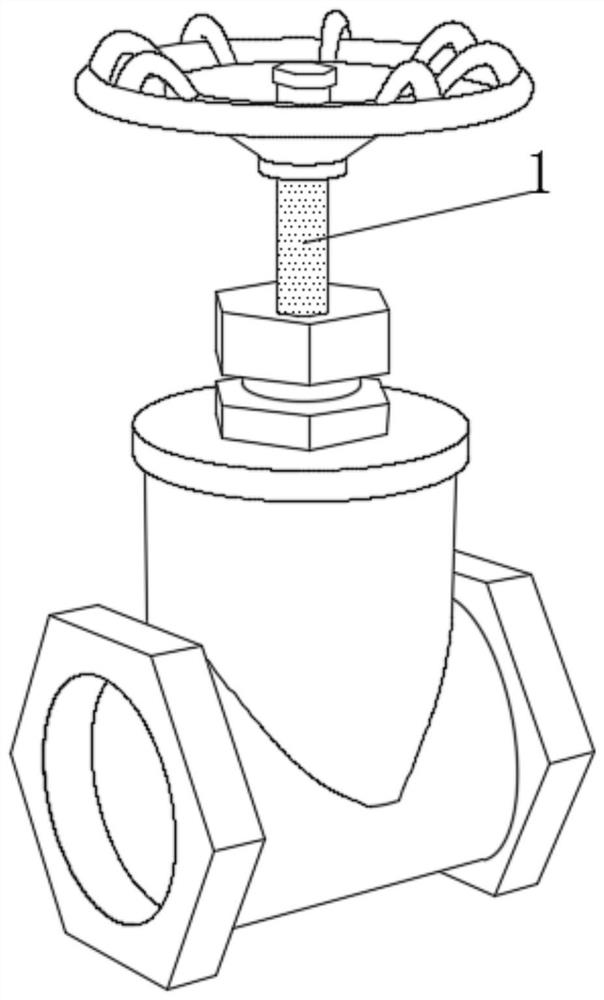

A wear-resistant and anti-corrosion coating for compensating manual valves

An anti-corrosion coating, manual valve technology, used in the field of valve wear, can solve problems such as extension, and achieve the effect of improving strength, improving structural strength, and strong impact resistance.

