Anti-bubble defect lead-free glaze

An anti-bubble and lead-free glaze technology, applied in the field of lead-free glaze, can solve problems such as bubble defects and reduce the quality of ceramic preparation, and achieve the effects of reducing bubble defects, inhibiting polymerization and growth, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

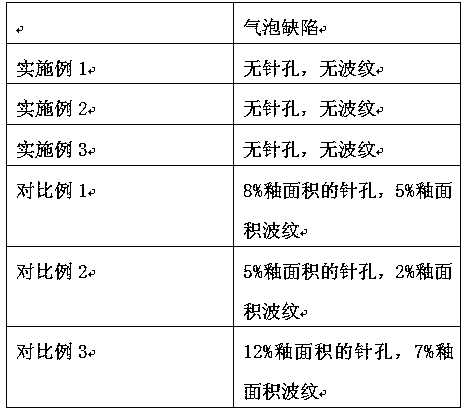

Examples

Embodiment 1

[0020] A lead-free glaze for preventing bubble defects, said lead-free glaze for preventing bubble defects contains 5.8% active sericite by mass.

[0021] Further, the preparation method of the active sericite is:

[0022] (1) Grinding the sericite and passing through a 1800 mesh sieve to obtain sericite powder;

[0023] (2) Heat 200g of the above-obtained sericite powder: 300mL of weak base solution with a mass fraction of 2.5% in a water bath to 95°C, then add thiourea with a mass fraction of 1.8% of the sericite powder, and stir at a speed of 500r / min 2 hours, then filter and dry to constant weight;

[0024] (3) Dissolve potassium phosphate in deionized water to prepare a potassium phosphate solution with a mass concentration of 25.8%. Heat the potassium phosphate solution to 58°C and keep it warm for 15 minutes. Sodium 3-chloro-2-hydroxypropanesulfonate, continue to heat to 72°C, stir at 500r / min for 2 hours, then ultrasonically treat for 2min, then cool to 12°C for crys...

Embodiment 2

[0031] A lead-free glaze for preventing bubble defects, the said lead-free glaze for preventing bubble defects contains 10.5% active sericite by mass.

[0032] Further, the preparation method of the active sericite is:

[0033] (1) Grinding the sericite and passing through a 1800 mesh sieve to obtain sericite powder;

[0034] (2) Heat the sericite powder obtained above to 230g: 300mL of weak base solution with a mass fraction of 2.5% in a water bath to 95°C, then add thiourea with 1.8% mass of sericite powder, and stir at a speed of 500r / min 2 hours, then filter and dry to constant weight;

[0035] (3) Dissolve potassium phosphate in deionized water to prepare a potassium phosphate solution with a mass concentration of 25.8%. Heat the potassium phosphate solution to 58°C and keep it warm for 15 minutes. Sodium 3-chloro-2-hydroxypropanesulfonate, continue to heat to 72°C, stir at 500r / min for 2 hours, then ultrasonically treat for 2min, then cool to 12°C for crystallization, ...

Embodiment 3

[0042] A lead-free glaze for preventing bubble defects, the said lead-free glaze for preventing bubble defects contains 8.5% active sericite by mass.

[0043] Further, the preparation method of the active sericite is:

[0044] (1) Grinding the sericite and passing through a 1800 mesh sieve to obtain sericite powder;

[0045] (2) Put 210g of the sericite powder obtained above: 300mL of a weak base solution with a mass fraction of 2.5%, heat it in a water bath to 95°C, then add thiourea with a mass fraction of 1.8% of the sericite powder, and stir at a speed of 500r / min 2 hours, then filter and dry to constant weight;

[0046](3) Dissolve potassium phosphate in deionized water to prepare a potassium phosphate solution with a mass concentration of 25.8%. Heat the potassium phosphate solution to 58°C and keep it warm for 15 minutes. Sodium 3-chloro-2-hydroxypropanesulfonate, continue to heat to 72°C, stir at 500r / min for 2 hours, then ultrasonically treat for 2min, then cool to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com