Environment-friendly automatic operation platform integrated with workover main engine and usage method

A work platform and workover technology, applied to drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of low coordination efficiency of make-up and breakout hydraulic tongs, low positioning efficiency and accuracy, time-consuming and labor-intensive problems, etc. Achieve the effect of reducing the difficulty and cost of positioning, fast and accurate positioning, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

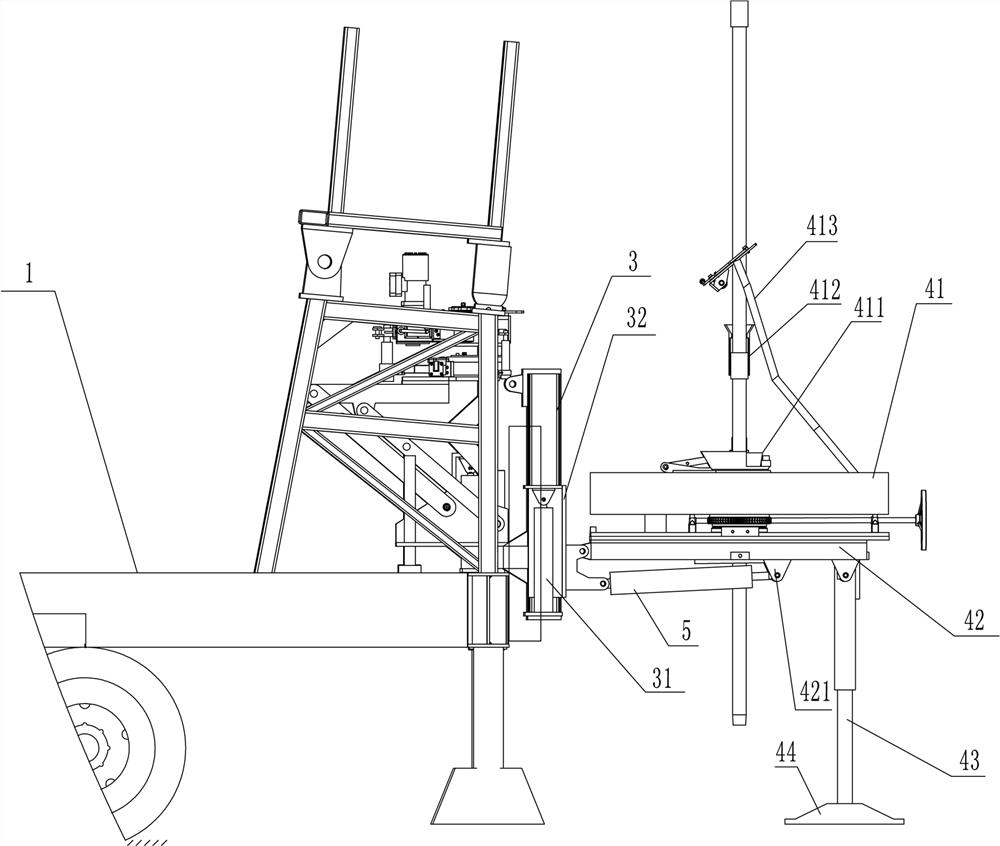

[0059] The above-mentioned use method of the environmental protection automatic operation platform 4 integrated with the workover host includes the following steps:

[0060] S1, under the guidance of the operator, drive the workover truck 1 to the wellhead operation position, control the retraction of the folding oil cylinder 5 through the control system of the workover host on the workover truck 1, level the operation platform 4, and open the lower surface of the operation platform 4 The directing light 45 and the camera device 46 are used to locate the central through hole and the wellhead of the work platform 4 through the light spot emitted by the circular pointing light 45, and the real-time picture is captured by the camera device 46 and sent to the control room in the workover vehicle 1 for viewing. positioning;

