Pretreatment method of ceramics membrane of reverse osmosis for desalting seawater

A ceramic membrane and pretreatment technology, which is applied in seawater treatment, osmosis/dialysis water/sewage treatment, reverse osmosis, etc., can solve the problems of high cost of seawater desalination pretreatment, high energy consumption in operation, and low seawater recovery rate, etc., to achieve Thin separation layer, high throughput and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

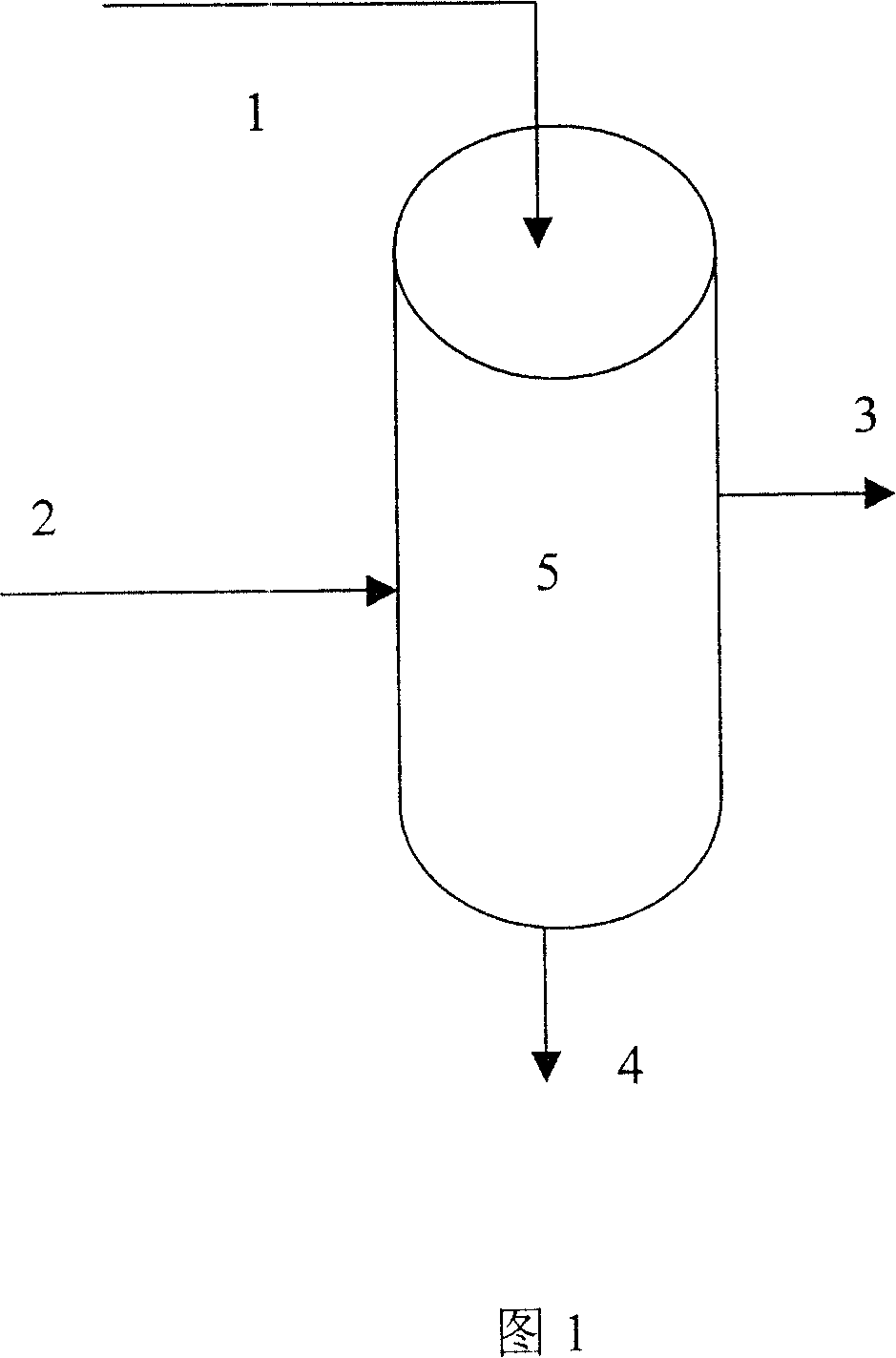

Image

Examples

Embodiment 1

[0021] A ceramic membrane terminal filtration pretreatment method in the reverse osmosis seawater desalination process, which includes firstly using NaClO to sterilize and kill algae in the fresh seawater in the sedimentation tank, adding ferric chloride for flocculation and sedimentation, and using a multi-media filtration system to remove the Flocculated suspended solids, etc., the effluent enters the activated carbon filter, the activated carbon filtered liquid is pressurized to 0.05MPa and then enters the ceramic membrane terminal filtration unit. The turbidity of the effluent after the ceramic membrane terminal filtration pretreatment is 0.08NTU, and all indicators reach reverse osmosis. Membrane system requirements.

[0022] In this pretreatment system, the ceramic membrane is Al 2 O 3 Material, nominal pore diameter is 500nm, shape is 19-channel circular tube, single membrane module, 3 stages in series.

Embodiment 2

[0024] A ceramic membrane terminal filtration pretreatment method in the reverse osmosis seawater desalination process, which includes first using NaClO to sterilize and kill algae in the fresh seawater in the sedimentation tank, and the effluent is pressurized to 0.1MPa and then enters the ceramic membrane terminal filtration unit, and passes through the ceramic membrane The turbidity of the effluent from the terminal filtration pretreatment is 0.1NTU, and all the indicators meet the requirements of the reverse osmosis membrane system.

[0025] In this pretreatment system, the ceramic membrane is made of ZrO 2 , The nominal pore diameter is 200nm, the shape is 19-channel circular tube, single membrane module, 3 stages in series.

Embodiment 3

[0027] A ceramic membrane terminal filtration pretreatment method in the reverse osmosis seawater desalination process, which includes firstly using NaClO to sterilize and kill algae in the fresh seawater in the sedimentation tank, adding ferric chloride for flocculation and sedimentation, and using a multi-media filtration system to remove the Flocculated suspended solids, etc., the effluent enters the activated carbon filter, the activated carbon filter liquid is pressurized to 0.3MPa and then enters the ceramic membrane terminal filtration unit. The turbidity of the effluent after the ceramic membrane terminal filtration pretreatment is 0.05NTU, and all indicators reach reverse osmosis. Membrane system requirements.

[0028] In this pretreatment system, the ceramic membrane is Al 2 O 3 Material, nominal pore size is 200nm, shape is 19-channel circular tube, single membrane module, 5 stages in series.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com