Active Publication Date: 2022-05-31

丽水红宇阀门有限公司

View PDF14 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

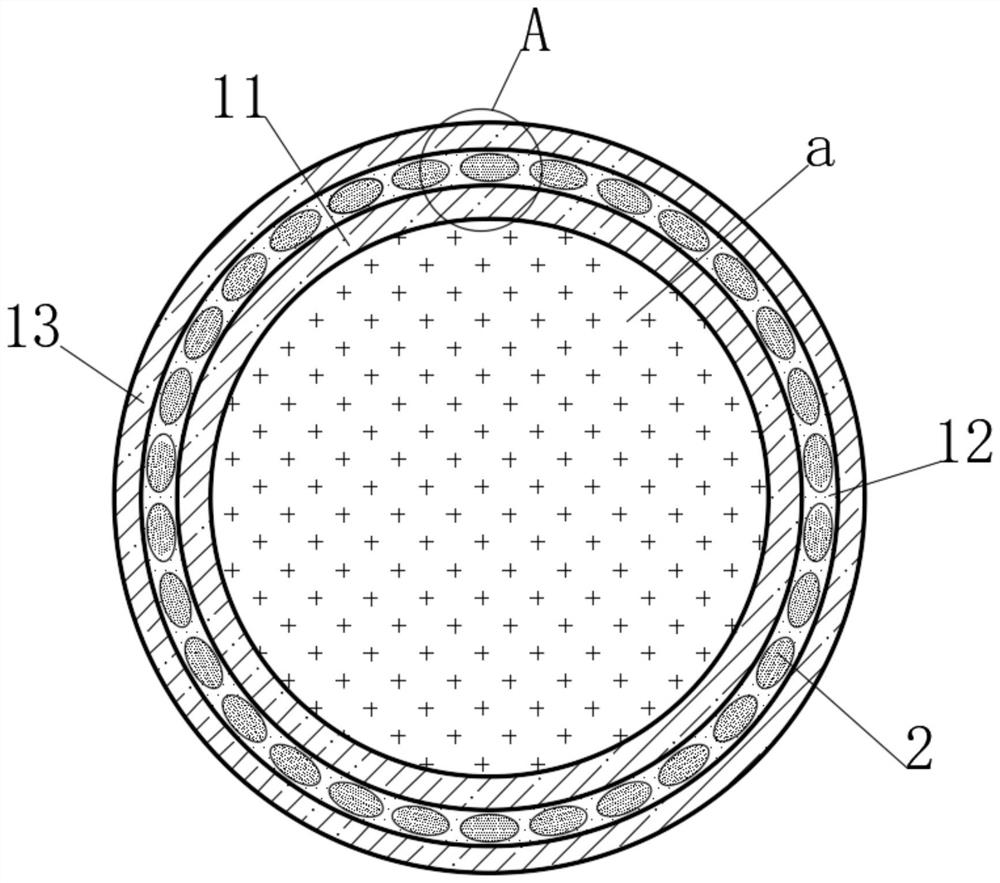

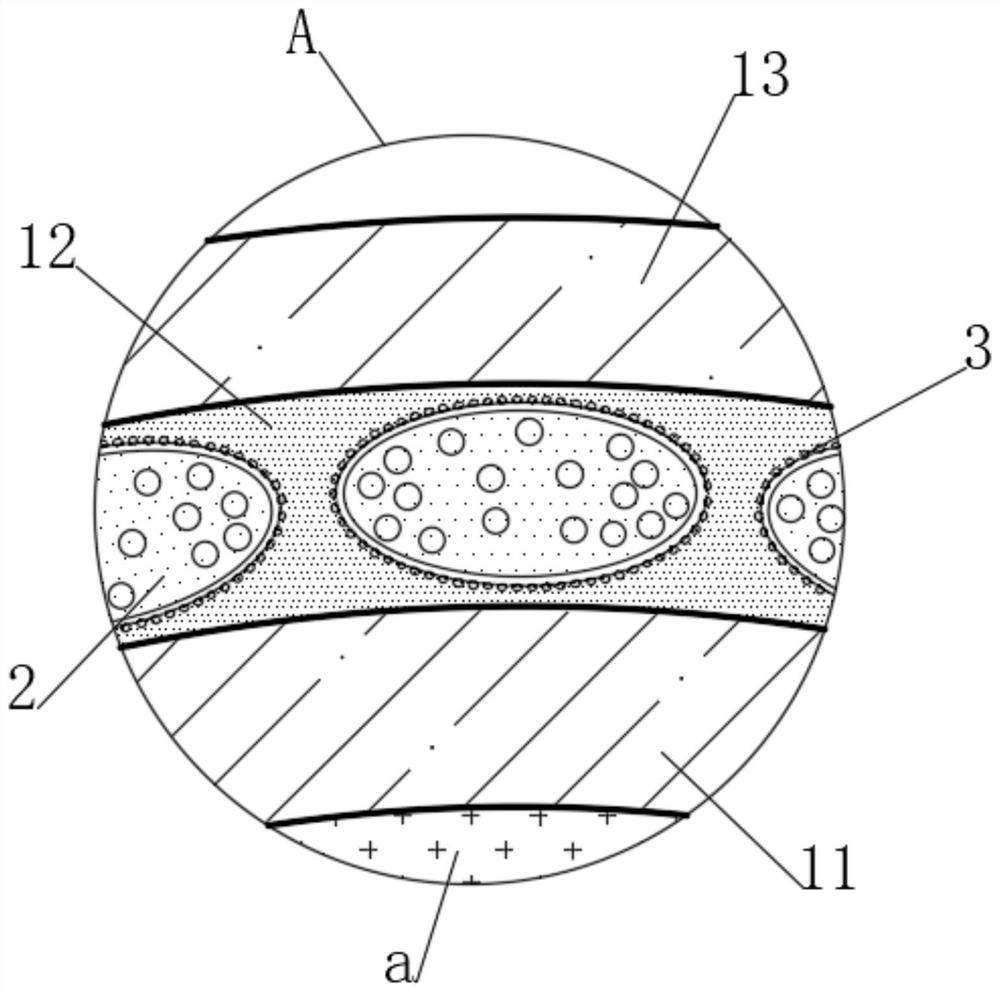

[0005] Aiming at the problems existing in the prior art, the object of the present invention is to provide a wear-resistant and anti-corrosion coating for a compensation type manual valve, which can be adjusted when the local force is too large through the cooperation of the inner compensating oblate ball and the inner half-repelling ball. , the embedded semi-repelling sphere will move towards the inner compensating oblate sphere, and pierce the inner compensating oblate sphere, so that the air-hard material flowing out from the inner compensating oblate sphere at a fixed point, and hardens under the action of the air in the self-compensating cavity , so as to achieve the effect of fixed-point compensation for the position where the coating is subjected to greater force, effectively improve the structural strength of the coating on the valve, and then effectively avoid the occurrence of skinning due to force, and at the same time cooperate with the function of porous branch line fluff, which can improve The strength of the hardened air-hardening material makes it less prone to accidental breakage when the part is stressed again, thereby maintaining and extending the effect of fixed-point compensation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a wear-resistant and anti-corrosion coating for a compensation type manual valve, which belongs to the field of wear resistance of valves. A wear-resistant and anti-corrosion coating for a compensation type manual valve can be used in the field of wear-resistant and anti-corrosion coatings through the cooperation of internal compensation flat balls and embedded semi-repellent balls. When the local force is too large, the embedded semi-repelling ball will move towards the inner compensating oblate ball, and puncture the inner compensating oblate ball, so that the air-hard material flowing out from the inner compensating oblate ball at a fixed point, and the air in the self-compensating cavity Under the action of the valve, hardening occurs, so as to achieve the effect of fixed-point compensation for the position of the coating under greater force, effectively improve the structural strength of the coating on the valve, and thus effectively avoid the occurrence of peeling due to force, and at the same time cooperate with the porous branch line The function of fluff can improve the strength of the hardened air-hardening material, making it less prone to accidental fragmentation when the part is stressed again, thereby maintaining and prolonging the effect of fixed-point compensation.

Description

A kind of compensation type manual valve wear-resistant and anti-corrosion coating technical field [0001] The present invention relates to the field of valve wear, more specifically, to a wear-resistant and anti-corrosion coating for a compensation type manual valve. Background technique Anti-corrosion coating refers to a kind of coating that is coated on the metal surface to isolate it from the surrounding medium to control pipeline corrosion. cover layer. It should have good electrical insulation and water resistance, strong adhesion to the surface of the pipeline, resistance to chemical damage and a certain mechanical strength. Anti-corrosion coatings are often composed of three parts: the first layer is a primer applied to the metal surface to strengthen the metal and The adhesion of the main coating; the second layer is the main coating, commonly used materials are coal tar enamel, petroleum asphalt, polyethylene adhesive Belts, epoxy resins, polyolefin coatin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16K31/44F16K51/00B05D7/00B05D7/24

CPCF16K31/44F16K51/00B05D7/00B05D7/24B05D7/58Y02A20/20

Inventor 张尚斌

Owner 丽水红宇阀门有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com