Method and device for evaluating contribution degree of chemical system in-situ emulsification to improvement of crude oil recovery ratio

A technology of contribution degree and recovery factor, which is applied in the field of evaluating the contribution degree of chemical system in-situ emulsification to enhanced oil recovery factor, and can solve problems such as the lack of quantitative contribution test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] This example is to illustrate the use of the device of the present invention to evaluate the contribution of chemical system in-situ emulsification to enhanced oil recovery.

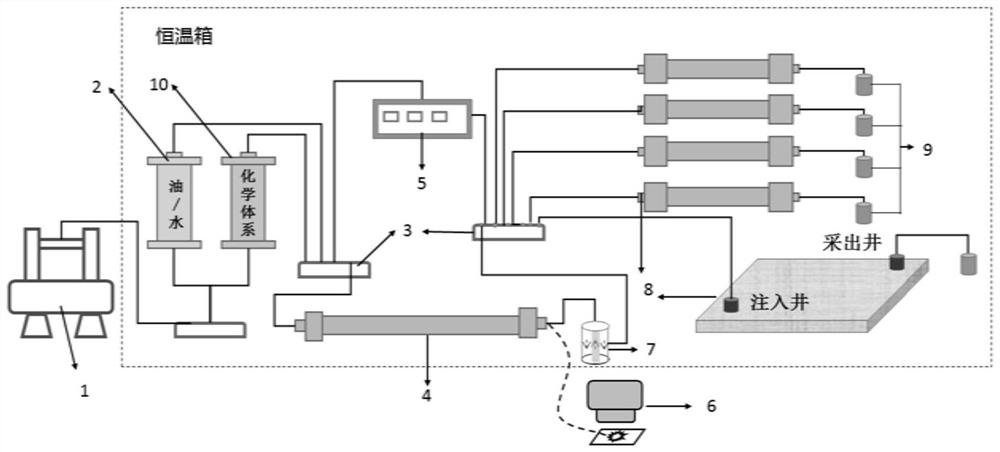

[0090] use figure 1 device shown.

[0091] In the chemical system: the polymer is partially hydrolyzed polyacrylamide with a relative molecular weight of about 19 million, the concentration is 1500mg / L; the surfactant is petroleum sulfonate KPS used in Xinjiang Oilfield, the concentration is 0.5%; the crude oil is taken from Xinjiang Oilfield, stored Viscosity 18mPa at layer temperature 43°C . s; the interfacial tension between the chemical system and crude oil is 8×10 -3 mN / m. The first core model uses an artificial core model of 4.5cm×4.5cm×30cm, with an average permeability of 500mD and a porosity of 21.5%; the second core model is a cylindrical natural core with a gas permeability of 282mD, a diameter of 2.5cm, and a length of 7.5cm , and its porosity is 20.8%.

[0092] (1) Vacuumize the ...

Embodiment 2

[0104] This example is to illustrate the use of the device of the present invention to evaluate the contribution of chemical system in-situ emulsification to enhanced oil recovery.

[0105] use figure 1 device shown.

[0106] In the chemical system: the polymer is partially hydrolyzed polyacrylamide with a relative molecular weight of about 25 million, the concentration is 1500 mg / L, the surfactant is petroleum sulfonate DPS used in Dagang Oilfield, the concentration is 0.5%, and the crude oil is taken from Dagang Oilfield. Viscosity 51mPa at layer temperature 53°C . s, the interfacial tension between the chemical system and crude oil is 4×10 -3 mN / m. The first part uses an artificial core model of 4.5cm×4.5cm×30cm, with an average permeability of 500mD and a porosity of 21.3%; the second part uses an artificial homogeneous flat sandstone model with a size of 4.5cm×30cm×30cm and a permeability of 2000× 10 -3 mD, the schematic diagram of the model is shown in Figure 5 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com