Two-stage turbine booster pump

A turbocharged, two-stage technology, applied in pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve the problem of inability to operate continuously for a long time, low work efficiency, and no energy recovery. equipment and other problems, to achieve the effect of reducing water production energy consumption and water production cost, saving operation time, and saving physical energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

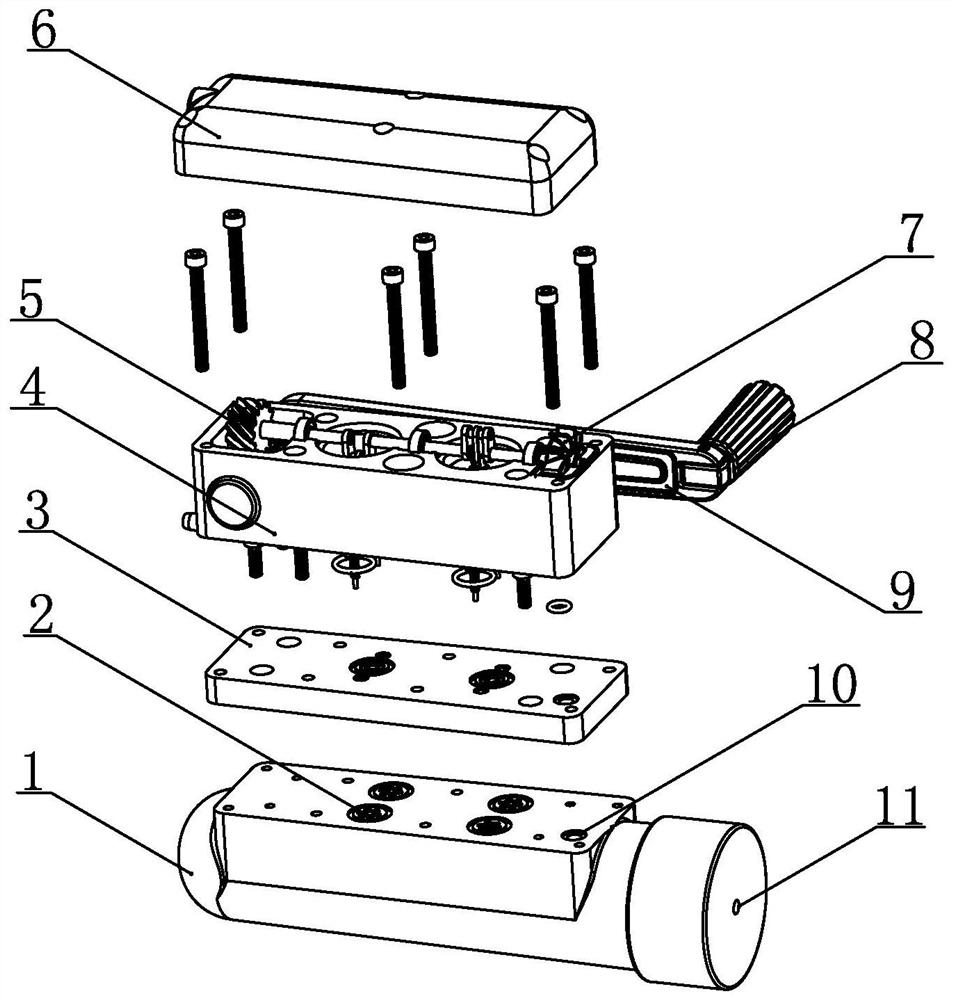

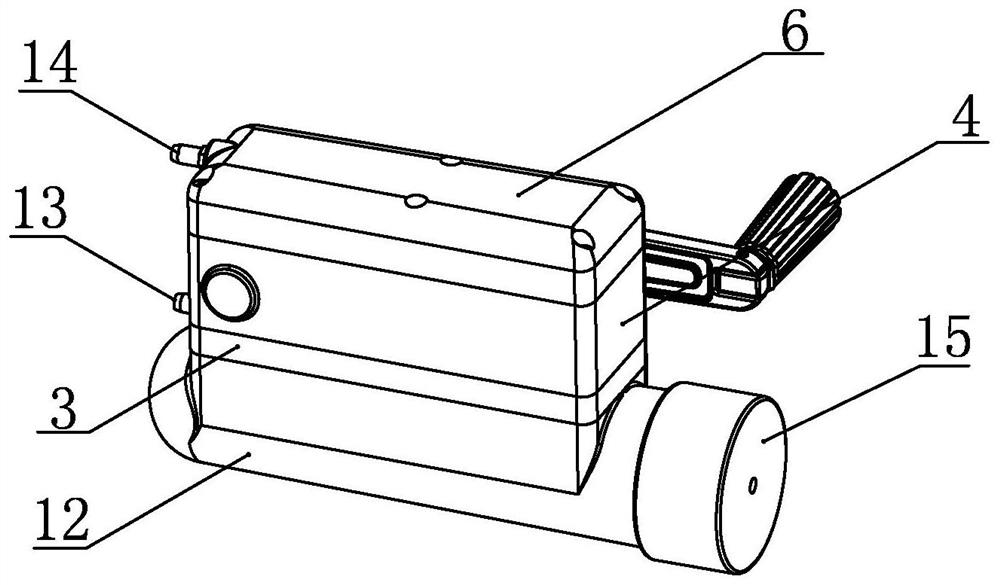

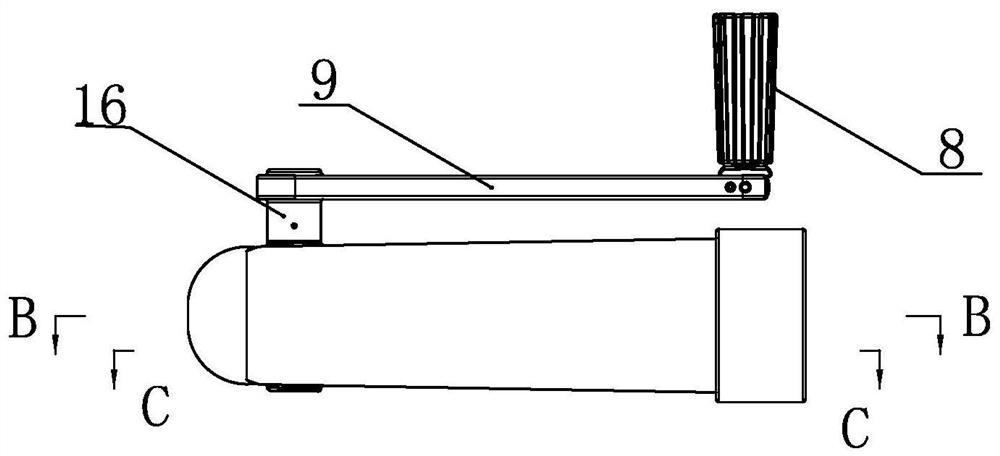

[0031] Such as figure 1 and figure 2 As shown, the two-stage turbocharger pump of the present invention includes a pump body 4 , a pump seat 3 , a handle 8 and a filter assembly 1 . The handle 8 is internally connected with the pump body 4, and power is provided for the cylinder in the pump body 4 by shaking the handle 8. A cylinder is arranged inside the pump body 4 for pressurizing the water entering the cylinder. The pump body 4 and the pump base 3 are connected by bolts, the pump base 3 is located under the pump body 4, the pump base 3 is provided with a water inlet port 13, and the water inlet port 13 is connected to a water source. The filter assembly 1 is connected with the pump base 3 , and the filter assembly 1 is arranged under the pump base 3 for filtering water pressurized by the pump body 4 .

[0032] Such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com