Preparation method of small-size groove

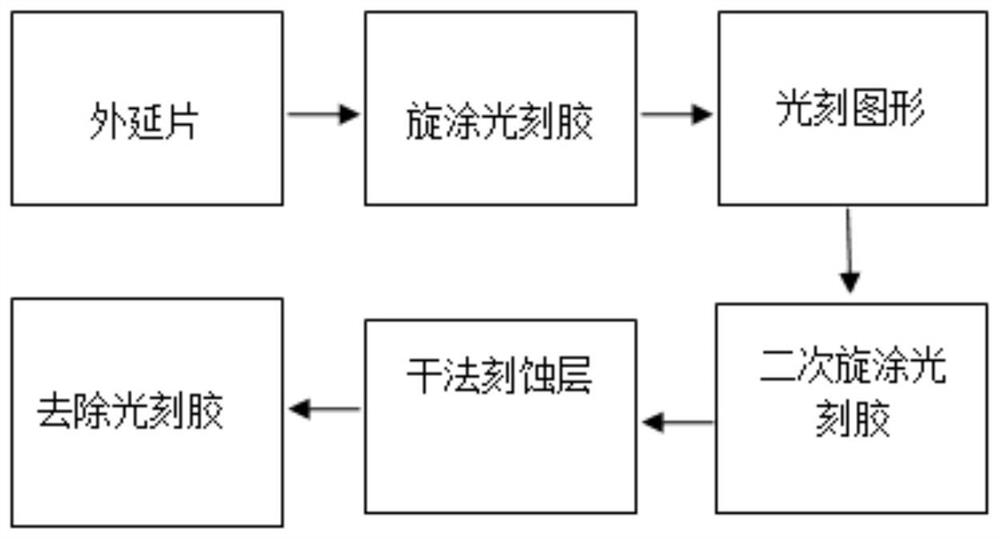

A small-scale, grooved technology, used in photoengraving process coating equipment, patterned surface photoengraving process, opto-mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

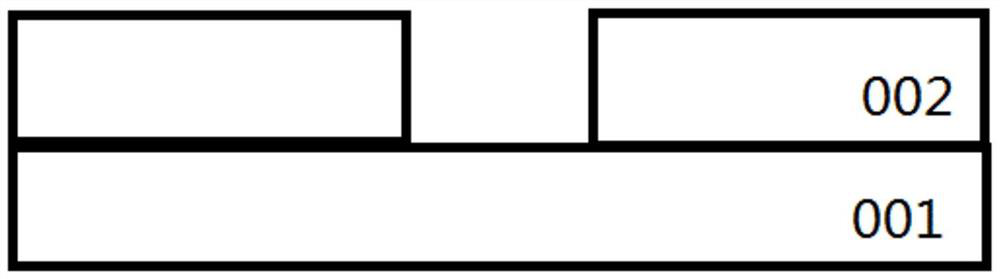

[0057] Step 1: Prepare the chip first;

[0058] Step 2: spin-coat photoresist again, and spin-coat a layer of positive photoresist on the surface of the prepared chip epitaxial wafer to form a photoresist layer; then bake the chip to remove the solvent in the photoresist; The thickness of the resist layer is

[0059] Step 3: Then use the photolithographic mask to expose the photoresist layer, and then remove the exposed part of the photoresist by developing, and photoetch the required pattern photoresist on the epitaxial wafer, wherein the photolithographic mask The pattern width in is 10 μm;

[0060] Step 4: Put the treated chips in an oven and bake at 90°C for 5 minutes;

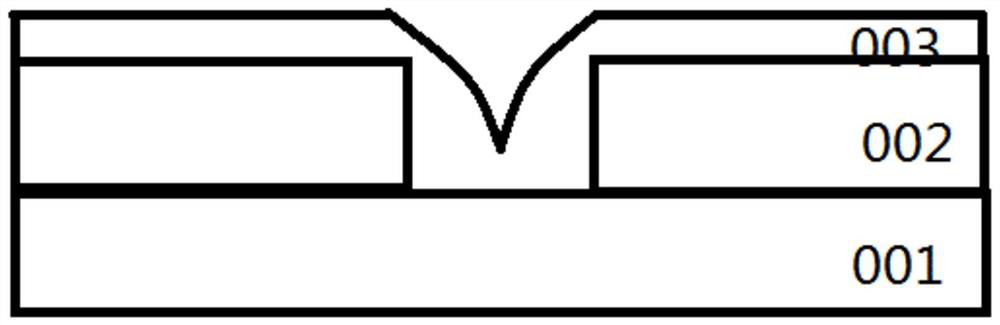

[0061] Step 5: Next, spin-coat the photoresist for the second time, take the baked chip, and spin-coat a layer of positive photoresist on the surface of the photoresist layer to form a photoresist mask layer with a groove-shaped radian; The chip is baked again to remove the solvent in the photoresist;...

Embodiment 2

[0066] Step 1: Prepare the chip first;

[0067] Step 2: spin-coat photoresist again, and spin-coat a layer of positive photoresist on the surface of the prepared chip epitaxial wafer to form a photoresist layer; then bake the chip to remove the solvent in the photoresist; The thickness of the resist layer is

[0068] Step 3: Then use the photolithographic mask to expose the photoresist layer, and then remove the exposed part of the photoresist by developing, and photoetch the required pattern photoresist on the epitaxial wafer, wherein the photolithographic mask The pattern width in is 18 μm;

[0069] Step 4: Put the treated chips in an oven to bake, the baking temperature is 100°C, and the baking time is 10 minutes;

[0070] Step 5: Next, spin-coat the photoresist for the second time, take the baked chip, and spin-coat a layer of positive photoresist on the surface of the photoresist layer to form a photoresist mask layer with a groove-shaped radian; The chip is baked ag...

Embodiment 3

[0075] Step 1: Prepare the chip first;

[0076] Step 2: spin-coat photoresist again, and spin-coat a layer of positive photoresist on the surface of the prepared chip epitaxial wafer to form a photoresist layer; then bake the chip to remove the solvent in the photoresist; The thickness of the resist layer is

[0077] Step 3: Then use the photolithographic mask to expose the photoresist layer, and then remove the exposed part of the photoresist by developing, and photoetch the required pattern photoresist on the epitaxial wafer, wherein the photolithographic mask The pattern width in is 25 μm;

[0078] Step 4: Put the treated chips in an oven and bake at 110°C for 15 minutes;

[0079] Step 5: Next, spin-coat the photoresist for the second time, take the baked chip, and spin-coat a layer of positive photoresist on the surface of the photoresist layer to form a photoresist mask layer with a groove-shaped radian; The chip is baked again to remove the solvent in the photoresis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com