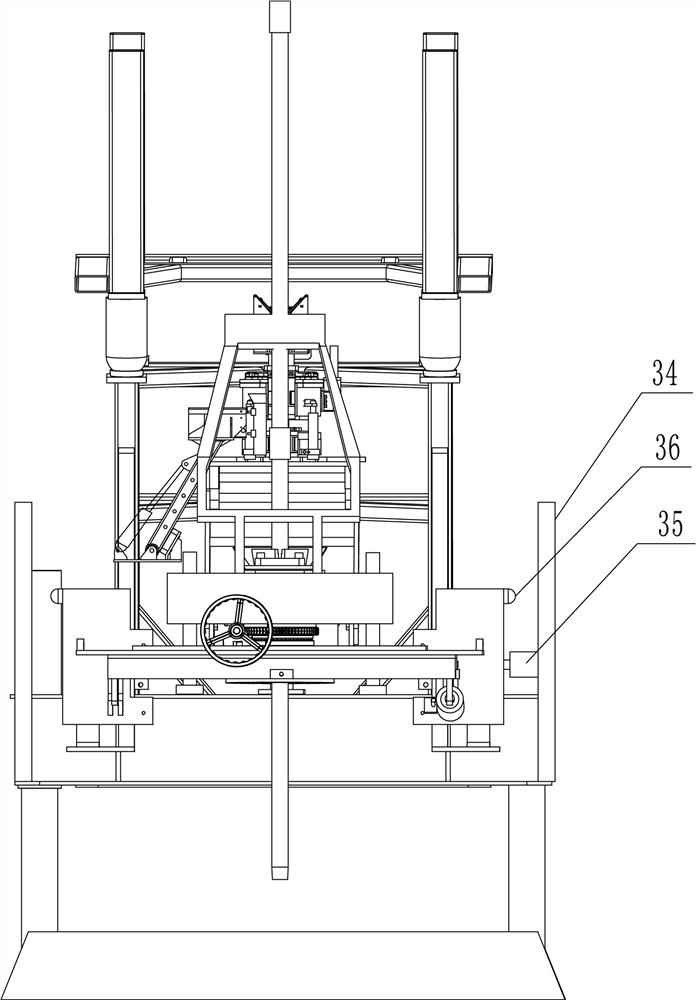

[0061] S2, adjust the stroke of the fourth adjusting oil cylinder 35 through the control system to make the working platform 4 adjust the longitudinal positio...

Embodiment 3

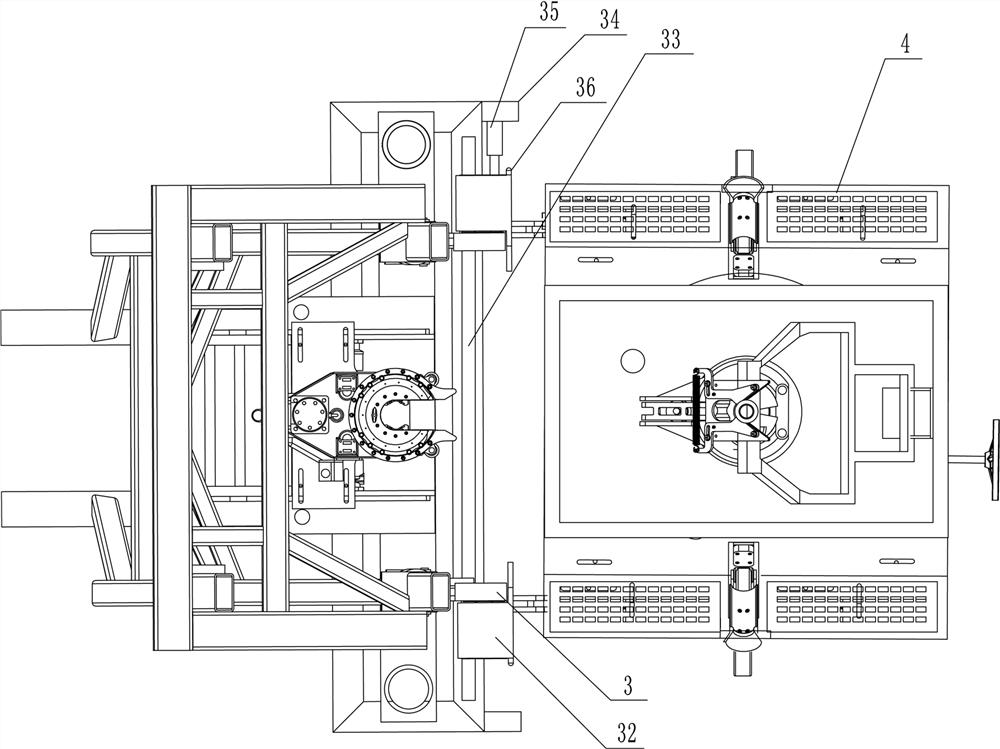

[0068] like Figure 10 As shown, the driller is located on one side of the workover main engine, and the catwalk and pipe rack placement area 6 is located on the opposite side of the driller. At this time, the working surface 41 is rotated to make the pipe support mechanical device face the catwalk and pipe rack placement area 6-1 side.

Embodiment 4

[0070] like Figure 11As shown, the driller is located on the side of the workover host, and the catwalk and pipe rack placement area 6 is behind the workover host. At this time, the work surface 41 is rotated to make the pipe support mechanism face the catwalk and pipe rack placement area 6-1 side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com