fixedly connected with a bracket one 10, and the left end of the bracket one 10 is rotatably connected with a Pulley 11, the outer side of the pulley 11 is slidably connected with the steel rope 8, the lower end of the steel rope 8 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com