Wear-resistant and corrosion-resistant coating for compensation type manual valve

A technology of anti-corrosion coating and manual valve, which is applied in the field of valve wear resistance, can solve problems such as extension, and achieve the effects of avoiding stress peeling, obvious effect, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

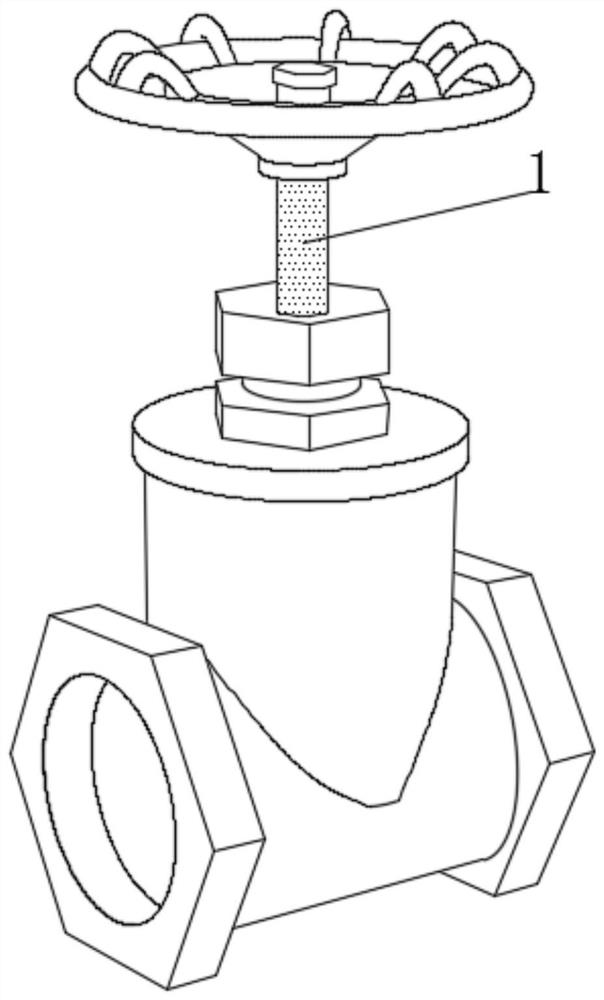

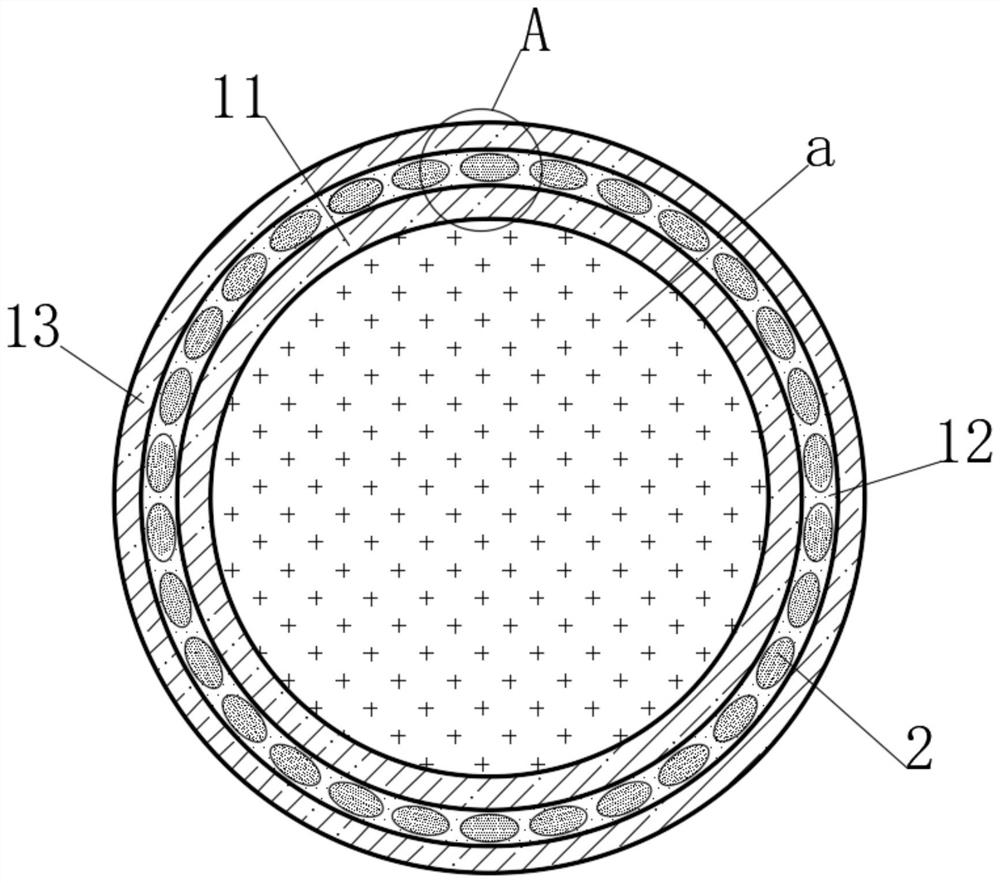

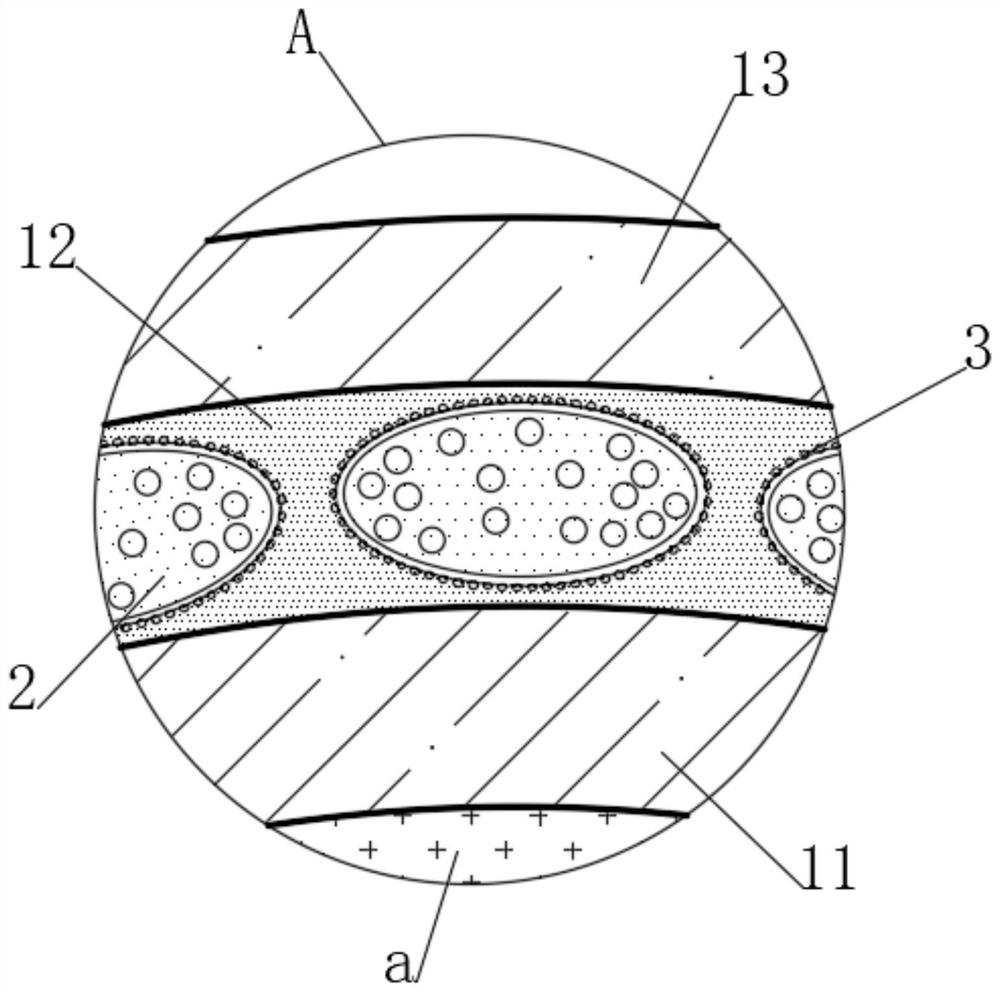

[0040] see Figure 1-2 , a in the figure represents the valve stem, a wear-resistant and anti-corrosion coating for a compensated manual valve, including a coating body 1 coated on the outer surface of the valve stem, and the coating body 1 includes an inner coating coated on the outer surface of the valve stem The anti-corrosion layer 11, the outer surface of the inner anti-corrosion layer 11 is coated with an anti-corrosion interlayer 12, the outer surface of the anti-corrosion interlayer 12 is coated with an outer anti-corrosion layer 13, and the anti-corrosion interlayer 12 is made of a micro-elastic material. When it is deformed, it can undergo a certain adaptive deformation, so that part of the force can be removed, so that the impact resistance of the coating is strong. , so that when the force is large, the internal air-hardening material will flow out in time, and the thickness of the anti-corrosion interlayer 12 is not less than 1 / 3 of the thickness of the coating bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com